Metallic Material Steel Iron Rods for Construction Concrete

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Metallic Material Steel Iron Rods for Construction Concrete

Description of Metallic Material Steel Iron Rods

1, Diameter: 5.5mm-10mm Metallic Material Steel Iron Rods

10m- 40mm Metallic Material Steel Iron Rods

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition of Metallic Material Steel Iron Rods

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

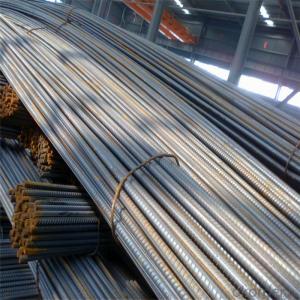

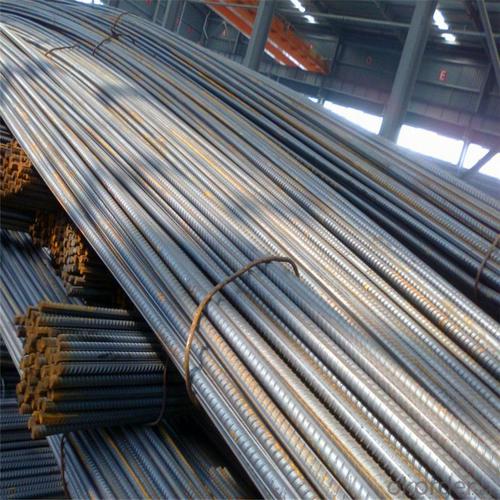

Products Show of Metallic Material Steel Iron Rods

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the applications of special steel in the aerospace sector?

- Due to its exceptional properties and capabilities, special steel finds numerous applications in the aerospace sector. Firstly, it is utilized in the manufacturing of aircraft engines. Special steel's high strength and temperature resistance make it an ideal choice for components such as turbine blades and discs, which experience extreme heat and stress during operation. Moreover, special steel provides excellent corrosion resistance, ensuring the durability and reliability of vital engine parts. Another important application of special steel in the aerospace sector involves constructing aircraft structures. Special steel alloys are employed to fabricate landing gear, wing components, and other structural elements. The high strength-to-weight ratio of special steel enables the production of lightweight yet sturdy structures, contributing to fuel efficiency and overall performance. Special steel is also essential in producing aerospace fasteners, including bolts, nuts, and screws that secure various aircraft components together. Special steel's exceptional mechanical properties, fatigue resistance, and vibration resistance make it an ideal material for fasteners, ensuring the integrity and safety of aircraft assemblies. Furthermore, special steel is utilized in aerospace tooling and equipment. Tools used in the manufacturing process, such as cutting tools and molds, are often made from special steel. Its high hardness and wear resistance enable efficient and precise machining of aerospace components. Additionally, special steel is employed in the production of specialized equipment, such as test rigs, calibration devices, and ground support equipment, which are crucial for aerospace operations and maintenance. In conclusion, special steel plays a crucial role in the aerospace sector, contributing to the overall safety, performance, and reliability of aerospace systems. Its use in aircraft engines, structures, fasteners, and tooling is indispensable for the demanding and critical applications within the aerospace industry, thanks to its unique properties.

- Q: What are the applications of special steel in the manufacturing sector?

- Special steel has a wide range of applications in the manufacturing sector, including the production of tools, machinery, automotive components, and construction materials. Its exceptional strength, durability, and resistance to corrosion make it ideal for manufacturing applications that require high performance and reliability. Furthermore, special steel can be tailored to specific requirements, enabling manufacturers to create customized products with enhanced properties, such as heat resistance or hardness. Overall, special steel plays a crucial role in various industries, contributing to the advancement and efficiency of the manufacturing sector.

- Q: What are the common challenges in welding titanium alloys?

- Welding titanium alloys presents various difficulties due to the unique properties of titanium. Firstly, the melting point of titanium is exceptionally high, reaching approximately 1668°C (3034°F). This necessitates the use of specialized equipment and techniques to attain optimal welding conditions. Moreover, this high melting point increases the risk of overheating, which can lead to distortion or warping of the welded components. Another challenge lies in titanium's strong reactivity with oxygen, nitrogen, and hydrogen. These gases can easily contaminate the weld pool during the welding process, resulting in the formation of brittle and porous welds. Therefore, it is essential to take rigorous measures such as utilizing inert shielding gases like argon or helium, maintaining a high level of cleanliness, and employing proper welding techniques like gas tungsten arc welding (GTAW) to minimize contamination and achieve sound welds. Titanium also exhibits a significant affinity for carbon, which can cause the formation of brittle intermetallic compounds during welding. To prevent this, it is crucial to employ low-carbon filler metals and ensure appropriate heat input to avoid carbon diffusion into the weld zone. Furthermore, titanium alloys possess low thermal conductivity, causing heat generated during welding to concentrate in a small area. This concentration leads to localized overheating and potential damage. Hence, it is vital to control heat input and utilize suitable welding techniques to distribute heat evenly, thereby avoiding overheating and preserving the integrity of the welded joint. Lastly, titanium alloys display a high coefficient of thermal expansion, resulting in significant thermal expansion and contraction throughout the welding process. This can lead to distortion and residual stresses in the welded components. To mitigate these issues, preheating and post-weld heat treatment may be required to minimize distortion and relieve residual stresses. In conclusion, the challenges in welding titanium alloys encompass a high melting point, reactivity with gases, potential contamination, formation of intermetallic compounds, low thermal conductivity, and significant thermal expansion. By comprehending these challenges and implementing suitable welding techniques, it is possible to overcome these difficulties and achieve high-quality welds in titanium alloys.

- Q: Can special steel be used in the manufacturing of cutting-edge technology products?

- Yes, special steel can be used in the manufacturing of cutting-edge technology products. Special steel, such as high-strength alloys or stainless steel, offers various desirable properties like durability, corrosion resistance, and high strength-to-weight ratio. These characteristics make it suitable for the production of components used in advanced technology products like smartphones, laptops, aerospace equipment, and medical devices.

- Q: What are the different casting techniques used for special steel?

- There are several casting techniques used for special steel, including investment casting, sand casting, centrifugal casting, and continuous casting. Each technique has its own advantages and is suitable for specific applications. Investment casting is known for its precision and ability to produce intricate shapes, while sand casting is cost-effective and versatile. Centrifugal casting is used to create cylindrical shapes with high strength, and continuous casting is employed for mass production of steel products.

- Q: Can special steel be used in the production of surgical implants?

- Yes, special steel can be used in the production of surgical implants. Special steel, such as stainless steel, is often preferred for surgical implants due to its high strength, corrosion resistance, and biocompatibility. It is commonly used for various types of implants, including orthopedic, dental, and cardiovascular implants.

- Q: Can special steel be used in the food packaging industry?

- Yes, special steel can be used in the food packaging industry. Special steel alloys, such as stainless steel, are commonly used in food packaging due to their corrosion resistance, durability, and ability to maintain product integrity. These properties make special steel suitable for applications where hygiene, safety, and longevity are essential, making it an ideal choice for various food packaging materials and equipment.

- Q: How does special steel contribute to improving product efficiency in energy-intensive processes?

- Special steel plays a crucial role in improving product efficiency in energy-intensive processes due to its unique properties. Its superior strength, durability, and heat resistance allow for the design and manufacturing of more efficient and high-performing equipment. By using special steel components, energy-intensive processes can operate at higher temperatures, withstand harsh conditions, and reduce material wear, resulting in increased productivity, reduced downtime, and ultimately, improved energy efficiency.

- Q: How does special steel contribute to the manufacturing aftermarket industry?

- The manufacturing aftermarket industry greatly relies on special steel to enhance the performance, durability, and reliability of components and equipment. Special steel is particularly valuable because it can withstand extreme conditions like high temperatures, corrosive environments, and heavy loads. This makes it an ideal choice for producing critical parts in industries such as automotive, aerospace, energy, and machinery. In the manufacturing aftermarket industry, special steel is commonly used to create replacement parts for machinery or equipment that have deteriorated or been damaged over time. By using special steel, these replacement parts can meet the specifications set by the original equipment manufacturer (OEM) in terms of strength and resilience. Moreover, special steel enables the development of innovative designs and the production of lightweight and efficient components. This leads to improved equipment performance, reduced energy consumption, and increased productivity. For instance, in the automotive industry, special steel is used to make lightweight engine components, resulting in better fuel efficiency and lower emissions. Furthermore, the use of special steel in the manufacturing aftermarket industry helps to reduce maintenance and downtime costs. By using high-quality steel, the longevity of replacement parts is increased, reducing the need for frequent repairs or replacements. Consequently, this decreases production downtime and associated expenses while enhancing overall equipment reliability. Additionally, special steel offers a wide range of customization possibilities, allowing manufacturers to tailor the material properties to meet specific requirements. This flexibility enables the development of unique solutions and the production of specialized components that meet the demands of different industries. It also enables manufacturers to address specific challenges related to wear resistance, hardness, or toughness, which are crucial factors in the aftermarket industry. In conclusion, special steel plays a crucial role in the manufacturing aftermarket industry by enhancing the performance, durability, and reliability of replacement parts. Its ability to withstand extreme conditions, enable innovative designs, reduce maintenance costs, and offer customization options make it an indispensable material in the production of components and equipment across various industries.

- Q: How does special steel perform in high-temperature hydrogen environments?

- Special steel is known for its excellent performance in high-temperature hydrogen environments. It exhibits superior resistance to hydrogen embrittlement, corrosion, and material degradation, making it a suitable choice for applications where exposure to high-temperature hydrogen is prevalent. The steel's unique composition and heat treatment processes enhance its mechanical properties and enable it to maintain its structural integrity even in challenging conditions. Overall, special steel demonstrates remarkable performance and reliability when subjected to high-temperature hydrogen environments.

Send your message to us

Metallic Material Steel Iron Rods for Construction Concrete

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords