Mill Finished Directed Rolled Aluminum Strip AA3004 - Aluminum Sheets for Sale Mercer County

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Mill Finished Hot Rolled Aluminium Strip is one semi-finished aluminium material.For the Alloy AA3004 is widly used in beer cans industry. Its weight is much lower than steel. Moreover, aluminium material can be anti-rust and re-cycle during the industry process. So aluminium have instead of steel in the beer can industry.

2. Main features of the product

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

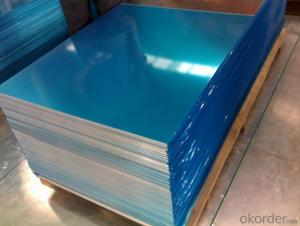

3. Image:

4.Products Specification

| Alloy | Thickness | Coil ID | Coil Weight | Main Usage |

| AA5052 | 0.2mm-3mm | 508mm+/-10mm | 2-2.5 tons | Ships |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Is it possible to substitute traditional wooden windows and doors with aluminum sheets?

- <p>Yes, you can use aluminum sheets to replace traditional wooden windows and doors. Aluminum is a popular choice due to its durability, low maintenance, and resistance to weather and pests. It also offers good thermal performance and can be designed to mimic the appearance of wood. However, it's important to consider factors like insulation, cost, and the specific design requirements of your project before making the switch.</p>

- Q: Are aluminum sheets suitable for furniture manufacturing?

- Indeed, furniture manufacturing can make effective use of aluminum sheets. Aluminum, being a lightweight and versatile material, offers a multitude of advantages for the production of furniture. It possesses corrosion resistance, rendering it suitable for both indoor and outdoor furniture. Moreover, aluminum showcases a remarkable strength-to-weight ratio, facilitating the creation of robust and long-lasting furniture items. Additionally, aluminum proves to be easily malleable, as it can be cut, bent, and welded into various shapes and designs. Furthermore, aluminum can be treated with a diverse range of coatings or paints to enhance its visual appeal and safeguard it from damage. In summary, the strength, versatility, and aesthetic allure of aluminum sheets establish them as a viable alternative for furniture manufacturing.

- Q: which has more volume? a kg of gold or a kg of aluminum? please explain in physics terms

- Think of it this way: Which metal is lighter? How do you know this? Because a given volume of gold weighs more than a given volume of aluminum. So which one has more volume? A kg of aluminum.

- Q: i need to know these things please....can aluminium withstand the forces of being in a cargo hold on a air freight, can it withstand extreme temps and to what extent an is it microwavable?? please help me

- No metals are microwavable, they will ruin any microwave oven by producing sparks. Even ceramic plates with a little metallic paint eg of silver will spark. Aluminium on its own has little strength but when mixed with small amounts of eg copper or manganese it aquires great strength while remaining light. In addition it has the advantage of being very resistant to oxidation and corrosion. It is certainly used extensively in aircraft construction. Due to being non toxic it used to make cans for beers, soft drinks (sodas) etc However it doesn't stand up well to high temperatures, its melting point is just at 660 degrees celsius, by comparison for iron it is 1540 and tungsten 3420.

- Q: What specific considerations should be taken into account when using aluminum sheets in cold weather conditions?

- <p>In cold climates, aluminum sheets should be selected with consideration for their thermal expansion properties. It's important to use alloys with low thermal expansion coefficients to minimize distortion. Additionally, the design should account for potential contraction and expansion to prevent warping or cracking. Proper insulation and sealing are crucial to prevent condensation and moisture buildup, which can lead to corrosion. It's also advisable to use thicker sheets to enhance durability and resistance to the elements. Regular inspections and maintenance are recommended to ensure the longevity of aluminum structures in cold environments.</p>

- Q: What are the standard tolerances for aluminum sheets?

- The standard tolerances for aluminum sheets can vary depending on the specific application and industry requirements. However, common tolerances for thickness range from +/- 0.005 to +/- 0.015 inches, while dimensions may have tolerances in the range of +/- 0.030 to +/- 0.125 inches. It is important to consult the appropriate industry standards or specifications for precise tolerances based on the specific needs of the project.

- Q: What are the different methods of polishing aluminum sheets?

- Polishing aluminum sheets can be done through various methods, each with its own pros and cons. Here are some commonly used techniques: 1. Manual polishing: By employing sandpaper or abrasive pads, one can manually rub the surface of the aluminum sheet to achieve a high level of shine and smoothness. However, this method demands physical effort and can be time-consuming, especially for larger sheets. Careful execution is crucial to avoid leaving behind scratches or marks. 2. Chemical polishing: Dissolving a thin layer of the aluminum surface using chemical compounds can result in a smoother and shinier finish. This method is suitable for larger sheets or complex shapes where manual polishing is impractical. However, chemical handling must be meticulous, and it may not be suitable for certain aluminum alloys. 3. Electropolishing: An electrochemical process involving the use of an electric current to remove a thin layer of material from the aluminum surface. This method guarantees a smooth and shiny finish for both small and large sheets. It is particularly effective in eliminating surface imperfections and achieving a uniform appearance. However, specialized equipment and expertise are required to properly control the process. 4. Vibratory finishing: Placing aluminum sheets in a vibratory machine with abrasive media, like ceramic or plastic chips, can help remove surface imperfections and achieve a polished finish. This method is ideal for large batches of sheets and can be cost-effective. Nevertheless, it may not produce the same level of shine as other methods. 5. Buffing and polishing compounds: These compounds are applied to the aluminum sheets and then buffed using a rotary tool or polishing machine. The abrasive particles in the compounds aid in removing scratches and enhancing the metal's shine. This method is relatively quick and easy, but it may not be as effective for significant oxidation or deep scratches. Ultimately, the choice of polishing method depends on factors such as the size and type of the aluminum sheets, desired level of shine, and available equipment and expertise. It is advisable to test different methods on a small area before proceeding with the full polishing process to ensure satisfactory results.

- Q: I want to make a dress from aluminum cans. However, aluminum is very sharp once cut. So, do you thing there is a possible way to make the cut edges less sharp? Would sanding the edges help?

- Or you could just curve them to the back or front a bit by hand, or roll them over a dowel, etc, for more of a curve but maybe easier to do. You could also try sanding or filing them (electric sanders/etc would be best but wear eye protection and a mask to keep metal dust/bits from getting to you). Or you could also paint each edge with something like ModPodge, white glue, polyurethane, etc, all of which would dry clear (or dip each edge into a tray of one of them)...or you could use acrylic paint but that would be colored. Or you could put tape over the edge (but more time consuming). Or just connecting the cans could help, whether you'll be connecting them with lacing through holes, etc, or the edges of some glued/taped overlapped on other cans.

- Q: Are aluminum sheets suitable for use in harsh chemical environments?

- Aluminum sheets are indeed suitable for usage in harsh chemical environments. Their remarkable resistance to numerous chemicals, including acids, alkalis, and organic solvents, is noteworthy. The formation of a protective oxide layer on the surface of aluminum aids in preventing corrosion. Moreover, aluminum's lightweight nature, durability, and cost-effectiveness have contributed to its widespread use in various industrial applications within harsh chemical environments. Nevertheless, it is essential to acknowledge that the appropriateness of aluminum sheets in particular chemical environments may also be influenced by factors such as temperature, concentration, and duration of exposure to the chemicals. To ensure the proper selection of materials for a given chemical environment, it is always advisable to consult experts or refer to specific chemical compatibility charts.

- Q: Can aluminum sheets be laminated with other materials?

- Yes, aluminum sheets can be laminated with other materials. Lamination involves bonding different layers together to create a composite material with enhanced properties and functionality. Aluminum sheets can be laminated with various materials such as polymers, fabrics, or other metals to improve their strength, durability, insulation, or aesthetic appearance. This process allows for the customization and optimization of aluminum sheets for specific applications.

Send your message to us

Mill Finished Directed Rolled Aluminum Strip AA3004 - Aluminum Sheets for Sale Mercer County

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords