FRP Pultrusion Profiles Metal Building Materials Hot Dipped Galvanized Steel Grating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m

- Supply Capability:

- 60000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

FRP guardrail are made by assembling of FRP pultrusion profiles. They divided into four types, they are standard square type, economic type, standard round type and heighten type, the type of profile and the installation distance, height, position and quantity can be changed per the customer’s requirement, the color also could be selected according the client’s demand.

Add the nexus mat on the product surface could make it obtain best corrosion-resistance and anti-ageing properties. The fiberglass content in pultrusion profile is usually 45%-75% (weight ratio), the balance is resin and additive. Unsaturated polyester resin and vinyl resin are the most commonly used resin base.

FEATURES

a. anti-corrosion, anti-rust

b. light weight and high strength

c. vivid color

d. anti-ageing

e. good property of non-magnetism

f. safety

g. easy to installation and maintenance

h. excellent electromagnetism property

DATA

Standard Square type

Handrail | Rung | Post | Kick plate |

Square tube 50*50*4 | Square tube 50*50*4 | Square tube 50*50*4 | Flat panel 101.6*3 |

Economic type

Handrail | Rung | Post | Kick plate |

Channel 57*60*3 | Square tube 38*38*4 | Square tube 50*50*4 | Flat panel 101.6*3 |

Standard round type

Handrail | Rung | Post | Kick plate |

Round tube φ50*4 | Round tube φ50*4 | Round tube φ50*4 | Flat panel 101.6*3 |

Heighten type

Handrail | Rung | Post | Kick plate |

Channel 57*60*3 | Round tube 32*3 | Square tube 50*50*4 | Flat panel 101.6*3 |

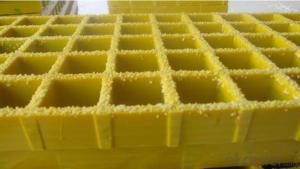

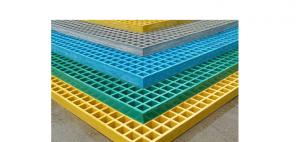

PICTURES

- Q: Can FRP pultrusion profiles be used in the mining and mineral processing industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the mining and mineral processing industry. FRP pultrusion profiles have several properties that make them suitable for use in this industry. Firstly, FRP pultrusion profiles are lightweight yet incredibly strong. This makes them ideal for applications where weight reduction is important, such as in mining equipment or processing plants. Despite their lightweight nature, FRP profiles can withstand heavy loads and resist corrosion, which is particularly beneficial in the mining industry where equipment is exposed to harsh environments and corrosive substances. Secondly, FRP pultrusion profiles are non-conductive and possess excellent electrical insulation properties. This is advantageous in mining and mineral processing operations where electrical safety is paramount. FRP profiles can be used in applications where electrical conductivity needs to be avoided, such as in electrical enclosures or cable trays. Additionally, FRP pultrusion profiles are highly resistant to chemicals, including acids and alkalis. This makes them suitable for use in mineral processing plants where various corrosive chemicals are used in the extraction and processing of minerals. FRP profiles can withstand exposure to these chemicals without deteriorating or experiencing significant damage, prolonging their lifespan and reducing maintenance costs. Furthermore, FRP pultrusion profiles have a high strength-to-weight ratio, which means they can be used to create durable and lightweight structures. This is particularly beneficial in mining operations where structures such as walkways, ladders, and platforms need to be installed in challenging terrains. The lightweight nature of FRP profiles makes them easier to transport, handle, and install compared to traditional materials like steel. In conclusion, FRP pultrusion profiles can be effectively used in the mining and mineral processing industry due to their lightweight, high strength, corrosion resistance, electrical insulation, and chemical resistance properties. These profiles offer numerous advantages over traditional materials, making them a viable option for various applications in this industry.

- Q: How do FRP pultrusion profiles perform in high-temperature applications?

- FRP pultrusion profiles have excellent performance in high-temperature applications. Their inherent thermal stability and resistance to heat make them ideal for use in environments where temperatures can reach extreme levels. These profiles can withstand high temperatures without losing their structural integrity, dimensional stability, or mechanical properties. Additionally, FRP pultrusion profiles have low thermal conductivity, which helps to minimize heat transfer and maintain a stable temperature. Overall, they are a reliable choice for high-temperature applications due to their exceptional heat resistance and durability.

- Q: Are FRP pultrusion profiles resistant to biological growth, such as mold or mildew?

- FRP pultrusion profiles are highly resistant to biological growth, such as mold and mildew. These profiles have a non-porous structure that makes it difficult for microorganisms to attach and grow. They are typically made with a combination of resin and glass fibers, both of which naturally resist biological growth. In contrast to materials like wood or metal, FRP does not create an ideal environment for mold or mildew. The smooth and non-porous surface of FRP prevents moisture absorption, which is necessary for microorganisms to thrive. Additionally, FRP materials lack organic compounds that can support the growth of mold or mildew, thus enhancing their resistance to biological degradation. When it comes to applications that require resistance to biological growth, FRP pultrusion profiles offer a significant advantage over other materials. They are commonly used in environments with high humidity, moisture, or water exposure, such as marine, agricultural, or wastewater treatment facilities. Furthermore, FRP profiles are frequently employed indoors in areas where mold or mildew growth is a concern, such as sanitary areas or food processing plants. Overall, FRP pultrusion profiles are an excellent solution for combating biological growth, including mold and mildew. Their non-porous nature, combined with the inherent resistance of the materials used in their manufacturing, ensures durability and longevity in environments where microbial growth is a potential issue.

- Q: Can FRP pultrusion profiles be used in the water treatment industry?

- Yes, FRP pultrusion profiles can be used in the water treatment industry. FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their excellent corrosion resistance, high strength, and durability. These properties make them suitable for various applications in the water treatment industry. FRP pultrusion profiles can be used in the construction of water treatment tanks, pipes, and other infrastructure. They are resistant to chemicals, including the harsh chemicals often used in water treatment processes. This corrosion resistance ensures a longer lifespan for the equipment and reduces maintenance costs. Additionally, FRP pultrusion profiles have a high strength-to-weight ratio, making them ideal for applications that require lightweight yet strong materials. This allows for easier installation and transportation of water treatment equipment. Furthermore, FRP pultrusion profiles offer design flexibility. They can be manufactured in various shapes and sizes to meet specific project requirements. This allows for customization and optimization of water treatment systems, ensuring efficient and effective water treatment processes. Overall, FRP pultrusion profiles are a reliable and cost-effective choice for the water treatment industry. They provide excellent corrosion resistance, high strength, and design flexibility, making them suitable for various applications in water treatment systems.

- Q: What is the compression strength of FRP pultrusion profiles?

- The compression strength of FRP (Fiber Reinforced Polymer) pultrusion profiles varies depending on several factors such as the type of resin, fiber orientation, and design. However, on average, FRP pultrusion profiles have a compression strength ranging from 10,000 to 50,000 pounds per square inch (psi). It is important to note that these values are approximate and may vary depending on the specific application and intended use of the FRP profiles. Additionally, manufacturers typically provide technical data sheets that outline the compression strength and other mechanical properties of their FRP pultrusion products, which can be utilized for more accurate and reliable information.

- Q: How do FRP pultrusion profiles handle cyclic torsion loads?

- FRP pultrusion profiles are designed to handle cyclic torsion loads effectively due to their inherent properties. The continuous fibers in the profiles provide high strength and stiffness, enabling them to withstand repeated twisting without deformation or failure. Additionally, the resin matrix used in the pultrusion process offers excellent fatigue resistance, ensuring long-term durability and performance under cyclic torsion loads.

- Q: Are FRP pultrusion profiles resistant to caustic solutions?

- FRP pultrusion profiles are known for their resistance to caustic solutions. The combination of reinforcing fibers and the polymer matrix used in FRP pultrusion provides exceptional chemical resistance. Unlike traditional materials like steel or wood, which can be corroded or degraded by strong alkaline substances, FRP pultrusion profiles are highly resistant to chemical attack. This makes them suitable for industries that frequently encounter caustic solutions, such as chemical processing, wastewater treatment, and marine environments. However, it is important to refer to the manufacturer's specifications and guidelines to ensure compatibility between specific caustic solutions and the chosen FRP pultrusion profile.

- Q: Can FRP pultrusion profiles be used in infrastructure projects?

- Yes, FRP pultrusion profiles can be used in infrastructure projects. These profiles are lightweight, durable, and corrosion-resistant, making them ideal for applications in bridges, walkways, railings, and other structural components. They offer high strength-to-weight ratios and can be customized to meet specific project requirements. Additionally, FRP pultrusion profiles are non-conductive, making them suitable for electrical infrastructure projects.

- Q: Can FRP pultrusion profiles be used in the automotive manufacturing industry?

- Certainly! Fiber Reinforced Polymer (FRP) pultrusion profiles have the potential to be utilized within the automotive manufacturing sector. These profiles possess a number of advantages that render them appropriate for automotive applications. To begin with, one of the key benefits of FRP profiles is their lightweight nature, which aids in reducing the overall weight of vehicles. This is of utmost importance in enhancing fuel efficiency and decreasing emissions. Moreover, the reduced weight of FRP profiles enables improved handling and enhanced performance. Additionally, FRP profiles exhibit exceptional mechanical properties, including high strength and stiffness. These properties make them well-suited for integration into structural components of vehicles, such as chassis, body panels, and frames. FRP profiles are able to withstand heavy loads and offer excellent impact resistance, thereby ensuring the safety of both the vehicle and its occupants. Furthermore, FRP profiles possess outstanding corrosion resistance, a quality that is particularly advantageous in automotive applications. In contrast to traditional materials like steel, FRP profiles are impervious to rust and corrosion. Consequently, they are ideally suited for deployment in various automotive environments, including those that involve exposure to moisture, chemicals, and salt. Moreover, FRP pultrusion profiles can be customized to meet specific design requirements, thereby affording flexibility in the manufacturing process. They can be produced in a range of shapes and sizes, which allows for the design of intricate components. This design flexibility also permits customization and optimization of vehicle performance. Lastly, FRP profiles possess excellent thermal and electrical insulation properties. This renders them appropriate for applications where minimizing electrical conductivity or providing thermal insulation is necessary. On the whole, the combination of the lightweight nature, high strength, corrosion resistance, design flexibility, and insulation properties of FRP pultrusion profiles positions them as an ideal choice for deployment within the automotive manufacturing industry. Their usage can contribute to the development of more efficient, safe, and durable vehicles.

- Q: Can FRP pultrusion profiles be used in the construction of conveyor systems?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be effectively used in the construction of conveyor systems. FRP pultrusion profiles offer several advantages that make them suitable for such applications. Firstly, FRP pultrusion profiles are lightweight yet strong, making them ideal for conveyor system construction. Their high strength-to-weight ratio allows for easy installation and maintenance, reducing the overall weight of the system while maintaining structural integrity. This feature is particularly beneficial when designing and building long-span conveyor systems. Secondly, FRP pultrusion profiles are highly corrosion-resistant. Unlike traditional materials like steel or aluminum, FRP pultrusions are resistant to rust, chemicals, and moisture. This resistance makes them suitable for conveyor systems that may be exposed to harsh environments or corrosive substances, such as in mining or chemical industries. Another advantage of FRP pultrusion profiles is their electrical insulation properties. They do not conduct electricity, which is a crucial requirement in conveyor systems where electrical components are present. This property ensures a higher level of safety and reduces the risk of electrical hazards. Furthermore, FRP pultrusion profiles can be easily customized to meet specific design requirements. They can be manufactured in various shapes and sizes, allowing for flexibility in conveyor system design. Additionally, FRP profiles can incorporate features such as channels, slots, or reinforcements, which can be advantageous for mounting accessories or facilitating the movement of goods on the conveyor. Lastly, FRP pultrusion profiles are durable and have a long service life. They are resistant to UV degradation and do not require frequent maintenance or painting, reducing lifecycle costs compared to traditional materials. This durability makes them a cost-effective choice for conveyor system construction. In conclusion, FRP pultrusion profiles are an excellent choice for the construction of conveyor systems. Their lightweight, corrosion resistance, electrical insulation properties, customization options, and durability make them a reliable and efficient material for such applications.

Send your message to us

FRP Pultrusion Profiles Metal Building Materials Hot Dipped Galvanized Steel Grating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m

- Supply Capability:

- 60000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords