Membran Weldable and Valcanization for Waterproof System

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 14000 m²

- Supply Capability:

- 90000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Membran Weldable and Valcanization for Waterproof System

Description Of Membrane Weldable:

1. EPDM membrane is made from ternary ethylene-propylene rubber, which is for waterproofing of exposed and non-exposed applications.

2. EPDM membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. EPDM membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Membran Weldable and Valcanization for Waterproof System

1. High puncture resistance

2. High aging resistance

3. UV resistance

Membran Weldable and Valcanization for Waterproof System

Material | Ternary Ethylene-Propylene rubber |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Applications of Membran Weldable and Valcanization for Waterproof System

1. Industrial and civil building waterproofing

2. Geosynthetic liner for swimming pool, channels, irrigation system

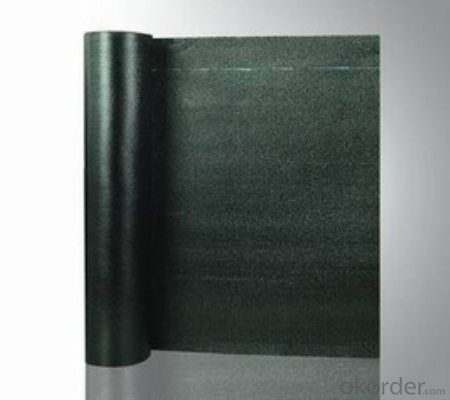

IMages of Membran Weldable and Valcanization for Waterproof System

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 15 countries in the past 10 years.

3. How long do we usually reply your request?

We always reply our customer within 4 hours.

- Q: Can a waterproofing membrane be used in residential buildings?

- Absolutely, residential buildings can indeed utilize a waterproofing membrane. In fact, it is highly advisable due to its ability to effectively block moisture, thus preventing any water-related harm or growth of mold. Areas in residential buildings that are prone to water exposure, such as basements, bathrooms, roofs, and balconies, commonly employ waterproofing membranes. These membranes are typically applied on either the exterior or interior surfaces, creating a protective layer that hinders water infiltration. Consequently, this aids in preserving the building's structural integrity, prolonging its lifespan, and augmenting the overall comfort and safety of its inhabitants. Therefore, incorporating a waterproofing membrane into residential buildings is a prudent investment for safeguarding against potential water-related complications.

- Q: Can waterproofing membranes be used on green roofs?

- Yes, waterproofing membranes can be used on green roofs. In fact, they are an essential component of green roof systems as they prevent water leakage and protect the underlying structure. Waterproofing membranes are specifically designed to withstand the unique challenges posed by green roofs, such as water infiltration and root penetration, ensuring the longevity and effectiveness of the green roof system.

- Q: Can a waterproofing membrane be used in conjunction with insulation materials?

- Using both insulation materials and a waterproofing membrane together is often recommended in order to protect buildings from moisture and improve energy efficiency. The waterproofing membrane acts as a barrier against water infiltration, while the insulation materials help regulate temperature and minimize heat loss or gain. By combining these components, the building envelope can effectively shield against water damage and maintain a comfortable indoor environment. Proper installation and compatibility between the waterproofing membrane and insulation materials are crucial for achieving optimal performance and long-lasting results.

- Q: Can a waterproofing membrane be used on sloped surfaces?

- Yes, a waterproofing membrane can be used on sloped surfaces. In fact, it is commonly used on sloped surfaces such as roofs, balconies, and terraces to prevent water infiltration and ensure effective drainage. The membrane is designed to provide a durable and flexible barrier that can accommodate the movement and incline of sloped surfaces, helping to protect the underlying structure from moisture damage.

- Q: Can a waterproofing membrane be used in areas with extreme temperatures?

- Yes, a waterproofing membrane can be used in areas with extreme temperatures. Many waterproofing membranes are designed to withstand a wide range of temperatures, from extremely hot to extremely cold. These membranes are made from materials that are resistant to cracking, melting, or becoming brittle in extreme temperatures. Additionally, some waterproofing membranes are specifically engineered for use in areas with extreme temperatures, such as those found in arctic or desert environments. It is important to choose a waterproofing membrane that is suitable for the specific temperature range of the area in which it will be used to ensure its effectiveness and longevity.

- Q: Can a waterproofing membrane be used in high-rise buildings?

- Yes, a waterproofing membrane can be used in high-rise buildings. It is commonly utilized in high-rise buildings to prevent water infiltration and protect the structure from potential damages caused by moisture. The membrane is applied to various surfaces such as roofs, foundations, and walls to create a barrier against water penetration, ensuring the building remains dry and structurally sound.

- Q: Can a waterproofing membrane be used in interior or exterior applications?

- A waterproofing membrane can be utilized in both interior and exterior scenarios. When used indoors, such as in basements or bathrooms, the membrane can be applied to walls or floors to effectively prevent water or moisture infiltration. This safeguard shields the underlying structure from potential harm caused by water intrusion. For exterior applications, the waterproofing membrane can be employed on the outer walls or foundations of a building to effectively repel water. This becomes particularly crucial in regions with heavy rainfall or high water tables. By creating a barrier against water, the membrane effectively maintains a dry and water-free interior environment for the building. In conclusion, the utilization of a waterproofing membrane in both interior and exterior contexts is absolutely necessary in order to ensure the longevity and durability of a structure by effectively safeguarding it against water-related issues.

- Q: How does a waterproofing membrane handle movement or settling of a building?

- A waterproofing membrane is designed to accommodate movement or settling of a building in a few different ways. Firstly, it is typically installed in such a way that it can stretch or flex as the building moves. This elasticity allows the membrane to remain intact and continue to provide a watertight seal even as the structure shifts or settles. Additionally, waterproofing membranes often incorporate reinforcement materials, such as fabrics or fibers, which enhance their ability to withstand movement. These reinforcements help distribute the stress or strain caused by building movement across a larger area, reducing the risk of tears or failures in the membrane. Furthermore, some waterproofing membranes are designed with built-in features that can accommodate significant movement. For example, certain membranes may have special "crack-bridging" properties, which allow them to span small cracks that may develop in the building's substrate due to settling. This ensures that the membrane remains effective even if the structure experiences minor damage. In cases where a building is expected to undergo significant movement or settling, specialized waterproofing systems, such as joint sealants or expansion joints, may be used in combination with the membrane. These systems are specifically designed to handle large or dynamic movements, providing additional protection against water infiltration. Overall, a waterproofing membrane is carefully designed and installed to handle the movement or settling of a building. Its elasticity, reinforcement materials, and additional features allow it to remain effective in maintaining a watertight seal, even in the face of structural shifts or settlement.

- Q: Does a waterproofing membrane prevent water damage to building materials?

- Yes, a waterproofing membrane is designed to create a barrier that prevents water from seeping into building materials, thus effectively preventing water damage.

- Q: What are the different thickness options for a waterproofing membrane?

- The different thickness options for a waterproofing membrane typically range from 10 mils to 40 mils, with some specialty options available in even greater thicknesses.

Send your message to us

Membran Weldable and Valcanization for Waterproof System

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 14000 m²

- Supply Capability:

- 90000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords