Microcrystalline Glass-6

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 0 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

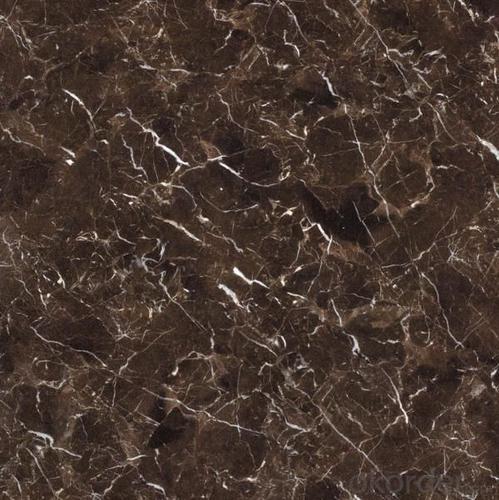

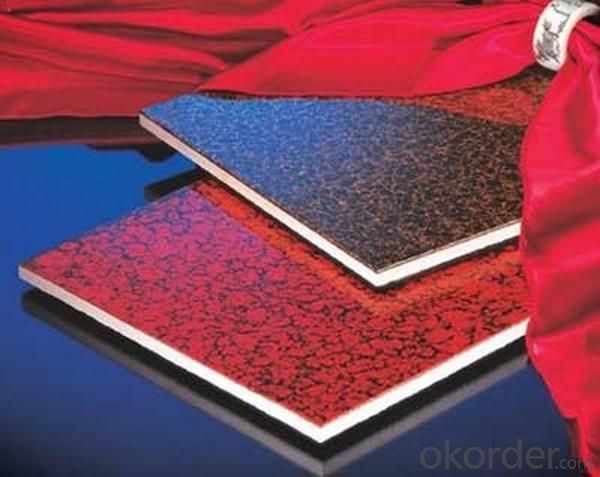

Microcrystalline Glass(Glass-ceramics) are polycrystalline material produced through controlled crystallization of base glass.

- Q: What role does zircon sand play in the production of glass? Is it a raw material for glass or a production process?

- Zircon sand is the most important zirconium containing mineral, which has the widest distribution, largest reserves and most types in zirconium minerals. It is a kind of mineral with zirconium silicate as the main component. Zircon sand is the main raw material for preparing zirconium, hafnium and many kinds of zirconium products. It has the characteristics of high melting point, low thermal conductivity and small coefficient of linear expansion. It is widely used in metallurgy, casting and other industries.Zircon sand (Gao Yingshi) is highly resistant to heat and has a melting point of 2750. Acid corrosion resistance. 80% of the world's direct use in the foundry industry, ceramics, glass industry, and the manufacture of refractory materials. A small amount used in ferrous alloys, pharmaceuticals, paints, tanning, abrasives, chemicals, and nuclear industries. Very little is used in smelting zirconium metal.

- Q: Chemical materials and additives needed for the production of glass

- 1. Blending of raw materials. The main ingredients of float glass are: 73% of silica, 13% of sodium carbonate, 9% of calcium oxide and 4% of magnesium. The ingredients are mixed in proportion, followed by the addition of small pieces of recycled glass.2. Melting of raw materials. The prepared material passes through a mixing bin and then goes into a kiln with 5 chambers and is heated at about 1550 degrees centigrade to become a molten glass. 3. Glass forming. Molten glass flows into a tin bath and floats over molten molten tin, at a temperature of about 1000 degrees celsius. The molten glass on the tin solution forms a glass band of 3.66 meters wide and a thickness of 3mm to 19mm. Because the glass and the tin are very different in viscosity, the molten glass at the top does not mix with the molten tin below, and forms very smooth contact surfaces.4. Cooling of molten glass. When the glass band leaves the bath, the temperature is about 600 degrees Celsius, then it enters the annealing chamber or the continuous cooling kiln, and the temperature of the glass is gradually reduced to 50 degrees celsius. Thus, the glass produced by the Xu cooling method is also called annealed glass. 5, cutting and storage. After the cold, the glass passes through several stages of quality inspection, then cut into different sizes for packaging, storage, storage or transportation.Quartz sand is a hard, abrasion resistant and stable chemical silicate mineral. Its main mineral composition is SiO2, the color of quartz sandFor the white, colorless or translucent, 7 hardness, brittle cleavage, conchatus fracture, oil sheen, density 2.65, bulk density (1-2.0 = 1.6), 20-200 was 1.5, the chemical, thermal and mechanical properties have obvious anisotropy, insoluble in acid, slightly soluble in KOH solution, the melting point of 1750 DEG C.

- Q: What's the name of the transparent plastic board in the market?

- Organic glass acrylic and special processing, organic glass products, light boxes with acrylic production has good transparence, pure color, rich colors, beautiful smooth, both day and night of two kinds of effect, long service life, does not affect the use of other features, in addition, acrylic and aluminum plate material, advanced screen printing etc. can be the perfect combination, to meet the business needs of acrylic plastic is to improve the store level business, unified enterprise image of the best form of outdoor advertising.

- Q: Why is toughened glass broken?

- A ton of glass raw materials, at least 3-4 of nickel sulfide crystals, the number of tons of glass made of pieces of a square size glass, which will have 3-4 to explode, which is self depicting the image of.

- Q: What material can not be sprayed on the glass?

- 1.. First spray the glass and then stick it on the outside with a transparent adhesive tape..2. uses the special printing ink for the glass product, 3. uses the glass glue to adjust the soluble pigment and the dye toner. 4. go to the print shop and do the writing, then glue it on. I hope my answer will be of some help to you

- Q: What are the Department of mobile phone lens?

- The glass raw materials into a glass rod, glass rod processed into glass ball (a glass ball is also called the preform) - glass ball processing (Molding) - lens lens coating - coated lenses and lens group (group A, general is a mirror.)

- Q: Does the material of sunglasses choose good glass or plastic?

- Now, the most common use of sunglasses is resin lenses. The resin is a phenolic structure of chemicals, characterized by its light, high temperature resistance, impact resistance, and the ability to effectively block ultraviolet light. It should be said that this is a more excellent sunglasses, lens materials, polarized lenses made of this material will see more clearly.

- Q: Is flat glass the main material or structural component in raw materials?

- The general case is the principal. Such as doors and windows, glass, glass partition, ceiling, and so on.

- Q: As the raw material for glass wool is what

- Glass wool is a type of glass fiber, is a kind of artificial inorganic fibers. Quartz, sand, limestone, dolomite and other natural ore as the main raw materials, with a number of soda ash, borax and other chemical raw materials into glass. In the melting state, with the help of external forces, blowing system into floc fiber, fiber and fiber for the solid cross, intertwined with each other, showing a lot of small gap. This gap can be considered as a pore. Therefore, the glass wool can be regarded as a porous material and has good thermal insulation and sound absorption property.

- Q: Use of glass flake cement

- Good temperature resistance. The use of glass scale lining, its heat resistance than similar resin coating can be increased by 20-40 degrees, so often used in oil pipelines, hot water pipelines, heat resistant chemical devices.

We manufacture high-tech products, mainly including transparent glass ceramic, black ceramic glass, porcelain white glass ceramic, ceramic containers and so on. Our products are mainly applicable for electric furnaces, induction cookers, highlight cookers, electric ceramic heaters, microwave ovens, ovens, physiotherapy instruments, gas stoves, cooking utensils, fireplaces, observation windows and so on.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 1992 |

| Annual Output Value | Above US$ 100 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe |

| Company Certifications | ISO 9001:2000 ;ISO 14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Ningbo, Shanghai |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 50,000-100,000 square meters |

| No. of Production Lines | 7 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Low |

Send your message to us

Microcrystalline Glass-6

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 0 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords