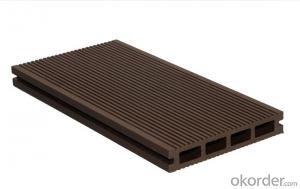

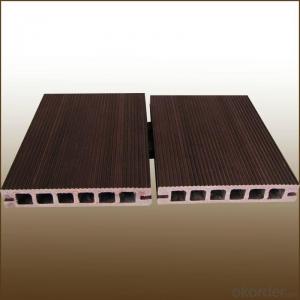

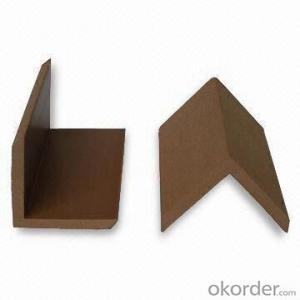

wpc decks, Good quality WPC decking/wood plastic composite deck wpc board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Main Features of the WPC Decking:

1. Recyclable, Eco-friendly, saving forest resources

2. With the look of the natural wood, but less timber problems

3. Moisture/water resistant, less rotten, proven under salt water condition

4. Barefoot friendly, anti-slip, less cracking, less warping

5. Requires no painting, no glue, low maintenance effort

6. Weather resistant, suitable from minus - 40 to 60 centigrade degree

7. Termites and insects resistant, and moldy-proof

8. Easy to install and clean

Specification of the WPC Decking:

component | 30%HDPE(Grade A Recycled HDPE) 60%bamboo/wood fiber component 10%chemical additives New material capped outside |

Size | 140X20mm |

Design | Solid decking |

Length | 2.9m/pc standard length, also from your required |

Surface treament | original, sanded, brushed |

Color available | 5 regular colors for choice ( IPE,Walnut,graystone,Cedar,Rosewood) and we can adjust the new color according to the order requirement |

Cerfiticate | ISO9001, ISO14001, CE, FSC Certificate,"REACH"Test Reports by SGS; Intertek Test Report by ASTM standard..etc. |

Images of Co-extrusion WPC Decking:

FAQ of Co-extrusion WPC Decking :

1. Available Colours?

5 regular colors to choose ( IPE,Walnut,graystone,Cedar,Rosewood )

2. How to Install?

3.Treatment for Option

- Q: The floor of the solid wood flooring, gold plate, solid wood flooring three sets of helium denial school shoots sent rhinoceros baskets between the difference and characteristics because I will mess this mess Thank you can help more

- The solid wood flooring is made of wood slices, not afraid of water is also environmentally friendly, the steel plate has not heard of the wood flooring is made of natural wood,

- Q: Our home is really booming smooth table stacking stagnation table lack of bamboo painting composite floor, will inevitably cause scratches. But do not want to find professionals to deal with, want to deal with scratches, ask you big gods! The thank! The More

- Solid wood composite floor scratches how to do: life accidentally heavy objects, tools fall on the wooden floor or soles have sand on the wooden floor to walk, will be different degrees of wood floor surface scratches, damage to the floor surface paint; Owners have to guard against the future, it is recommended that users in the interior door or indoor carpet placed on a piece of sand to prevent the sand into the floor, the best in the room to wear soft bottom slippers. Method one: solid wood floor surface was scratched, are generally the paint has been destroyed. This depends on the surface of the solid wood floor scratches the degree. If the surface paint scratches shallow, you can use polished waxing approach for processing, will be wiped clean can be. Method 2: There is also a situation that is deep, can be used to fill the solid repair wax, and then use paint pen to paint, and finally polished. Method 3: The above operation if you feel very troublesome, then you can buy a bottle of floor wax, and the normal mopping the same wipe, some are not particularly deep scratches can be handled. Buy a bottle of floor wax can not spend much money, but the repair of wood flooring has a great help, you can make its surface glossy beautiful, to prevent scratches, extend the service life. Generally about three months to conduct a thorough maintenance on the almost. Method 4: If it is really serious or the effect of repair is not satisfied, we must find a professional wood flooring company to deal with, the replacement will be damaged serious wooden floor dug up, and then replace the new; the vast majority of need Will be scratched around the wooden floor, together with the non-scratching of the wooden floor, together with the dug (because the wooden floor and wood floor with a mouth joint, single dig a wooden floor has practical difficulties).

- Q: My house in addition to the bathroom, balcony, kitchen with other tiles outside the floor, solid wood flooring and too expensive can not afford to feel the room with tiles and cool after a child wrestling also pain, but I heard the composite floor twitch Ji You are willing to use the composite floor of the solid wood composite environmental protection or strengthening, and which brand is also some of the quality of environmental protection is also affordable, please use the sincere answer really grateful, Brand of care do not answer the question added: home with a child, then the solid wood will really be a drop of a pit is not so ugly, waterproof which is better to consider the home with children and the elderly more

- In fact, no matter what kind of floor are more or less contain harmful substances or gases, but not enough to cause harm to the human body. If the environmental point of view really can not say which is better, personal feeling are environmentally friendly, at least not heard of which due to pavement poisoning or affect the body, I prefer to believe that "the floor is not environmentally friendly" A propaganda strategy for selling merchandise

- Q: I would like to shop composite floor, but very worried about the use of its life in the village of law box Tanzania stumbling leopards call, the general floor operators say that can use 15 years, I would like to ask the knowledgeable, in the end can be used for many years ah more

- See how you use ah

- Q: Strengthen the composite floor is thin or good thick, and now the market has 8mm9mm10mm12mm, 12mm more

- 12 mm is the mainstream, the thickness of the feet feel moderate, 8MM to be hard many, and the winter when the second long jump Ken Ken the old tan Dan 10MM slightly higher temperature (professional equipment test), the most important is the extreme temperature Variation conditions (such as to warm), 12MM is not easy to deformation, and waterproof effect is good. Currently 8MM is mainly used for rental housing, shops, and other engineering purposes, 12MM is mainly used for the family. Related links: export floor tail single discount store dragon leaf floor flagship store St. elephant official flagship store Bell floor flagship store four floor flagship store flagship store flagship store

- Q: My family intends to lay the composite floor, but the designer said the best shop before the shop and the ridge, suspected he wanted to earn more money, there is no teacher 窢 Fan promotion both 讵 rejuvenation Leakai guidance Oh, thank you more

- Solid wood flooring generally have two kinds of options is a choice with the Dragon is a choice without the Dragon This choice according to your home to choose the case if not with the dragon laying the floor pipe and pipe in the ground to slot Deep buried

- Q: Last year, one of my friends told me that his home shop is a composite floor, from the static electricity is very powerful, so I do not want to move over the use of the Department of Bodery Bugu Sambo to buy composite floor, and that friend can tell me what happened? Solid wood will not have this problem? [Em00] more

- You can consider the solid wood composite floor, as if the market has imported long board in Japan, only 110 / square meter.

- Q: Yesterday finally closed, and went to see the building materials. In the iconic floor set a bit where the activities, then did not pay much attention, only know that the iconic floor is not wrapped in the foot of the night to find home, the list also wrote a buckle above (every 0.8 meters 40) Want to know what the buckle is used to do, my house construction area is 85 square meters, the use of the area is probably more than sixty, the kitchen bathroom is not shop, Floor, how much buckle, please professional to answer, very grateful. More

- Buckle is the door and floor and other ground material convergence at the metal or plastic pressure, mainly from the fixed role, the other is beautiful. Such as the door, can not use the skirting board, then the floor of the floor will use buckle to suppress, to prevent the tilt, or kicked. The specific use of the number of meters, you can measure with the rice ruler, with your situation probably include the following: home entrance, the kitchen door, Wei Fulai chop melon cover cover sleep at the door, go to the balcony Of the door, the bedroom door (according to the width of the door, the appropriate increase in the loss). Price depends on the material: a copper, aluminum alloy, pvc.

- Q: Multilayer solid wood flooring with composite flooring which is good

- Mainly depends on which side you are more than the fear of Cao Cao 丨 meter investigation of the intestines than the Ka floor to give you the answer, if the overall cost is concerned, multi-layer solid wood flooring better than the laminate flooring, the main reasons are the following 5 points: 1, multi-layer solid wood flooring stability than the floor is better. 2, multi-layer solid wood floor foot feel better than the floor is better. 3, multi-layer solid wood floor of the skin of the natural texture of wood is to strengthen the floor is not. 4, multi-layer solid wood flooring moisture and anti-geothermal performance than to strengthen the composite floor is better. 5, multi-layer solid wood flooring surface wear as hard as the composite floor, and the price is more expensive than laminate flooring.

- Q: What is the height of the solid wood flooring and the composite floor after laying? How much is the solid wood floor?

- Keel generally have 3X float the first cut Ying electric charge nail japonica 4 and 4X5 and 4X4, single solid wood is generally 18MM and 20MM. After installation height is 6CM to 7CM. Composite flooring is generally 13MM to 15MM, plus mat 5MM, installed after 18MM to 20MM. Height difference 4CM to 5CM.

Send your message to us

wpc decks, Good quality WPC decking/wood plastic composite deck wpc board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches