New Products-Auto-climbing Protection Panel1

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

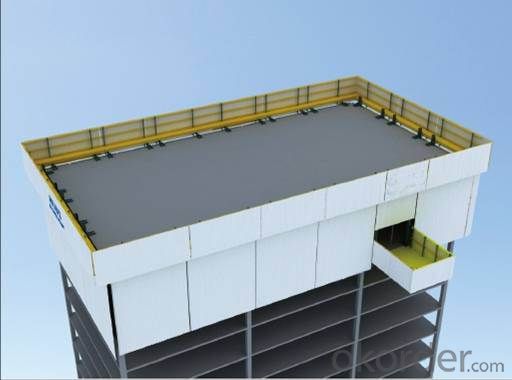

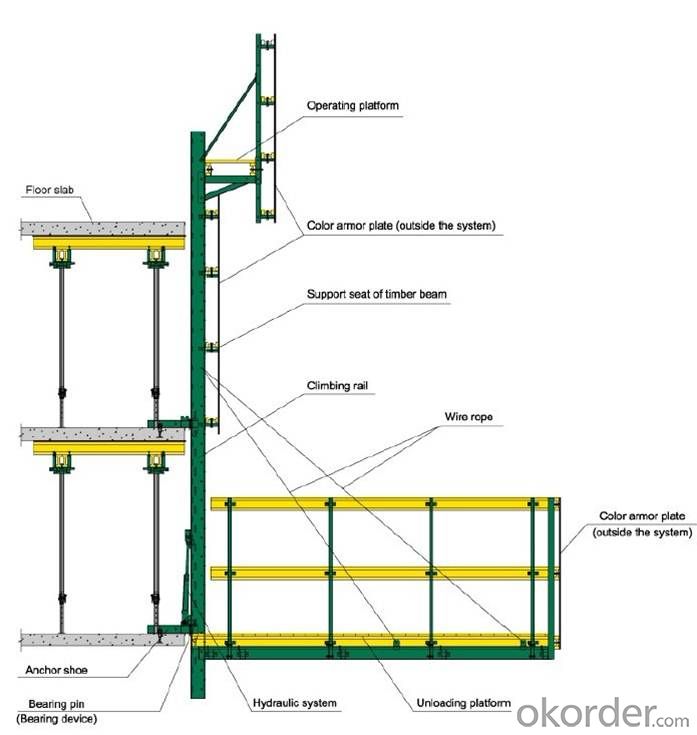

The climbing protection panel isenclosure for construction of

high-rise buildings.The system has hydraulic system as its

power, so it can climb up byitself. Cranes are not needed

during the climbing. Thesystem can match loading platform, 、

which is convenient for movingformwork and other materials

to upper floor withoutdisassembly.The construction efficiency

will be increased highly. Theclimbing protection panel is an

advanced, modern system whichsuits the demand of safety

and civilization, widely used inconstruction.

- Q: How do you transport steel props safely?

- To transport steel props safely, it is important to follow a few guidelines. Firstly, ensure that the props are securely fastened and stacked in a stable manner to prevent any movement during transportation. Use appropriate lifting equipment, such as cranes or forklifts, to load and unload the props carefully. It is also recommended to use protective coverings or padding to prevent any scratching or damage. Lastly, adhere to the weight limits and regulations specified by the transportation authorities to ensure a safe and legal transport of steel props.

- Q: What are the typical diameters of steel props?

- The typical diameters of steel props range from 40mm to 60mm, depending on the specific requirements of the construction project.

- Q: Can steel props be used to support walls during demolition?

- Yes, steel props can be used to support walls during demolition. Steel props, also known as adjustable steel acrow props, are commonly used in construction and demolition projects to provide temporary support to walls, ceilings, and other structures. They are designed to withstand heavy loads and can be adjusted to the desired height and length to provide stability and prevent collapsing during demolition. Steel props are especially useful when demolishing load-bearing walls, as they can effectively distribute the weight and ensure the safety of the surrounding structures. Additionally, steel props are easy to install and remove, making them a versatile and cost-effective solution for supporting walls during demolition.

- Q: Can steel props be used in residential construction projects?

- Yes, steel props can be used in residential construction projects. Steel props, also known as adjustable steel props or steel shores, are temporary supports used to provide vertical support to structures during construction or renovation. They are commonly used in residential construction projects to support beams, walls, and other load-bearing elements. Steel props are preferred in construction due to their strength and adjustability. They can be easily adjusted to the required height and provide stable support to heavy loads. They are typically made of high-quality steel, which ensures their durability and ability to withstand heavy loads. In residential construction projects, steel props can be used in various scenarios. For example, they can be used to support temporary beams during the installation of new windows or doors, to provide additional support to walls during demolition or renovation, or to support the weight of a temporary roof structure during the construction of a new floor. Furthermore, steel props are versatile and can be easily adjusted to fit different heights and angles, making them suitable for various applications in residential construction. They can be quickly installed and removed, saving time and effort in construction projects. However, it is important to note that the use of steel props should be done by professionals who have the necessary knowledge and experience to ensure their safe and proper installation. Improper use of steel props can lead to accidents or structural failures, which can be dangerous and costly. In summary, steel props can be effectively used in residential construction projects to provide temporary support to structures. Their strength, adjustability, and versatility make them a reliable choice for supporting various load-bearing elements. However, it is crucial to ensure that they are installed correctly by qualified professionals to ensure safety and avoid any potential risks.

- Q: Are steel props adjustable in both tension and torsion?

- Steel props are usually adjustable in tension but not in torsion. They are commonly employed in construction to bear vertical loads and offer temporary support for structures. These props can be lengthened or shortened to fit varying heights and can be secured firmly to ensure stability and prevent any potential movement or collapse. Nevertheless, steel props are not specifically engineered to endure or adapt to torsional loads, which refer to the twisting or rotational force exerted on an object. Torsional loads are typically addressed by incorporating other structural elements, like beams or columns, that are specially designed to withstand twisting forces.

- Q: Are steel props suitable for supporting temporary stages for concerts?

- Yes, steel props are suitable for supporting temporary stages for concerts. Steel props are strong, durable, and can provide the necessary stability and support required for a temporary stage setup. They can bear the weight of heavy equipment, lighting rigs, and performers, ensuring a safe and secure platform for concerts.

- Q: How do you protect steel props from extreme weather conditions?

- To protect steel props from extreme weather conditions, it is essential to apply a protective coating or paint on the surface of the steel. This coating acts as a barrier, preventing direct contact between the steel and the elements. Additionally, regular maintenance and inspections should be conducted to identify any signs of corrosion or damage, allowing for prompt repairs and ensuring the ongoing protection of the steel props.

- Q: What is the pre - steel brace

- When it comes to brace generally refers to Rachel steel purlin, it is reinforced, but also to enhance the stability of the purlin purlin, not easy to lose in the external force under certain failure. Section purlin are generally H steel, C shape, Z shape, is reducing cabin panel span and fixed roof panel.The main specifications of steel support are Phi 400, Phi 580, phi, phi, phi, phi, phi, phi, and so on, and so on, and so on, and so on, and so on, and so on, and so on, and so on, and so on, and so on, and so on.

- Q: Subway construction of steel support needs qualification

- But in general, because many such systems in order to cooperate with the construction of the environment, may also have existing ground sections, so usually covers the metropolitan area of all underground and on the ground of the high density transportation system.

- Q: How do you ensure stability on uneven or sloped surfaces when using steel props?

- To ensure stability on uneven or sloped surfaces when using steel props, it is important to use adjustable props with a base plate or foot plate. These plates provide a larger surface area for distribution of weight and help to prevent sinking or tipping. Additionally, adjusting the prop to the desired height and securing it tightly ensures a stable and secure foundation.

Send your message to us

New Products-Auto-climbing Protection Panel1

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches