Tru Timber Mirror Aluminum Coil/Strip for Lighting Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mirror Aluminum Coil/Strip for Lighting Decoration

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3A21 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum or paper |

7) Coil Inner diameter | 75mm, 150mm, 200mm, 300mm, 405mm, 505mm or as required |

8) Protective film can be added

2. Application of Mirror Aluminum Coil/Strip for Lighting Decoration

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mirror Aluminum Coil/Strip for Lighting Decoration

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

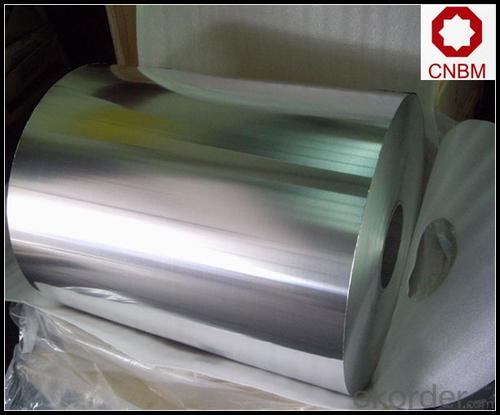

5. Image of Mirror Aluminum Coil/Strip for Lighting Decoration

6. Package and shipping of Mirror Aluminum Coil/Strip for Lighting Decoration

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the potential applications of coil-perforated aluminum coils?

- Coil-perforated aluminum coils have a wide range of potential applications due to their unique properties. They can be used in architectural and construction projects for decorative facades, sunscreens, and acoustic panels. Additionally, they find use in automotive manufacturing for radiator grilles and soundproofing components. The coils are also suitable for air filtration systems, HVAC equipment, and industrial machinery, thanks to their excellent airflow and heat dissipation capabilities. Overall, the potential applications of coil-perforated aluminum coils are extensive, offering versatility and functionality in various industries.

- Q: Is it possible to use aluminum coils for decorative purposes in a garden setting?

- <p>Yes, aluminum coils can be used for decoration in the garden. They are lightweight, durable, and resistant to corrosion, making them suitable for outdoor use. You can form them into various shapes or use them to create unique garden structures such as trellises, sculptures, or even as part of a fence. Their metallic finish can add a modern or industrial touch to your garden's aesthetic, and they can be painted or left in their natural state to blend with different garden themes.</p>

- Q: Can aluminum coils be used in aerospace applications?

- Indeed, aerospace applications do make use of aluminum coils. The aerospace industry extensively utilizes aluminum due to its lightweight nature and impressive strength-to-weight ratio. Aircraft structures, including fuselages, wings, and landing gear, often incorporate aluminum coils. Moreover, heat transfer and cooling systems also benefit from their presence. The exceptional corrosion resistance and high thermal conductivity of aluminum coils render them fitting for diverse aerospace purposes. Furthermore, their malleability and ease of fabrication enable the creation of intricate shapes and designs necessary for aerospace components.

- Q: What is the balanced equation for copper (I) oxide and Aluminum?

- Copper(I) oxide is a solid and so is aluminum. Any reaction that might occur would have to be at an elevated temperature. This is a thermite reaction in which copper(I) is reduced to copper metal (molten) and aluminum is oxidized to aluminum oxide. 3Cu2O(s) + 2Al(s) -- 6Cu(s) + Al2O3(s) ========= Follow up ========== Do you mean in aqueous solution? There won't be any copper(I) chloride in aqueous solution. CuCl is very insoluble in water, but will undergo disproportionation to form Cu2+ ions and copper metal. Therefore, you would actually have a solution of copper(II) chloride. Copper(II) chloride will react with aluminum to form copper metal and aluminum ions. Ordinarily aluminum won't react with copper(II) ions. The reaction does proceed in the presence of chloride ion. This is because the chloride ion will react with the Al2O3 layer on the surface of aluminum metal to make [AlCl4]^- which exposes the aluminum metal below, and thus a reaction can occur. 3Cu2+ + 2Al(s) -- 2Al3+ + 3Cu(s)

- Q: Are there any limitations on the anodizing of aluminum coils?

- Yes, there are certain limitations on the anodizing of aluminum coils. Some of the limitations include the size and thickness of the coils, as well as the surface finish and quality of the aluminum. Additionally, the composition and alloy of the aluminum can also affect the anodizing process. It is important to consider these limitations to ensure successful and satisfactory anodizing results.

- Q: What are the different types of alloys used for aluminum coils?

- There are several different types of alloys that are commonly used for aluminum coils. The most commonly used alloy for aluminum coils is 3003. This alloy is known for its excellent corrosion resistance and moderate strength. It is often used in applications where high strength is not required, such as in roofing and siding. Another commonly used alloy for aluminum coils is 5052. This alloy has good weldability and formability, making it suitable for a wide range of applications. It is often used in the automotive industry for body panels and fuel tanks. 6061 is another popular alloy for aluminum coils. This alloy has excellent strength and is often used in structural applications. It is commonly used in the aerospace industry for aircraft parts and in the construction industry for structural components. Other alloys that are used for aluminum coils include 1100, 5005, and 8011. Each of these alloys has its own unique properties and characteristics, making them suitable for different applications. For example, 1100 is known for its high electrical conductivity and is often used in electrical applications, while 8011 is commonly used for packaging and food containers due to its excellent corrosion resistance. In summary, the different types of alloys used for aluminum coils include 3003, 5052, 6061, 1100, 5005, and 8011. These alloys offer a range of properties and characteristics that make them suitable for various applications across industries such as automotive, aerospace, construction, and packaging.

- Q: Can aluminum coils be painted or coated for aesthetic purposes?

- Aluminum coils have the potential to be painted or coated in order to enhance their visual appeal. The versatility of aluminum makes it a suitable material for easy painting or coating, resulting in an improved appearance. This process offers a multitude of color choices and finishes, allowing for personalization and attractiveness in numerous applications. Furthermore, the paint or coating serves as a safeguard against corrosion and weather damage, thereby prolonging the lifespan and durability of the aluminum coils. Nevertheless, it is crucial to select the appropriate paint or coating that is compatible with aluminum and appropriate for the intended purpose to achieve the best outcome.

- Q: This question asks about the environmental impact of aluminum coils, which are commonly used in various industries.

- <p>Aluminum coils have both positive and negative environmental impacts. On the positive side, aluminum is highly recyclable, and its use in coils reduces the need for raw material extraction, thus conserving natural resources. The recycling process also consumes less energy compared to primary aluminum production, reducing greenhouse gas emissions. However, the production of aluminum coils involves energy-intensive processes that can contribute to carbon emissions. Additionally, if not properly managed, the waste from aluminum production can pollute water bodies and soil. Overall, the environmental impact depends on the balance between recycling and production practices, as well as waste management.</p>

- Q: What are the weight considerations when using aluminum coils?

- When using aluminum coils, there are several weight considerations to take into account. Firstly, aluminum coils are generally lighter in weight compared to other metals, such as steel. This makes them a popular choice in industries where weight reduction is a priority, such as automotive manufacturing or aerospace applications. The lightweight nature of aluminum coils allows for improved fuel efficiency in vehicles and increased payload capacity in airplanes. Secondly, the weight of the aluminum coil itself is important to consider. Depending on the specific application, the weight of the coil may need to be within certain limits to ensure proper functioning and structural integrity. For example, in HVAC systems, the weight of the aluminum coil needs to be suitable for the unit to be mounted securely and able to withstand vibrations or pressure changes. Additionally, the weight of the aluminum coil can impact transportation and installation. Lighter coils are easier to handle, transport, and install, reducing the time and effort required for these processes. This can be particularly advantageous in construction projects where large quantities of aluminum coils are used. It is also crucial to consider the weight-bearing capacity of the structures or equipment that will be supporting or utilizing the aluminum coils. The weight of the coils, combined with any additional components or materials, should not exceed the load capacity of the system to avoid structural failure or safety hazards. Lastly, the weight of aluminum coils can affect cost considerations. Since aluminum is typically priced based on weight, lighter coils may be more cost-effective compared to heavier alternatives. However, it is important to strike a balance between weight reduction and meeting the required performance and strength specifications. In conclusion, weight considerations when using aluminum coils encompass factors such as the overall weight reduction benefits, the weight of the coil itself, transportation and installation ease, load-bearing capacity, and cost implications. Taking these considerations into account ensures the successful and efficient utilization of aluminum coils in various industries and applications.

- Q: Can aluminum coils be used in wastewater treatment plants?

- Yes, aluminum coils can be used in wastewater treatment plants. Aluminum coils are commonly used in heat exchangers within wastewater treatment plants to transfer heat effectively and efficiently. They are resistant to corrosion and can withstand the harsh environment of wastewater treatment processes.

Send your message to us

Tru Timber Mirror Aluminum Coil/Strip for Lighting Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords