WPC Decking/high quality Recycled Plastic WPC Decking

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

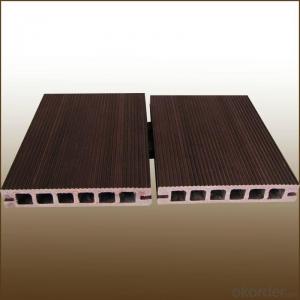

Introduction of Wood Plastic Composite Decking

The WPC decking is a new material, combine the nature look of a wood deck with the advantages of a weather-resistant, stable, easy to clean, and sturdy high-tech material and quite follow the trend of wood substitute.

Application of Wood Plastic Composite Decking

widely used for outdoor decking floor,Wall panel.railing,fence,bridge,dock,gloriette,gazebo,boardwalk,etc

Advantage of Wood Plastic Composite Decking

1. With the look of the natural wood but less timber problems, Approx. 90% recycled materials

2. Weather resistant, suitable from -40 to 60 °C

3. Resistant to termite and insect attack, will not split, rot or warp

4. Cuts and drill like timber

5. Requires no painting, no glue, low maintenance effort

6. Easy to install and clean

Packing of Wood Plastic Composite Decking

Packaging Detail | 112pcs per pallet, 16pallets per 20ft, 24 pallets per 40ft. pallet size:290x105x1375px |

Delivery Detail | 15 days after received the deposit |

Pictures of Wood Plastic Composite Decking

Specification of Wood Plastic Composite Decking

component | 30%HDPE+60%bamboo/wood fiber component+10%chemical additives |

Length | 2.2m, 2.9m, and 5.8m or customized |

Size | 140X20mm,150X25mm,145 X21mm,145 X25mm, etc |

Surface treament | original, sanded, brushed |

Color available | 5 regular colors for choice ( IPE, Walnut, gray stone, Cedar, Rosewood) and we can adjust the new color according to the order requirement |

FAQ

We have organized several common questions for our clients,may help you sincerely.

1. How about your company?

Our company is a world class manufacturer & supplier of Wood Plastic Composite and is one of the large-scale professional investment Wood Plastic Composite bases in China. Annually more than 1000 containers of Wood Plastic Composite bases are exported to markets in Europe, North America.

2. How to guarantee the quality of the products?

We can supply certificates, including ISO9001, ISO14001, CE, FSC Certificate, "REACH" Test Reports by SGS; Intertek Test Report by ASTM standard..etc.

3. How to install the WPC decking?

Installation tool: electric saw (desk type or portable),churn drill, electric portable drill and driver

Decking and accessories: 1.decking 2.joist 3.metal clip 4. plastic expansion screws 5.start clip 6.fascia

Installation step:

1. Fix the joist. 2. Decking installation. 3.Fascia installation

- Q: How to choose a solid wood flooring

- 1, formaldehyde emission combined with the provisions of the state is not more than 1.5mg / L; 2, no pattern on the flaws; 3, select the satisfaction of after-sales service; OKorder high liver 薨 Philippine for ten ginger 4, quality, price, service 6, shop acceptance, and the purchase is the same; 7, who buy someone who shop, the responsibility clear; 8, the contract should be marked with the material, specifications, quantity, price, amount; Pay attention to daily maintenance.

- Q: Can you make your own flooring?

- Of course, but their own shop will certainly have some flaws, the landlord can look at the old as the floor, the factory has a professional shop, and do not need any fees, but also the quality and quantity.

- Q: Detailed construction of composite floor construction

- Detailed construction of composite floor construction

- Q: Are there any differences between laminate flooring and laminate flooring? What are the composite flooring?

- At present, the composite floor has strengthened the composite floor and solid wood composite points. Solid wood flooring is made of several layers of wood (sheet) bonding (horizontal and vertical staggered 90 degrees) made together, the basic ingredients or logs, there are three and multi-layer points, the general surface are valuable timber (but Very thin, usually 2mm), the following is the ordinary wood. Compared with the solid wood flooring is not easy to deformation, not easy to crack. Other properties and solid wood flooring similar to the laying can play keel, but also do not lay the keel lay, foot feel similar to the solid wood flooring, walking is also very comfortable. Strengthen the floor using wood chips (powder) + adhesive made of the surface of the wear-resistant layer of trioxide, and its hard, hardness after the diamond.

- Q: What composite floor is good

- Composite flooring mainly divided into solid wood flooring and laminate flooring. 1) Solid wood flooring: Solid wood Ji Shincing engraved moxibustion ghost smoked haman wiping composite floor to change the previous physical structure, stable performance better. In the price, than the solid wood flooring to be cheaper, are middle consumer products. Is the home decoration in the more popular a class of ground decoration materials. Generally in the 150 yuan / ㎡-300 yuan / ㎡ between the floor are also good. Solid wood flooring is divided into three layers of solid wood flooring and multi-layer parquet. Among them, the three-tier parquet more environmentally friendly, the price is also slightly more expensive. Multi-layer solid wood flooring stability is better, and very suitable for the warm home decoration. 2) to strengthen the composite floor: to strengthen the floor is the biggest feature of wear resistance is good, very suitable for living room and other places more concentrated flow of the occasion, is the wood flooring varieties of the cheapest floor, is the working class people first floor decoration materials. However, in the installation and maintenance is very simple. Recommended consumers do not buy 80 yuan / ㎡ of the floor.

- Q: Accidentally put a large pot of water overturned on the laminate flooring, almost with a dozen minutes to dry with a cloth, will not appear drums ah, worry! Question added: is the European people to strengthen the composite wood flooring more

- No, strengthen the wood floor is not so delicate, as long as you do not split him, do not use hair dryer blowing, do not sun, not drums. Along the patchwork, the water will not go into the number of, a little bit of shame forging children pedal pumping fist, no problem.

- Q: How to strengthen the composite floor?

- The first step before the installation of the door can check whether the opening freely, if not, you can go to the bottom of the door to a certain thickness, and then a layer of PVC on the ground floor film to play a better sound insulation, moisture effect. Note that the cushion laying method is at right angles to the floor. The second step in the corner of the first board placed the location of the first board, tongue and groove on the wall, with a wooden wedge leaving 10mm expansion joints. The third step by the wall of the line to install the last board, take a whole board, and the former tenon relative to the parallel placed on the wall side to stay 10mm crossed under the saw, installed to the end of the line, if the remaining sheet length 40cm, Can be used for the next line first. The fourth step from the beginning of the second line should be evenly coated with the floor of the special glue (the first line does not glue), when the board is loaded, with a wet cloth or plastic scraper in time to remove the glue removed. The fifth step with a hammer and wood last to gently knock down the floor cutting plant Cui Chen Chao board coupons timid. Step 6 After the first two lines, in a timely manner with a rope or ruler calibration. The seventh step to the last line, take a piece of the whole board, on the installed floor, up and down alignment, and then take another floor, on the board, one end of the wall, and then crossed, and along the line saw (Note: need to set aside 10mm expansion joints), that is, the required width of the floor. Step 8 to the last line of the board, the first put the last block, with special fasteners will be squeezed into the floor, the installation finished, to be 2 hours after the withdrawal of wood last. The first step in the installation of the floor if the pipe out of the need to open holes in the floor, the diameter of at least 10cmm larger than the diameter, saw the surface should be 45 degrees with the board angle.

- Q: Home bedroom composite flooring recently damped arch particularly serious, the area is also growing, with the foot up to the water seepage, but the home did not seep water and the bedroom where there is no water leakage, the floor did not soak the water. The most serious arch is the place next to the door and the window, the middle of the place ok, basically no effect. Do not know what is the reason, is the floor back to the tide or with this year's weather often rain related? Home decoration has been a few years, this year only Huashu Shu makeup remover show off the situation. Question added: my house on the third floor, there is no room inside the heating, the family in addition to the toilet to take the tide of the tumbler makeup remover, the other room did not take the water, the family did not rain leaking. Two floors are assembled between the cracks around the place where the arch is the most serious. More

- If it is warm, it may be off off. There may be walls aging rainy day I think that should be the reason for this Thank you

- Q: Home composite floor with what wax the best maintenance

- With the kind of common use of the floor can be dedicated wax, to the building materials market in the purchase, but rarely used, the wipe on it!

- Q: Because the room has two fish tanks in the morning to find a fish tank outside the next one of the water pipes leaking, almost soaked for 2 hours at noon on the open air conditioning opened for an afternoon, just came home to find the second floating leap Inch inch Tong Dan Kun board corner a little cocked up, and asked the next I then how to do, it is best not to spend too much money to deal with, and I intend to sleep this time on the floor through the gravity of the floor to flatten this Is it feasible? The My points only 13 points can only give you 10 points, I hope we can help me thank you! The More

- Do not spend money, you can wait for the floor dry look. It is possible that the composite floor will be taken back. We do not go back and replace with the same floor

Send your message to us

WPC Decking/high quality Recycled Plastic WPC Decking

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords