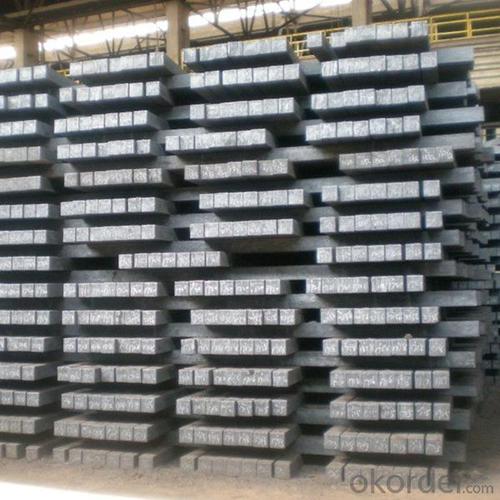

New technology converter continuous casting square steel billet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 800000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

New technology converter continuous casting square steel billet

Grade :GB

Technology : continuous casting

Material :Q235B Q275

Standard :120*120 130*130 150*150 etc .

Length : 6m or 12m or according to your requirement .

Main Parameter

Name | Billet Steel | Delivery time : | ||||||||

Standard | GB/T700-2006 | Consignee : | ||||||||

No. | Oven No. | Material | Specification (mm) | Quantity | Chemical Component (%) | |||||

C | Si | Mn | P | S | Remarks | |||||

1 | 51-3659 | Q235B | 120*120*12000 | 20 | 0.17 | 0.16 | 0.46 | 0.019 | 0.021 | |

2 | 51-3658 | Q235B | 120*120*12000 | 28 | 0.19 | 0.16 | 0.49 | 0.025 | 0.025 | |

3 | 5 Name Billet Steel Delivery time : Standard GB/T700-2006Consignee : No.Oven No.MaterialSpecification (mm)Quantity Chemical Component (%) CSiMnPSRemarks 151-3659Q235B120*120*12000200.170.160.460.0190.021 251-3658Q235B120*120*12000280.190.160.490.0250.025 351-3669Q235B120*120*1200060.170.160.450.0210.019

1-3669 | |||||||||

Quick Details

| Place of Origin: | Shandong, China (Mainland) | Brand Name: | CNBM | Model Number: | CC |

| Grade: | Q235B | Chemical Composition: | C Si Mn P S etc . | Shape: | Square |

| Length: | 6m 12m or according to your requirement, 6m 12m etc | Standard: | GB | Technique: | Cast |

| Dimensions: | 120*120 130 *130 150*150etc | Alloy Or Not: | Is Alloy | Secondary Or Not: | Non-secondary |

| Name: | New technology converter continuous casting square steel billet | Technology: | continuous casting | STANDARD: | GB |

| Material: | Q235B | Specification: | 120*120 130*130 150*150 etc | C: | 0.19 |

| Si: | 0.16 | Mn: | 0.49 | P: | 0.025 |

Packaging & Delivery

| Packaging Details: | in bulk , bundled with iron wire |

| Delivery Detail: | within 10-20days after get your deposit |

- Q: What are the different types of steel billet packaging materials?

- There are various types of steel billet packaging materials available in the market, each with its own unique characteristics and benefits. Some of the commonly used packaging materials for steel billets include: 1. Wooden Crates: Wooden crates are a popular choice for packaging steel billets due to their strength and durability. They provide excellent protection against external impacts and are suitable for long-distance transportation. 2. Steel Strapping: Steel strapping is a strong and secure packaging material that is often used to bundle steel billets together. It provides high tensile strength and resistance to breakage, ensuring that the billets remain intact during handling and transportation. 3. Plastic Wrapping: Plastic wrapping is a cost-effective and lightweight packaging option for steel billets. It offers protection against moisture and dust, preventing any potential damage to the billets. Plastic wrapping can be easily applied and removed, making it a convenient choice for packaging. 4. Steel Framing: Steel framing is a heavy-duty packaging material used for larger and heavier steel billets. It provides maximum protection and stability during transportation, minimizing the risk of any deformation or damage to the billets. 5. Cardboard Boxes: Cardboard boxes are commonly used for smaller steel billets. They are lightweight, easy to handle, and offer sufficient protection against minor impacts and scratches. Cardboard boxes can be customized in various sizes and shapes to accommodate different billet dimensions. 6. Stretch Film: Stretch film is a flexible packaging material that is commonly used to wrap steel billets. It offers excellent protection against moisture, dust, and scratches. Stretch film also provides some level of stability to the billets, preventing any movement during transportation. It is important to consider the specific requirements of the steel billets, such as size, weight, and transportation conditions, when choosing the appropriate packaging material.

- Q: How are steel billets used in the manufacturing of oil and gas components?

- Steel billets are an essential material used in the manufacturing of oil and gas components. These billets are semi-finished products that are typically made through a process called casting, where molten steel is poured into a mold and allowed to solidify into a rectangular shape. Once the steel billets are formed, they are used in various ways to produce components for the oil and gas industry. One common application is in the production of pipes, which are crucial for transporting oil and gas from the reservoirs to the processing facilities or end-users. Steel billets can be further processed to create seamless or welded pipes, depending on the specific requirements of the project. In addition to pipes, steel billets are also used to manufacture other oil and gas components such as valves, fittings, flanges, and pressure vessels. These components are vital for the safe and efficient operation of oil and gas facilities, as they ensure proper flow control, connection, and containment of fluids under high pressures and temperatures. The use of steel billets in the manufacturing of oil and gas components offers several advantages. Firstly, steel is known for its strength, durability, and resistance to corrosion, making it well-suited for the harsh and demanding operating conditions of the oil and gas industry. Additionally, steel billets allow for flexibility in terms of size, shape, and composition, which enables manufacturers to produce components that meet specific project requirements. Overall, steel billets play a critical role in the production of oil and gas components, providing the necessary strength, durability, and versatility required for the safe and efficient operation of the industry.

- Q: What are the main factors affecting the machinability of alloy steel billets?

- The main factors affecting the machinability of alloy steel billets include the composition of the alloy steel, the heat treatment it has undergone, the hardness of the material, the presence of impurities or inclusions, and the cutting parameters used during machining such as cutting speed, feed rate, and depth of cut.

- Q: What are the common sizes of steel billets used in construction?

- The common sizes of steel billets used in construction can vary depending on the specific project and requirements. However, there are several standard sizes that are commonly used in the construction industry. These sizes typically range from 100 mm (4 inches) to 200 mm (8 inches) in width and 100 mm (4 inches) to 300 mm (12 inches) in height. The length of the billets can also vary, but they are often around 6 meters (20 feet) long. These standard sizes are widely available and easily accessible, making them a popular choice for construction projects. However, it is important to note that the actual sizes of steel billets used in construction can be customized based on the specific needs and engineering requirements of a particular project.

- Q: How are the surface defects of steel billets repaired?

- The surface defects of steel billets are repaired through a process called grinding or machining. This involves removing the defective areas by using specialized tools and techniques to smoothen out the surface and make it suitable for further processing or use in various industries.

- Q: Billet prices skyrocketing weekend, Southern China steel prices rose?

- In December 5th, the billet price in Hebei was 2780 yuan per ton, a new high since two years and three months, a rise of more than 85% over the same period of last year.

- Q: What are the main factors affecting the hardness of steel billets?

- The hardness of steel billets is primarily determined by various factors. Firstly, the carbon content plays a vital role in determining steel hardness. Higher carbon content leads to increased hardness as carbon atoms occupy spaces between iron crystals, forming stronger bonds and enhancing material resistance to deformation. Secondly, the inclusion of alloying elements significantly affects steel hardness. Elements like chromium, molybdenum, and vanadium create solid solutions with iron, altering its crystal structure and strengthening the material. These elements facilitate the formation of fine and uniform microstructures, resulting in higher hardness. The heat treatment process is another crucial factor that impacts steel billet hardness. Controlled heating and rapid cooling, such as quenching and tempering, cause a transformation in the crystal structure of steel. This transformation, known as martensitic transformation, increases hardness by generating a high concentration of dislocations and reducing grain size. Furthermore, the cooling rate during solidification also affects steel billet hardness. Rapid cooling, like water quenching, promotes the formation of a fine microstructure and enhances hardness. Conversely, slower cooling rates allow for the growth of larger grains, leading to reduced hardness. Lastly, the presence of impurities and non-metallic inclusions can adversely affect steel billet hardness. These impurities disrupt the crystal lattice, reducing material strength and hardness. Therefore, the purity and cleanliness of the steel composition are crucial for achieving higher hardness levels. In conclusion, several factors, including carbon content, alloying elements, heat treatment processes, cooling rate, and the presence of impurities, influence the hardness of steel billets. To attain the desired hardness properties, it is essential to comprehend and control these factors.

- Q: What are the different methods of steel billet surface plating?

- There are several methods of steel billet surface plating, including electroplating, hot-dip galvanizing, mechanical plating, and chemical plating. Each method offers specific advantages and is used depending on the requirements of the application. Electroplating involves the deposition of a thin layer of metal onto the steel surface through an electric current. Hot-dip galvanizing immerses the steel billet into a bath of molten zinc to create a protective coating. Mechanical plating utilizes mechanical energy to bond a metal coating onto the steel surface. Chemical plating involves a chemical reaction to deposit a metal coating onto the billet surface.

- Q: Can steel billets be used in the production of sculptures and artwork?

- Yes, steel billets can be used in the production of sculptures and artwork. Steel is a versatile and malleable material that allows artists to create unique and intricate designs. The use of steel billets in sculptures and artwork offers durability, strength, and the potential for large-scale installations. Artists can shape, weld, and manipulate steel billets to create a wide range of sculptures, from abstract forms to figurative representations. The industrial aesthetic of steel can also add a contemporary and bold element to the artwork. Additionally, steel can be finished with various techniques such as painting, patina, or polishing, allowing artists to further enhance their creative vision. Overall, steel billets present an exciting opportunity for artists to explore and push the boundaries of their artistic expression.

- Q: How are steel billets cooled after the manufacturing process?

- Steel billets are typically cooled after the manufacturing process using methods such as air cooling, water quenching, or accelerated cooling techniques.

Send your message to us

New technology converter continuous casting square steel billet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 800000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords