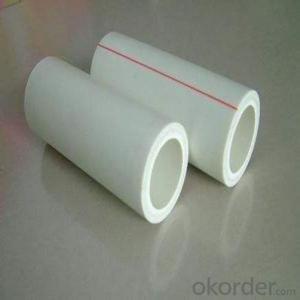

Durable Industrial Plastic Tubes - New PPR Pipe with Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

The comprehensive technical performance and economic indicator of PP-R are much better than galvanized pipe, UPVC pipe, polyethylene-aluminum compound pipe, PE-X (cross-linked polyethylene) and polybutylene pipe etc. For this reason PP-R is the leading products and widely used for feed-water piping in developed countries in Europe and America.

German Standard DIN8077 and DIN8078.

Nowadays PPR pipes win more attention and have been used all over the whole world more widely with its excellent sanitization performance, high heat resistance, compression resistance, corrosion resistance, pliability and seismic performance which make PP-R the real environmental friendly pipe.

Application:

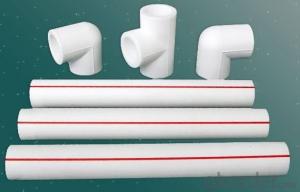

1) Cold and hot water systems of residence and commercial buildings

2) Transportation of industrial water supply and chemical materials

3) Pure water pipe system

4) Transportation system of drinking water production

5) Piping networks for solar plants

Our Services:

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T,D/A,D/P, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Product Description:

Pressure | Size(mm) | Pressure | Size(mm) |

PN1.25MPA | 20*2.0 |

PN1.6MPA | 20*2.3 |

25*2.3 | 25*2.8 | ||

32*2.9 | 32*3.6 | ||

40*3.7 | 40*4.5 | ||

50*4.6 | 50*5.6 | ||

63*5.8 | 63*7.1 | ||

75*6.8 | 75*8.4 | ||

90*8.2 | 90*10.1 |

Product Show:

FAQ

Q:Can I get some samples?

A:Yes.Sample order welcomed.

Q:What is the payment term?

A:T/T,L/C at sight.

Q:May I visit your factory?

A:Sure,wlcome any time .We can also pick you up at airport and station.

- Q: Are plastic tubes suitable for medical device manufacturing?

- Yes, plastic tubes are suitable for medical device manufacturing. They are commonly used in various medical applications such as catheters, IV lines, and respiratory tubes due to their flexibility, durability, and compatibility with sterilization processes. Plastic tubes can be customized to meet specific requirements and are cost-effective compared to other materials. Additionally, they offer excellent biocompatibility and can be manufactured to be resistant to chemicals and bacteria, ensuring patient safety.

- Q: What are the advantages of using plastic tubes in the automotive packaging industry?

- The advantages of using plastic tubes in the automotive packaging industry include durability, flexibility, and cost-effectiveness. Plastic tubes can withstand harsh handling during transportation and protect automotive components from damage, ensuring their safe delivery. Their flexibility allows for easy customization, enabling manufacturers to design packaging solutions that fit various sizes and shapes of automotive parts. Additionally, plastic tubes are lightweight and require less material, making them a cost-effective option for packaging in the automotive industry.

- Q: and waist, torso of your body, reason why is because i need these materials for building, making a costume for cosplaying, and i'm looking for it in plastic instead of meta

- I'm not sure if these are the best solution for you, but... something to consider, at least? Best of luck with your cosplay, in any case! (Is it strange that I'm now really curious what your costume will be? All this tube research has me interested. :y )

- Q: Can plastic tubes be used for storing personal care products?

- Yes, plastic tubes can be used for storing personal care products as they are commonly used in the cosmetics and personal care industry for packaging items such as creams, lotions, gels, and serums. Plastic tubes provide convenience, ease of use, and are often designed to be portable and hygienic.

- Q: What are the common uses for plastic tubes in construction?

- Plastic tubes are commonly used in construction for various purposes such as plumbing, electrical wiring, and ventilation systems. They are also utilized for underground utilities like water supply and drainage systems. Additionally, plastic tubes are used for structural support in concrete formwork and as conduits for cables and wires.

- Q: What is the level of rigidity of plastic tubes?

- The level of rigidity of plastic tubes can vary depending on the specific type of plastic used, but generally, plastic tubes are known for their flexibility and ability to bend without breaking.

- Q: What are the requirements for the installation of expansion joints for drainage plastic pipes?

- No design requirements, pipeline more than 2 meters should be set expansion joints, expansion joints shall not exceed the maximum distance of 4 meters. Installed in a vertical pipe, height less than 4 meters, each layer should be set up, the height greater than 4 meters, according to the pipe design expansion amount and the maximum allowable elongation to determine the expansion joint.

- Q: Can plastic tubes be used for packaging personal care products?

- Yes, plastic tubes can be used for packaging personal care products.

- Q: What are the different wall thickness options for plastic tubes?

- The different wall thickness options for plastic tubes vary depending on the specific application and requirements. Generally, plastic tubes can have wall thicknesses ranging from thin (around 0.5 mm or less) to medium (around 1-2 mm) and thick (over 2 mm). The choice of wall thickness depends on factors such as the desired strength, flexibility, and cost-effectiveness for the intended use of the plastic tube.

- Q: How do you label plastic tubes?

- Plastic tubes can be labeled using various methods such as adhesive labels, heat shrink sleeves, direct printing, or using markers and tape. The choice of labeling method depends on the type of plastic, intended use, and desired durability of the label.

Send your message to us

Durable Industrial Plastic Tubes - New PPR Pipe with Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords