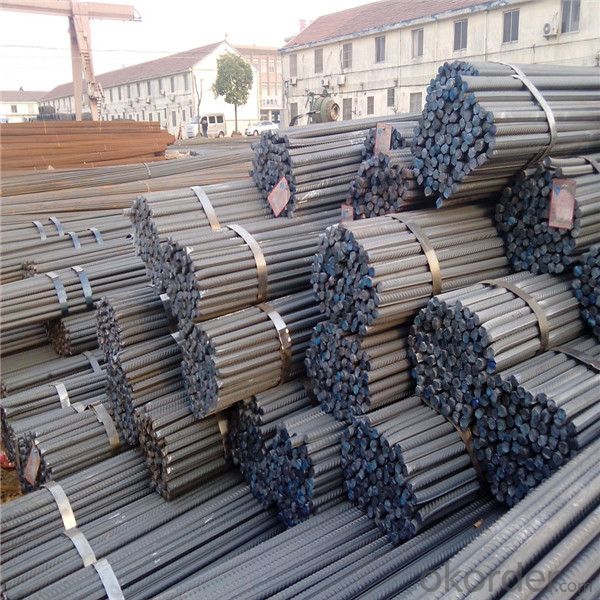

Iron rods for construction in stock for sale

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 19863 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel rebar is bars of steel commonly used in construction, especially for reinforcing concrete structures such as

driveways, foundations, walls, and columns. These bars come in different sizes and strength grades, and can be

smooth or may include deformations that provide greater adhesion for concrete poured over the bars. When used

in poured concrete, the bars are typically placed in a grid pattern, the concrete poured over them, and then readjusted

to maintain the proper shape while the concrete sets. Steel rebar can be purchased from a number of manufacturers

and is often found at construction retailers or large hardware stores

Our Advantage:

High quality steel products from 1 class mills in China

Reasonable price

Professionalism of the products

On-time delivery

Complete documents and certificates

Sincere service to meet our clients' requirements

Product Description :

Chemical composition (%): | Steel | C | Si | Mn | P | S | Ceq | ||||

HRB335 |

0.25 |

0.80 |

1.60 |

0.045 |

0.045 | 0.52 | |||||

HRB400 | 0.54 | ||||||||||

HRB500 | 0.55 | ||||||||||

Mechanical properties | Steel | Rel/ MPa | Rm/ MPa | A/ % | Agt/ % | ||||||

≥ | |||||||||||

HRB335 | 335 | 455 | 17 |

7.5 | |||||||

HRB400 | 400 | 540 | 16 | ||||||||

HRB500 | 500 | 630 | 15 | ||||||||

Package: | Standard export packing or as customer's request | ||||||||||

Application: | Construction, building, bridge, road. ect | ||||||||||

Payment terms | 1).100% irrevocable L/C at sight. | ||||||||||

Delivery time | 15-30 days after receipt of L/C or deposit by T/T | ||||||||||

Features

1、Pure steel quality, stable chemical contents, small tolerance.

2、Constant Quality, good drawing performance.

3、High dimension accuracy degree, accuracy degree of Level C up to 80%, smooth surface, less scale, easy to be pickled.

4、Automatic bundling with 4 lines by Machine in tidy and good looks

5、Big high quality percentage, small coil percentage, and heavy coil weight for Hard Coil.

6、High sorbitizing percentage.

Packing:

In bundles, each bundle weight 3.5 tons. Load by container or by bulk verssel.

Our service

(1) We cooperate with famous factories with advanced equipment and well trained workers.

(2) We can provide factory price with trading company service.

(3) We continuously work on the improvement of our processes, guaranteeing consistently high standards

of quality to keep none compensation.

(4) We guarantee 24 hours response and 48 hours solution providing service.

(5) We accept small order quantity before formal cooperation.

(6) We deliver the agreed quality at the agreed time, reacting to changes in customer wishes in a flexible way.

(7) Due to our volume and selling power, we have excellent freight rates with shipping lines.

(8) We strive to always be fair and honest in our dealings with customers.

(9) We strive to work together with customers to achieve much more than we can achieve alone.

(10) Through our passion and commitment we aim to be a market leader in all our key markets. To maintain

our position as market leader we must continue to add value in all that we do.

FAQ:

1.Q: What's your MOQ(minimum order quantity)?

A: One full container, mixed acceptable .

2. Q: What's your packing methods?

A: Packed in bundle or bulk ..

3. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

4. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

5. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q: What is the purpose of ribbed steel rebars?

- The purpose of ribbed steel rebars is to provide reinforcement and enhance the strength of concrete structures, such as buildings, bridges, and roads. The ribs on the rebar increase the bond between the steel and concrete, preventing slippage and improving the overall structural integrity.

- Q: Are steel rebars fire-resistant?

- Yes, steel rebars are fire-resistant. Due to their high melting point and the protective oxide layer that forms when exposed to heat, steel rebars can withstand high temperatures and maintain their structural integrity during a fire.

- Q: How do steel rebars contribute to the overall durability and service life of concrete structures?

- Steel rebars contribute to the overall durability and service life of concrete structures in several ways. Firstly, steel rebars are used in concrete structures to enhance their tensile strength. While concrete is strong in compression, it is relatively weak in tension. By adding steel rebars, which have high tensile strength, to the concrete, the overall strength and load-bearing capacity of the structure are significantly increased. This helps the structure to withstand external forces such as wind, earthquakes, or heavy loads, reducing the risk of structural failure and increasing its overall durability. Secondly, steel rebars play a crucial role in preventing cracking and controlling the propagation of cracks in concrete structures. Concrete has a tendency to shrink and crack when it dries and undergoes temperature changes. The presence of steel rebars helps to distribute these forces and stresses throughout the structure, minimizing the formation and widening of cracks. By restricting crack propagation, the rebars contribute to the overall structural integrity and longevity of the concrete structure. Furthermore, steel rebars provide reinforcement against corrosion. Concrete is highly alkaline, which creates a protective layer around the steel rebars, known as the passivation layer. This layer prevents the steel rebars from rusting and corroding when exposed to moisture or aggressive chemicals. By maintaining the integrity of the rebars, the overall durability and service life of the concrete structure are enhanced. In addition, steel rebars are essential in improving the structural stability and resilience of concrete structures. By providing reinforcement and stiffness to the concrete, they help to distribute and dissipate the applied loads and stresses evenly. This reduces the risk of localized failure and increases the ability of the structure to withstand external forces and deformations. The presence of steel rebars also improves the structural behavior of the concrete, making it more resilient to dynamic forces such as vibrations or impacts. Overall, steel rebars significantly contribute to the overall durability and service life of concrete structures. They enhance the tensile strength of the concrete, prevent cracking and control crack propagation, provide reinforcement against corrosion, and improve the structural stability and resilience. By incorporating steel rebars in concrete construction, engineers can create robust and long-lasting structures that can withstand various challenges and ensure the safety and longevity of the built environment.

- Q: What is the impact of steel rebars on the aesthetics of a structure?

- Steel rebars, being an essential component of reinforced concrete structures, generally have minimal impact on the aesthetics of a building. They are typically concealed within the structure and remain hidden from view. However, in certain architectural designs where rebars are intentionally exposed, they can contribute to an industrial or modern aesthetic. Overall, the impact of steel rebars on the aesthetics of a structure is largely dependent on the design intent and whether they are meant to be visible or not.

- Q: How do steel rebars affect the flexural strength of reinforced concrete elements?

- Steel rebars have a significant impact on the flexural strength of reinforced concrete elements. The presence of rebars in concrete elements enhances their ability to resist bending or flexural forces. Rebars, which are made of high-strength steel, are embedded within the concrete to provide tensile strength. Concrete is a strong material in compression but weak in tension. By incorporating rebars, the resulting composite material benefits from the high compressive strength of concrete and the excellent tensile strength of steel. When a flexural load is applied to a reinforced concrete element, such as a beam or a slab, the rebars distribute the load across the section, effectively resisting the tendency of the concrete to crack and fail under tension. The rebars act as reinforcements, resisting the tensile forces that arise due to bending, thereby increasing the flexural strength of the structure. The size, spacing, and arrangement of the rebars play a crucial role in determining the flexural strength of reinforced concrete elements. The proper design and placement of rebars ensure that they are optimally positioned to resist the anticipated bending forces. This requires careful consideration of factors such as the span of the element, the anticipated loads, and the desired level of strength. Furthermore, the bonding between the rebars and the concrete is essential for transferring bending stresses. Adequate concrete cover over the rebars protects them from corrosion, ensuring their durability and maintaining the integrity of the structure. Corrosion of steel rebars can weaken their bond with the surrounding concrete, compromising the flexural strength of the reinforced element. In summary, steel rebars significantly enhance the flexural strength of reinforced concrete elements by providing the necessary tensile strength to resist bending forces. Proper design, placement, and bonding of rebars are crucial to ensuring the structural integrity and durability of reinforced concrete structures.

- Q: How to calculate the theoretical elongation of finishing thread steel?

- The theoretical elongation of fine thread steel is calculated by L=P.L/ (E.A), P is force, L steel bar is longer, E is elastic, and A is area.

- Q: Can steel rebars be used in structures with limited construction budget?

- Yes, steel rebars can be used in structures with limited construction budget. Steel rebars are commonly used for reinforcement in concrete structures due to their affordability and high strength. They provide structural integrity and enhance the overall durability of the construction. Therefore, using steel rebars in structures with limited budget can be a cost-effective option without compromising the safety and stability of the building.

- Q: What is the maximum length of steel rebars available?

- The specific manufacturer and supplier are the determining factors for the maximum length of steel rebars available. Typically, steel rebars can be found in lengths that range from 6 meters (20 feet) to 18 meters (60 feet). These lengths are established based on various considerations, including transportation logistics, handling capacities, and industry standards within the construction sector. To ascertain the precise maximum length of steel rebars offered, it is crucial to seek guidance from the manufacturer or supplier.

- Q: Can steel rebars be used in composite construction systems?

- Yes, steel rebars can be used in composite construction systems. Steel rebars are commonly used as reinforcement in composite structures to enhance their strength and durability. The rebars are embedded within the composite materials, such as concrete or fiber-reinforced polymers, to provide additional tensile strength and structural integrity. This combination of materials allows for a more efficient and cost-effective construction system.

- Q: Can steel rebars be used in fire-resistant structures?

- Yes, steel rebars can be used in fire-resistant structures. Steel has a high melting point and retains its strength even at high temperatures. However, to enhance fire resistance, additional measures such as fireproof coatings or concrete encasement may be necessary.

Send your message to us

Iron rods for construction in stock for sale

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 19863 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords