Metral Scaffolding System with En12810 Standard and SGS Certified CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Metral Scaffolding System with En12810 Standard and SGS Certified

Type:

Material:

Lapping Form:

Framework:

Supporting Mode:

Erection Position:

Scaffolding Part Type:

Move Method:

Structural Style:

Surface Treatment:

Certificate:

Color:

Production Capability:

Delivery Time:

Export Markets:

Descriptions of Metral Scaffolding System with En12810 Standard and SGS Certified

1. Standard:

3000mm, 2500mm, 2000mm, 1500mm, 1000mm, 500mm.

2. Ledger:

3000mm, 2000mm, 1780mm, 1500mm, 1000mm, 500mm.

3. Diagonal brace:

3000x2000mm, 1780x2000mm, 1000x1500mm, 1000x2000mm, 1500x2000mm.

4. Tube specification:

Φ 48.3x4.0mm, φ 48.0 x3.25mm, φ 48.0 x3.0mm.

5. Surface Finish:

Hot DIP Galv. Electric Galv.Powder coating, Dip Painting.

6. Material:

Q235, Q345

7. Certificate:

EN12810,SGS test report for loading capacity.

The Parts of Metral Scaffolding System with En12810 Standard and SGS Certified

| DESCRIPTION | MATERIAL | QTY. (PCS) | W. T. (KG/PC) | SURFACE |

| 3.00m standard | Q345 48.3*3.2mm | 1.00 | 15.3 | Hot-dipped Galvanized |

| 2.50m standard | Q345 48.3*3.2mm | 1.00 | 12.9 | Hot-dipped Galvanized |

| 2.00m standard | Q345 48.3*3.2mm | 1.00 | 10.5 | Hot-dipped Galvanized |

| 1.50m standard | Q345 48.3*3.2mm | 1.00 | 8.1 | Hot-dipped Galvanized |

| 1.00m standard | Q345 48.3*3.2mm | 1.00 | 5.7 | Hot-dipped Galvanized |

| 0.50m standard | Q345 48.3*3.2mm | 1.00 | 3.3 | Hot-dipped Galvanized |

| 2.00m ledger | Q345 48.3*2.5mm | 1.00 | 6.8 | Hot-dipped Galvanized |

| 1.80m ledger | Q345 48.3*2.5mm | 1.00 | 6.2 | Hot-dipped Galvanized |

| 1.50m ledger | Q345 48.3*2.5mm | 1.00 | 5.3 | Hot-dipped Galvanized |

| 1.20m ledger | Q345 48.3*2.5mm | 1.00 | 4.4 | Hot-dipped Galvanized |

| 0.90m ledger | Q345 48.3*2.5mm | 1.00 | 3.5 | Hot-dipped Galvanized |

| 0.60m ledger | Q345 48.3*2.5mm | 1.00 | 2.6 | Hot-dipped Galvanized |

| 2.00*2.00m brace | Q235 33.5*2.3mm | 1.00 | 7 | Hot-dipped Galvanized |

| 1.80*2.00m brace | Q235 33.5*2.3mm | 1.00 | 6.7 | Hot-dipped Galvanized |

| 1.50*2.00m brace | Q235 33.5*2.3mm | 1.00 | 6.4 | Hot-dipped Galvanized |

| 1.20*2.00m brace | Q235 33.5*2.3mm | 1.00 | 6.1 | Hot-dipped Galvanized |

| 2.00*1.50m brace | Q235 33.5*2.3mm | 1.00 | 6.3 | Hot-dipped Galvanized |

| 1.80*1.50m brace | Q235 33.5*2.3mm | 1.00 | 6 | Hot-dipped Galvanized |

| 1.50*1.50m brace | Q235 33.5*2.3mm | 1.00 | 5.6 | Hot-dipped Galvanized |

| 1.20*1.50m brace | Q235 33.5*2.3mm | 1.00 | 5.2 | Hot-dipped Galvanized |

| 0.90*1.50m brace | Q235 33.5*2.3mm | 1.00 | 4.9 | Hot-dipped Galvanized |

| 0.60*1.50m brace | Q235 33.5*2.3mm | 1.00 | 4.7 | Hot-dipped Galvanized |

| 2.00*1.00m brace | Q235 33.5*2.3mm | 1.00 | 5.8 | Hot-dipped Galvanized |

| 1.80*1.00m brace | Q235 33.5*2.3mm | 1.00 | 5.4 | Hot-dipped Galvanized |

| 1.50*1.00m brace | Q235 33.5*2.3mm | 1.00 | 4.9 | Hot-dipped Galvanized |

| 1.20*1.00m brace | Q235 33.5*2.3mm | 1.00 | 4.5 | Hot-dipped Galvanized |

| 0.90*1.00m brace | Q235 33.5*2.3mm | 1.00 | 4.1 | Hot-dipped Galvanized |

| 0.60*1.00m brace | Q235 33.5*2.3mm | 1.00 | 3.8 | Hot-dipped Galvanized |

| 2.00*2.00m brace | Q345 48.3*2.5mm | 1.00 | 10.2 | Hot-dipped Galvanized |

| 1.80*2.00m brace | Q345 48.3*2.5mm | 1.00 | 9.8 | Hot-dipped Galvanized |

| 1.50*2.00m brace | Q345 48.3*2.5mm | 1.00 | 9.2 | Hot-dipped Galvanized |

| 1.20*2.00m brace | Q345 48.3*2.5mm | 1.00 | 8.8 | Hot-dipped Galvanized |

| 2.00*1.50m brace | Q345 48.3*2.5mm | 1.00 | 9.1 | Hot-dipped Galvanized |

| 1.80*1.50m brace | Q345 48.3*2.5mm | 1.00 | 8.7 | Hot-dipped Galvanized |

| 1.50*1.50m brace | Q345 48.3*2.5mm | 1.00 | 8 | Hot-dipped Galvanized |

| 1.20*1.50m brace | Q345 48.3*2.5mm | 1.00 | 7.4 | Hot-dipped Galvanized |

| 0.90*1.50m brace | Q345 48.3*2.5mm | 1.00 | 7 | Hot-dipped Galvanized |

| 0.60*1.50m brace | Q345 48.3*2.5mm | 1.00 | 6.6 | Hot-dipped Galvanized |

| 2.00*1.00m brace | Q345 48.3*2.5mm | 1.00 | 8.3 | Hot-dipped Galvanized |

| 1.80*1.00m brace | Q345 48.3*2.5mm | 1.00 | 7.7 | Hot-dipped Galvanized |

| 1.50*1.00m brace | Q345 48.3*2.5mm | 1.00 | 7 | Hot-dipped Galvanized |

| 1.20*1.00m brace | Q345 48.3*2.5mm | 1.00 | 6.2 | Hot-dipped Galvanized |

| 0.9*1m brace | Q345 48.3*2.5mm | 1.00 | 5.6 | Hot-dipped Galvanized |

| 0.6*1m brace | Q345 48.3*2.5mm | 1.00 | 5.2 | Hot-dipped Galvanized |

| 0.88m board bracket | Q345 48.3*2.5mm | 1.00 | 9.5 | Hot-dipped Galvanized |

| 0.60m base collar down | Q235 38.1*4.5mm | 1.00 | 4.4 | Hot-dipped Galvanized |

| 0.60m base collar up | Q235 38.1*4.5mm | 1.00 | 5.2 | Hot-dipped Galvanized |

| 0.24*2.00m Plank | DX51D-Z80 | 1.00 | 8.2 | Hot-dipped Galvanized |

| 0.24*1.80m Plank | DX51D-Z80 | 1.00 | 7.5 | Hot-dipped Galvanized |

| 0.24*1.50m Plank | DX51D-Z80 | 1.00 | 6.5 | Hot-dipped Galvanized |

| 0.24*1.20m Plank | DX51D-Z80 | 1.00 | 5.5 | Hot-dipped Galvanized |

| 0.24*0.90m Plank | DX51D-Z80 | 1.00 | 4.5 | Hot-dipped Galvanized |

| 0.50*2.00m Plank | DX51D-Z80 | 1.00 | 15.3 | Hot-dipped Galvanized |

| 0.50*1.80m Plank | DX51D-Z80 | 1.00 | 14 | Hot-dipped Galvanized |

| 0.50*1.50m Plank | DX51D-Z80 | 1.00 | 11.9 | Hot-dipped Galvanized |

| 0.50*1.20m Plank | DX51D-Z80 | 1.00 | 9.9 | Hot-dipped Galvanized |

| 0.50*0.90m Plank | DX51D-Z80 | 1.00 | 7.9 | Hot-dipped Galvanized |

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: Salt doesn't really make any different when cleaning infact I think it makes more dried skin to get stick on the bar. My side piercing is fine but the one closest to my eye is painful when pushed or touched I think this is because I accidentally sleep on it without realising. It's red but it has no lump around the piercing is it infected or is it just trying to heal?

- The reason why the earring will stick to the skin and dry up because you're using too much salt. Cleaning it with warm sea salt water is the best way to clean your piercing, especially soaking it in a bowl for 5-10 min. Make-up wipes have alcohol in them, which irritates piercings, just stick to salt. H2Ocean is great, it's a little pricey but it has the right salinity and other ingredients essential for healing tissues. It's not infected, it's just irritated because you slept on it. An infection will have pain, lots of swelling, dark yellowish pus, and throbbing. Give it a sea salt soak and the redness and soreness will go away.

- Q: What are the dangers of scaffolding

- Analysis of the types of scaffolding accidents1) the entire frame dumping or local collapse frame2) the whole frame instability and vertical collapse3) personnel from scaffold falling

- Q: On Wednesday day I'm planning to get this done (the top piercing). I've been thinking about it for a while now really want it.What problems can I have with this piercing?How long does it take to heal ect?Thanks =)

- i've not had scaffolding but i've got a wide range of cartilage piercings and they take about 12weeks to heal... i would just say be careful not to catch it and keep it clean. good luck :)

- Q: why scaffold need for inspected within the preceding 7 days and after adverse weather condition?

- It is a work safety issue. Past experience has shown that scaffolding sometimes gets modified by unqualified people (or weather) resulting in injury or death.

- Q: Are the terms quot;nuclear matrixquot; and quot;nuclear scaffoldquot; interchangeable? I know that when we talk about DNA compaction we say that MARs on the DNA attach to the nuclear scaffold. I am wondering if the scaffold is just a specific part of the matrix??

- For most purposes, they are interchangeable terms for the same things. Some people favor one term, some the other. The ones who favor matrix over scaffold or vice versa may have some argument as to why it is better or a difference but in general people use them interchangeably.

- Q: How to calculate the vertical force of scaffolding

- First, the calculation of small beams: small beams in accordance with the strength and deflection calculation of simple beams, small bars in the upper bar. According to the small bar scaffold board and live loads above the maximum bending moment and deformation the uniform load calculation of small bar.

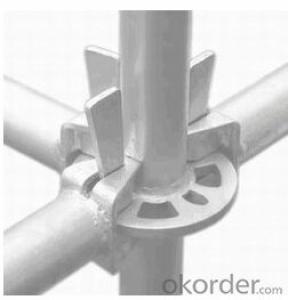

- Q: Bowl buckle type steel pipe scaffolding should set up a few people

- The utility model relates to a bowl buckle joint which is composed of an upper bowl buckle, a lower bowl buckle, a cross bar joint and a limit pin on the upper bowl buckle. A limiting pin is arranged on the vertical rod to weld the lower bowl buckle and the upper bowl buckle. Welding plug on the bar and the diagonal bar. When the utility model is assembled, the transverse rod and the inclined rod are inserted into the lower bowl buckle, and the upper bowl buckle is pressed and rotated.

- Q: does anyone know where i can find dimmesdale's confession (at night) of his sins upon the scaffold.?

- Dimmesdale does not confess to his crimes on the scaffold at night, but he does meet with Hester and little Pearl on the scaffold while Chillingsworth watches. (pg. 220) His public confession comes at the end of the book during the day time and then he dies.(pg. 367) Follow the link I have attached and type in the page numbers in the little box near the top of the page.

- Q: Rather than buy tensile steel rods to reinforce concrete I wonder whether I can effectively recycle scaffold tubes that are presently on my roof.

- You can, but I can think of two reasons why it might be unwise. Firstly, reinforcing bars are ribbed to provide a key between the concrete and the steel, whereas scaffolding bars are much smoother. This leads me to believe that scaffolding bars, weight for weight, wouldn't be as effective as reinforcement bars and you wouldn't have as much reinforcing action as you think. In extremis, you could end up with an under-reinforced concrete beam which will be brittle - reinforced concrete is usually deliberately slightly over-reinforced so that the behaviour close to failure is ductile, as it gives you time to run away. Secondly, scaffolding bars are hollow and reinforcement bars are solid. In reinforced concrete, the alkalinity of the cement paste helps to protect the reinforcement from corrosion - the reason for specifying a minimum cover - but the inside of your scaffolding bars would not benefit from this and so I'd worry about the risk of shortened life due to rusting from the inner face. At least when reinforcement bars rust they tends to spall the concrete cover off, which you see happening.

- Q: Compared to Pankou scaffolding and scaffolding have what distinction, what are the advantages

- 5, Pankou scaffold disassembly do very simple, a person needs only a hammer can do the installation and removal of the entire process. Construction efficiency greatly improved, two construction workers only 1 days to complete the construction site 350m3.

Send your message to us

Metral Scaffolding System with En12810 Standard and SGS Certified CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords