Melt Extract Stainless Steel Fiber Reinforced Wavy Shear-Cut Concrete Admixtures

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 kg

- Supply Capability:

- 250000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Shandong, China (Mainland)

Model Number: steel fiber

material: steel wire

application: concrete reinocement

type: end hook steel fiber

Product features

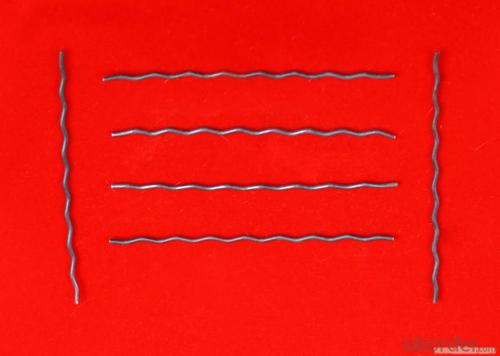

Steel band shearing type steel fiber

Good quality, low price, high cost performance

Product overview

1, through the ISO9001 certification

More than

2, Material: low carbon steel strip

3. Shape: Wave

4. Multi anchorage points, rolling force is good

5. good quality, low price, high cost performance

wavy steel fiber

1, the length of 15 - 50 mm

2, the diameter of 0.5-1.2 mm

3, the intensity is 380-600 mpa

Specifications

1.hooked steel fiber

2.CE and ISO9001:2008

3.diameter from 0.5mm to 1.2mm

4.competitive price,high quality and service

Hooked Steel Fiber:

1.Diameter:0.5mm-1.0mm

2.Length: 25mm-60mm

3.Material: low carbon steel wire

4.Feature: excellent tensile,high tenacity,against cracking,impact and fatigue

5.Uses: high way,tunnel,building,airport road serface and so on .

Picture

steel fiber concrete reinforced

FAQ

we can produce any type steel fiber and of course we can make production according to your requirement

we have specilize in this field for almost 10 years ,with good quality and competitive price

- Q: How does melt extract stainless steel fiber improve the freeze-thaw resistance of concrete?

- An innovative material known as melt extract stainless steel fiber greatly improves the freeze-thaw resistance of concrete. This particular fiber is obtained from stainless steel using a specialized extraction process that guarantees its purity and high-quality characteristics. When concrete is subjected to freezing and thawing cycles in cold weather conditions, its ability to withstand these cycles is referred to as freeze-thaw resistance. Freezing water within the concrete expands, exerting pressure on the surrounding material. Over time, this pressure can lead to cracks, spalling, and other forms of deterioration in the concrete structure. By incorporating melt extract stainless steel fibers into the concrete mix, several mechanisms work together to enhance its freeze-thaw resistance. Firstly, these fibers act as reinforcement within the concrete matrix, providing additional tensile strength and reducing the formation and spread of cracks. As a result, the overall structural integrity of the concrete is preserved even when exposed to freeze-thaw cycles. Furthermore, the stainless steel composition of these fibers offers excellent resistance to corrosion. Concrete is often exposed to various environmental factors, including chloride ions from de-icing salts, which can accelerate the corrosion process. However, the use of stainless steel fibers prevents the corrosion of embedded reinforcing steel, thereby maintaining the durability and freeze-thaw resistance of the concrete. Moreover, the presence of melt extract stainless steel fibers improves the overall durability of the concrete. These fibers enhance the cohesion and bond between the aggregate and cement paste, resulting in a denser and less permeable concrete matrix. This reduces the entry of water and other harmful substances, such as chloride ions, into the concrete, further protecting it against freeze-thaw damage. In conclusion, melt extract stainless steel fiber plays a vital role in enhancing the freeze-thaw resistance of concrete. Through reinforcement, corrosion resistance, and improved durability, these fibers effectively mitigate the negative effects of freeze-thaw cycles on concrete structures, ensuring their longevity and integrity.

- Q: Can melt extract stainless steel fiber be used in pre-stressed concrete elements?

- Melt extract stainless steel fibers, known for their durability and excellent reinforcement properties, are suitable for pre-stressed concrete elements. By utilizing these fibers, the load-bearing capacity, crack resistance, and structural integrity of the concrete structures can be greatly improved. Moreover, the high tensile strength and corrosion resistance of stainless steel fibers make them perfect for environments with moisture or chemical exposure. Overall, incorporating melt extract stainless steel fibers in pre-stressed concrete elements can substantially enhance the structure's performance and lifespan.

- Q: Does melt extract stainless steel fiber enhance the flexural strength of concrete?

- Yes, melt extract stainless steel fiber can enhance the flexural strength of concrete. When stainless steel fibers are added to concrete, they improve its tensile and flexural properties. The fibers act as reinforcement within the concrete matrix, increasing its resistance to cracking and improving its overall durability. Melt extract stainless steel fibers are specifically designed to have a high aspect ratio, meaning they are long and thin. This characteristic allows them to effectively distribute stress throughout the concrete, enhancing its flexural strength. The addition of stainless steel fibers can significantly increase the energy absorption capacity of concrete, making it more resistant to bending and flexing. This improvement in flexural strength is particularly beneficial in applications where the concrete is subjected to heavy loads or dynamic forces. Moreover, melt extract stainless steel fibers have excellent corrosion resistance, ensuring their long-term effectiveness in concrete structures. They can withstand harsh environmental conditions and exposure to chemicals, maintaining their reinforcement properties over time. In conclusion, the use of melt extract stainless steel fiber can enhance the flexural strength of concrete, improving its ability to withstand bending and flexing forces. This reinforcement leads to more durable and reliable concrete structures.

- Q: How does melt extract stainless steel fiber improve the ductility of shotcrete?

- The ductility of shotcrete is enhanced by melt extract stainless steel fiber, which improves its resistance to deformation and cracking. The inclusion of stainless steel fibers in the shotcrete mix forms a reinforced matrix that increases its tensile strength and flexural capacity. During the application of shotcrete, it undergoes a curing process that results in hardening and increased strength. However, shotcrete is susceptible to cracking when subjected to tensile stresses without any reinforcement. By integrating melt extract stainless steel fibers, the ductility of shotcrete is enhanced as the fibers distribute the tensile forces throughout the material, preventing the formation and spread of cracks. The exceptional properties of stainless steel, such as its high tensile strength and corrosion resistance, make it an ideal material for reinforcing shotcrete. The fibers are evenly dispersed within the shotcrete mix, creating a three-dimensional reinforcement system that improves its structural integrity. The addition of stainless steel fibers also enhances the overall durability of shotcrete. The fibers act as a barrier, preventing the entry of water and other harmful substances, thereby reducing the risk of corrosion and deterioration. This results in a longer service life and reduces the need for expensive maintenance and repairs. In conclusion, the presence of melt extract stainless steel fiber enhances the ductility of shotcrete by reinforcing its structure and improving its ability to withstand tensile stresses and deformation. Incorporating these fibers provides shotcrete with increased strength, durability, and resistance to cracking, ultimately enhancing its performance and extending its lifespan.

- Q: How does melt extract stainless steel fiber improve the resistance to fire in concrete?

- Melt extract stainless steel fiber improves the resistance to fire in concrete by enhancing its ability to withstand high temperatures. The fibers act as reinforcement within the concrete matrix, preventing cracks and spalling during exposure to fire. They also help to dissipate heat more evenly throughout the concrete, reducing the risk of localized thermal stress. This ultimately improves the structural integrity and fire resistance of the concrete, making it a more reliable and durable material in fire-prone environments.

- Q: Can melt extract stainless steel fiber be used in shotcrete or sprayed concrete?

- Yes, melt extract stainless steel fiber can be used in shotcrete or sprayed concrete. It is commonly used as reinforcement in these applications to improve the strength, durability, and crack resistance of the concrete.

- Q: What are the advantages of melt extract stainless steel fiber over other types of steel fibers?

- Melt extract stainless steel fibers offer several advantages over other types of steel fibers. Firstly, melt extract stainless steel fibers have excellent corrosion resistance. Stainless steel contains a high amount of chromium, which forms a protective oxide layer on the surface of the fibers. This oxide layer acts as a barrier against corrosive elements, making them highly resistant to rust and deterioration. This advantage is especially crucial in environments where exposure to moisture, chemicals, or high temperatures is common. Secondly, melt extract stainless steel fibers have superior mechanical properties compared to other steel fibers. These fibers are made by melting the steel and then rapidly extracting it into fine filaments. This process creates fibers with high tensile strength, allowing them to withstand heavy loads and resist deformation under stress. This strength also enhances the durability and lifespan of structures reinforced with melt extract stainless steel fibers. Additionally, melt extract stainless steel fibers have a high melting point, making them suitable for use in high-temperature applications. These fibers can withstand extreme heat without losing their structural integrity, making them ideal for reinforcing concrete in environments such as industrial furnaces, fire-resistant structures, and thermal power plants. Furthermore, the fine and uniform nature of melt extract stainless steel fibers allows for better dispersion throughout the concrete matrix. This results in enhanced crack resistance and improved load-bearing capacity of the reinforced concrete. The small diameter of these fibers also facilitates better bonding with the surrounding concrete, leading to increased bond strength and overall structural performance. Lastly, melt extract stainless steel fibers offer excellent electrical conductivity. This makes them suitable for applications where electrical grounding or conductivity is required, such as in electromagnetic shielding or in structures exposed to electrical currents. In summary, the advantages of melt extract stainless steel fibers include superior corrosion resistance, high mechanical strength, resistance to high temperatures, improved crack resistance, enhanced bond strength, and excellent electrical conductivity. These factors make them a preferred choice over other types of steel fibers for a wide range of applications, including construction, infrastructure, and industrial sectors.

- Q: Can melt extract stainless steel fiber improve the bond strength of concrete to epoxy coatings?

- Yes, melt extract stainless steel fiber can improve the bond strength of concrete to epoxy coatings. Stainless steel fibers are commonly used as reinforcement in concrete to increase its tensile strength and durability. When added to concrete, these fibers help to distribute and dissipate stress, reducing the formation of cracks and improving overall structural integrity. In the case of epoxy coatings, the addition of melt extract stainless steel fibers can provide several benefits. Firstly, the fibers act as a mechanical anchor, enhancing the bond between the concrete and the epoxy coating. This improved bond strength ensures that the coating remains firmly attached to the concrete surface, even under conditions of stress or movement. Secondly, the presence of stainless steel fibers can also help to mitigate the formation of cracks in the epoxy coating. By reinforcing the concrete substrate, these fibers help to distribute any stress or load applied to the coating more evenly, reducing the likelihood of cracks forming due to localized stress concentrations. Furthermore, melt extract stainless steel fibers can also improve the overall durability and lifespan of the epoxy coating. The fibers provide additional protection against impact, abrasion, and other forms of wear and tear that the coating may be subjected to over time. This enhanced durability can result in longer-lasting and more resilient epoxy coatings. In summary, the addition of melt extract stainless steel fiber can significantly improve the bond strength between concrete and epoxy coatings. By enhancing the mechanical connection between the two materials and providing additional reinforcement, these fibers contribute to a stronger, more durable, and longer-lasting bond.

- Q: How does melt extract stainless steel fiber impact the shrinkage cracking of concrete pavements?

- The reduction of shrinkage cracking in concrete pavements can be significantly influenced by the utilization of melt extract stainless steel fiber. Cracks are formed when the concrete undergoes volume reduction due to drying and thermal shrinkage. By incorporating melt extract stainless steel fiber into the concrete mixture, the overall tensile strength and ductility of the concrete are enhanced. These fibers function as reinforcement, effectively distributing stress and preventing crack formation and propagation. Moreover, they aid in controlling plastic shrinkage by reducing the rate of water evaporation from the concrete surface. The stainless steel fibers are uniformly dispersed throughout the concrete matrix, forming a three-dimensional reinforcement system. This reinforcement enhances the concrete's ability to withstand shrinkage stresses, thus decreasing the likelihood of shrinkage cracking. Furthermore, the use of melt extract stainless steel fiber can augment the durability and lifespan of concrete pavements. It heightens the concrete's resistance to abrasion, impact, and fatigue, rendering it more resilient against the strains and pressures exerted by traffic loads. In summary, melt extract stainless steel fiber plays a beneficial role in mitigating shrinkage cracking in concrete pavements. It enhances the concrete's tensile strength, ductility, and resistance to shrinkage stresses, thereby reducing the occurrence of cracks. Additionally, the incorporation of these fibers improves the longevity and reliability of concrete pavements, making them more durable and long-lasting.

- Q: What is the typical fiber length and diameter of melt extract stainless steel fiber?

- The specific manufacturer and application requirements can cause variations in the typical fiber length and diameter of melt extract stainless steel fiber. However, a general range for the length of these fibers is typically from a few millimeters to several centimeters. The diameter of these fibers can range from around 10 micrometers to 50 micrometers. These dimensions are carefully selected to ensure the desired properties, such as strength, durability, and thermal conductivity, for a variety of applications. These applications include reinforcement in composites, thermal insulation, and electromagnetic shielding.

Send your message to us

Melt Extract Stainless Steel Fiber Reinforced Wavy Shear-Cut Concrete Admixtures

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 kg

- Supply Capability:

- 250000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords