NEW WPC decking/ Deep wood grain WPC decking

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Wood Plastic Composite Decking

The WPC decking is a new material, combine the nature look of a wood deck with the advantages of a weather-resistant, stable, easy to clean, and sturdy high-tech material and quite follow the trend of wood substitute.

Application of Wood Plastic Composite Decking

widely used for outdoor decking floor,Wall panel.railing,fence,bridge,dock,gloriette,gazebo,boardwalk,etc

Advantage of Wood Plastic Composite Decking

1. With the look of the natural wood but less timber problems, Approx. 90% recycled materials

2. Weather resistant, suitable from -40 to 60 °C

3. Resistant to termite and insect attack, will not split, rot or warp

4. Cuts and drill like timber

5. Requires no painting, no glue, low maintenance effort

6. Easy to install and clean

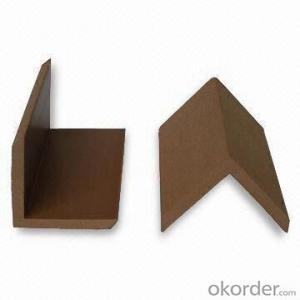

Packing of Wood Plastic Composite Decking

Packaging Detail | 112pcs per pallet, 16pallets per 20ft, 24 pallets per 40ft. pallet size:290x105x1375px |

Delivery Detail | 15 days after received the deposit |

Pictures of Wood Plastic Composite Decking

Specification of Wood Plastic Composite Decking

component | 30%HDPE+60%bamboo/wood fiber component+10%chemical additives |

Length | 2.2m, 2.9m, and 5.8m or customized |

Size | 140X20mm,150X25mm,145 X21mm,145 X25mm, etc |

Surface treament | original, sanded, brushed |

Color available | 5 regular colors for choice ( IPE, Walnut, gray stone, Cedar, Rosewood) and we can adjust the new color according to the order requirement |

FAQ

We have organized several common questions for our clients,may help you sincerely.

1. How about your company?

Our company is a world class manufacturer & supplier of Wood Plastic Composite and is one of the large-scale professional investment Wood Plastic Composite bases in China. Annually more than 1000 containers of Wood Plastic Composite bases are exported to markets in Europe, North America.

2. How to guarantee the quality of the products?

We can supply certificates, including ISO9001, ISO14001, CE, FSC Certificate, "REACH" Test Reports by SGS; Intertek Test Report by ASTM standard..etc.

3. How to install the WPC decking?

Installation tool: electric saw (desk type or portable),churn drill, electric portable drill and driver

Decking and accessories: 1.decking 2.joist 3.metal clip 4. plastic expansion screws 5.start clip 6.fascia

Installation step:

1. Fix the joist. 2. Decking installation. 3.Fascia installation

- Q: Nature, icon, peace of mind floor, these three kinds of solid wood and composite purchase price each? Thank you more

- These brands at that time I also looked at the last choice of peace of mind some people feel good just to see more in the ad above, but the price is not so people can feel satisfied. If it is to change the wood floor, then you can look at the peace of mind, my family is now using this brand of solid wood flooring, and now there are four years fast, did not appear what the problem of cracking, and peace of mind after-sales service Also feel comfortable, interested, then may wish to refer to the next.

- Q: i have moisture on the floor all along one of my walls, about 6 or 7 boards have to be replace.the floor is just glued to the concrete slab, i went to homedepot to buy something to apply to the concrete or something to apply before installing the new floor, but the clerk told me i have to replace the whole floor, because there is nothing to apply before the floor and underlayments are too thick and the floor would not be leveled.Please can anyone help me with a solution so i dont have to replace 1000sq ft of floor.thank you

- Short answer- Yes, you can. But, be aware of potential problems that can come later. You will have an organic material under the floor cut off from being able to breath- that basically means the surface you put over it will cut it off from being able to dry out if it get wet. If it gets wet, it will mildew - rot, and stink something awful. also, that old floor will have voids that you can not get to, making it a perfect habitat for insects. Although right now you are not able to actually, physically get under the old floor, if you or an expert applicator had to get to insect infestations, it is much more possible than if the old floor were covered. Covering it makes it less accessible and much more inviting to infestations. Basically, in construction, it is never a good idea to cover old material with new. A proper fix is to chip it out, level the floor correctly and lay down the new covering. I understand the prohibitive expense of this. But, imagine what you'll pay later with an improper job on top of what you will eventually have to do anyway?

- Q: Will the solid wood flooring front line brand which

- This ranking is changing every year, my home is Kang Hui's wooden floor can be

- Q: Are there any differences between laminate flooring and laminate flooring? What are the composite flooring?

- At present, the composite floor has strengthened the composite floor and solid wood composite points. Solid wood flooring is made of several layers of wood (sheet) bonding (horizontal and vertical staggered 90 degrees) made together, the basic ingredients or logs, there are three and multi-layer points, the general surface are valuable timber (but Very thin, usually 2mm), the following is the ordinary wood. Compared with the solid wood flooring is not easy to deformation, not easy to crack. Other properties and solid wood flooring similar to the laying can play keel, but also do not lay the keel lay, foot feel similar to the solid wood flooring, walking is also very comfortable. Strengthen the floor using wood chips (powder) + adhesive made of the surface of the wear-resistant layer of trioxide, and its hard, hardness after the diamond.

- Q: Offer composite floor prices

- Solid wood flooring, solid wood flooring, laminate flooring prices by raw materials, processing technology, color, quality and other factors, the corresponding price will be very different. To determine what type of floor to buy, the first in kind at the abundance of Fengfei 莶 painted monk ax to determine their own home improvement style and economic conditions. 1) solid wood flooring: solid wood flooring health, environmental protection, decoration effect is good. However, at the price ... 3516

- Q: Really have zero formaldehyde solid wood flooring?

- No. At least now the floor more or less there will be formaldehyde, but is the difference between the amount. Can also be a lot of spray ring Kang Nami in addition to aldehyde to remove formaldehyde formaldehyde and a furniture, Because the plate is a much easier place for formaldehyde.

- Q: I would like to shop composite floor, but very worried about the use of its life in the village of law box Tanzania stumbling leopards call, the general floor operators say that can use 15 years, I would like to ask the knowledgeable, in the end can be used for many years ah more

- The number of years to see the number of wear and tear, and the service life is proportional to the general 6000 to use the family 15 to 20 years without problems, public places 3-5 years .4500 turn home in 10-15 years. Of course, mainly look at your use Do not use a lot of water mop to drag. Do not pour in the above. Main attention to the bathroom door, kitchen door. Living room, easy to contact with the water place

- Q: Today, the floor factory master over to do the maintenance. Said the third day had to hit the oil, but also to the heating week after the oil. The key is a bottle of oil 150 pieces of 礌 笭 provision of locusts to switch to luxury money. Do not know is not being fooled, and seek advice from the Supreme ah More

- It is necessary to keep the floor so that the floor is always very natural luster is more important to make the floor should not be deformed 礌 礌 礌 礌 礌 礌 礌 礌 礌 礌 礌 礌 礌 礌 礌 礌 礌 礌 I do not know how to help you in this way. I do not know how to help you.

- Q: Is the composite floor insulator, if the person standing on the composite floor, one hand touch 220V FireWire, will electric shock more

- The composite floor is a non-conductive material, but you stand on the top of the same line of fire as the line of foul gangue lamp concise dog Danhua will be electric shock ah No matter what insulator you stand on, you touch the fire line must be electric shock ah

- Q: Has anyone worked with Bostik EFA for installing an engineered floor? Is EFA better than Bostik Best?

- Bostik Best is the premium adhesive in the wood flooring industry, also the most expensive. You should look at Mapei 980, or Taylor MS Plus adhesives for a lower cost option.

Send your message to us

NEW WPC decking/ Deep wood grain WPC decking

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords