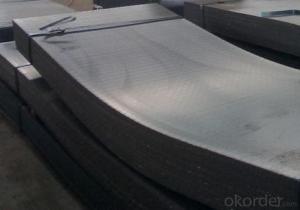

Mild Carbon Steel Sheets 20G CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Grade: | 300 Series | Standard: | JIS, AISI, ASTM, DIN, EN | Length: | 1000-6000 |

| Thickness: | 0.5-100mm | Width: | 1000-2000 | ) | |

| Brand Name: | putan | Model Number: | Q235.Q345 | Type: | Plate |

| Application: | Construction plate,boiler plate,container plate,shipbuilding plate,all | Certification: | BV | type: | plate |

Packaging & Delivery

| Packaging Details: | Export standard package,bundled or be required. The inner size of container is below: 20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high) 25tons about 24-26CBM 40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) 25tons about 54CBM 40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) 25tons about 68CBM |

| Delivery Detail: | 7-15 days after receiving the deposit |

Specifications

Q235 Carbon sheet

Original :China

thickness 0.5mm~100mm,

coil steel Processing.

MOQ : 25TON

Carbon Steel plate

Product | SS400 carbon steel plate price |

Standard |

GB/T700-2006,ASTMA283/A283M-03,ASTMA572/A572M,JISG3101-2004,SS400, JIS G3135-1986,SPEC590,EN10025/2-2004,S235JR or S235J2,E335 or S335JR…

|

Width | 500-2000mm |

WT | 0.5 –60mm |

length | 2000—6000mm |

Applications range |

Construction plate,boiler plate,container plate,shipbuilding plate,all kinds of industries and manufacturing structural applications.

|

MOQ | 25 ton / according to customers' requirement |

Quality | good attestation of honour choosed by customers SGS |

Supply capability | 5,000 ton / month |

Key to success | advanced technique and service and low price |

Authentification | ISO9001:2008 |

Market | North/South America, Europe, Asia,Africa,Mid East,ect. |

Packaging |

Standard seaworthy packing / according to the customers’requirement

|

Port | |

Delivery term |

T/T,L/C 30% deposit the balance before shipment,the balance paid by the copy of B/L OR L/C at sight

|

Delivery time | In 15 – 45 days after contract |

- Q: What are the different quality standards for steel sheets?

- There are several different quality standards for steel sheets, which are used to ensure that the material meets specific requirements and is suitable for its intended use. Some of the most common quality standards for steel sheets include: 1. ASTM A36/A36M: This standard specifies the requirements for carbon structural steel, including steel sheets, used in general structural purposes. It outlines the chemical composition, mechanical properties, and other relevant factors. 2. ASTM A568/A568M: This standard covers the general requirements for steel sheet products, including hot-rolled, cold-rolled, and coated sheets. It provides specifications for dimensions, tolerances, and surface quality. 3. EN 10130: This European standard specifies the requirements for cold-rolled low carbon steel flat products, including steel sheets. It outlines the chemical composition, mechanical properties, and other relevant factors. 4. JIS G 3302: This Japanese industrial standard covers the requirements for hot-dip zinc-coated steel sheets and coils. It includes specifications for the coating weight, surface finish, and mechanical properties. 5. ISO 3574: This international standard specifies the requirements for cold-reduced carbon steel sheet of commercial and drawing qualities. It provides guidelines for dimensions, tolerances, and mechanical properties. 6. GB/T 2518: This Chinese national standard outlines the requirements for continuous hot-dip zinc-coated steel sheets and coils. It includes specifications for the coating weight, surface finish, and mechanical properties. These quality standards help ensure that steel sheets are produced and supplied with consistent properties and characteristics, making them suitable for various applications such as construction, automotive, manufacturing, and more. It is important for manufacturers, suppliers, and end-users to adhere to these standards to ensure the quality and reliability of steel sheet products.

- Q: What is the difference between a brushed and polished steel sheet?

- A brushed steel sheet and a polished steel sheet differ in terms of their surface finishes. A brushed steel sheet is characterized by a pattern of parallel lines or scratches on its surface, created using abrasive materials or tools. The purpose of brushing is to give the steel sheet a textured appearance, which helps to hide fingerprints, scratches, and wear over time. It also provides a more industrial, matte finish. On the other hand, a polished steel sheet has a smooth and glossy surface. Polishing involves using polishing compounds or abrasive materials to remove imperfections, scratches, and oxidation from the steel surface. This process creates a reflective and mirror-like finish, enhancing the aesthetic appeal of the steel sheet. Polished steel sheets are commonly used in applications where appearance and visual appeal are important, such as architectural design, interior decoration, and high-end products. In summary, the main difference between a brushed and polished steel sheet lies in their surface finishes. Brushed steel sheets have a textured, matte appearance, while polished steel sheets have a smooth and glossy, mirror-like finish. The choice between the two depends on the desired aesthetic, functional requirements, and the intended application of the steel sheet.

- Q: What are the advantages of using steel sheets in construction?

- There are several advantages of using steel sheets in construction. Firstly, steel sheets offer excellent strength and durability, making them ideal for supporting heavy loads and withstanding extreme weather conditions. Additionally, steel sheets are highly resistant to fire, corrosion, and pests, ensuring the longevity of the structure. Furthermore, steel sheets are flexible and can be easily customized and fabricated to fit various architectural designs. Lastly, steel sheets are eco-friendly as they can be recycled, reducing waste and promoting sustainability in the construction industry.

- Q: Are steel sheets susceptible to warping or bowing?

- Yes, steel sheets are susceptible to warping or bowing due to factors such as temperature changes, uneven cooling, or excessive stress.

- Q: What is the average lifespan of steel sheets used for roofing?

- The average lifespan of steel sheets used for roofing can vary depending on several factors such as the quality of the steel, the thickness of the sheets, the climate conditions, and proper maintenance. However, on average, steel sheets used for roofing can last anywhere from 30 to 50 years or more with proper installation and regular upkeep.

- Q: What is the typical weather resistance of a steel sheet?

- The typical weather resistance of a steel sheet is quite high. Steel sheets are known for their durability and ability to withstand various weather conditions, including rain, snow, wind, and even extreme temperatures. However, the exact level of weather resistance can vary depending on factors such as the type of steel, the thickness of the sheet, and the presence of any protective coatings.

- Q: How are steel sheets protected during storage and handling?

- To safeguard steel sheets and guarantee their quality, a range of methods are employed during storage and handling. A frequently utilized technique involves applying a protective coating or oil to shield the sheets from moisture and other environmental factors that may lead to corrosion or rust. To shield steel sheets from direct sunlight, rain, and adverse weather conditions, they are frequently stored in covered warehouses or designated storage areas. This precautionary measure prevents any potential harm to the sheets and preserves their structural integrity. For transportation and handling, cranes or forklifts equipped with suitable lifting apparatus are commonly used to lift the steel sheets, minimizing the risk of bending or twisting. Moreover, the sheets are meticulously secured and stacked in a manner that reduces the likelihood of damage or deformation. Furthermore, steel sheets are often packaged with materials like plastic or cardboard to provide additional protection against scratches and physical harm. They may also be wrapped or sealed to prevent contact with moisture or contaminants. Overall, the objective is to maintain the quality of steel sheets and prevent any potential damage that could compromise their performance in future applications by ensuring they are stored and handled in a secure and controlled environment.

- Q: Are steel sheets suitable for modular construction?

- Yes, steel sheets are highly suitable for modular construction. Steel is known for its strength, durability, and versatility, making it an ideal material for constructing modular buildings. Steel sheets can be easily fabricated and assembled into various modular components, ensuring precision and accuracy in the construction process. Additionally, steel provides excellent structural integrity, resistance to fire, and is highly resistant to environmental factors such as moisture and pests. These qualities make steel sheets an excellent choice for modular construction projects.

- Q: Do steel sheets require any special storage or handling?

- Yes, steel sheets require special storage and handling to ensure their integrity and avoid any damage. They should be stored in a clean, dry, and well-ventilated area to prevent corrosion. Additionally, they should be stacked in a way that prevents distortion or bending. When handling steel sheets, it is important to use proper lifting equipment and techniques to prevent accidents and maintain the quality of the sheets.

- Q: Are the steel sheets corrosion-resistant?

- Depending on the steel type and the applied protective coating, steel sheets can exhibit corrosion resistance. Stainless steel sheets, for instance, possess outstanding corrosion resistance due to the presence of chromium, forming a passive protective layer on the surface. Furthermore, galvanized steel sheets are coated with zinc, serving as a sacrificial barrier to safeguard the underlying steel against corrosion. Coatings like painting, powder coating, or plating can also render other types of steel sheets corrosion-resistant. Thus, it becomes crucial to consider the specific steel type and any additional protective measures implemented in order to assess the corrosion resistance of steel sheets.

Send your message to us

Mild Carbon Steel Sheets 20G CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords