Melt Extract Stainless Steel Fiber 446 - High Quality Melt Extract Stainless Steel Fiber

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 5000 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

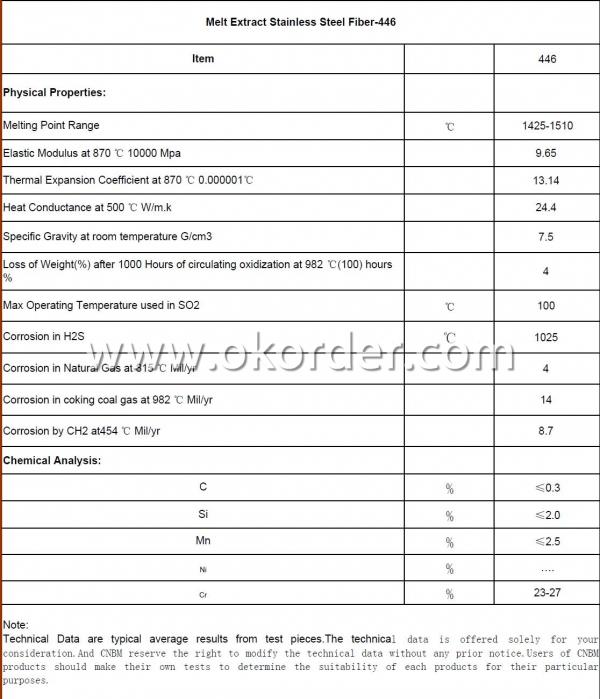

General Information of Melt Extract Stainless Steel Fiber 446

CMAX melt extract stainless steel fiber is produced by melting elements in a crucible. A flywheel is then introduced to the crucible and droplets of molten metal are spun into the open air and hardened.The speed of the wheel determines the fiber length. CMAX melt extract stainless steel fiber can increase the lifetime of refractory materials and industrial furnaces by several times, decreasing cost.

Feature of CMAX Melt Extract Stainless Steel Fiber 446

Improve refractories’performance

Improve refractories’longevity

Improve refractories’durability

Significantly reducing downtime and maintance cost

Application of CMAX Melt Extract Stainless Steel Fiber 446

Refractory products

Precast

Castable project

Industrial furnaces

Other refractories project

Our company has success in its melt extract stainless steel fiber products due to their cost-effectiveness and excellent insulating properties. We also have experience in melt extract stainless steel fiberapplication and would like to assist you in product selection, system design, and installation techniques. Our products of melt extract stainless steel fiber are in good quality and in best price.

- Q: Can melt extract stainless steel fiber be used in refractory concrete applications?

- Yes, melt extract stainless steel fiber can indeed be used in refractory concrete applications. Refractory concrete is a type of concrete that is designed to withstand high temperatures and retain its strength and structural integrity under extreme heat conditions. The addition of stainless steel fibers to refractory concrete can significantly enhance its thermal shock resistance, crack resistance, and overall mechanical properties. Melt extract stainless steel fibers are manufactured through a process called melt extraction, where molten stainless steel is rapidly cooled and solidified to form thin, elongated fibers. These fibers possess excellent thermal conductivity, high tensile strength, and good corrosion resistance, making them ideal for use in refractory concrete. The addition of stainless steel fibers to refractory concrete can improve its ability to resist thermal cracking and spalling caused by rapid temperature changes. The fibers act as reinforcement, distributing the stress across the concrete matrix and preventing the formation of cracks. This enhances the durability and longevity of refractory concrete in high-temperature environments. Furthermore, stainless steel fibers can also improve the mechanical properties of refractory concrete. They increase the tensile strength and flexural strength of the concrete, making it more resistant to mechanical stress and ensuring its structural integrity even at elevated temperatures. In summary, melt extract stainless steel fiber is a suitable material for use in refractory concrete applications. Its addition can enhance the thermal shock resistance, crack resistance, and mechanical properties of refractory concrete, making it more durable and reliable in high-temperature environments.

- Q: Is melt extract stainless steel fiber compatible with all types of admixtures?

- No, melt extract stainless steel fiber may not be compatible with all types of admixtures. Compatibility depends on the specific type of admixture and its chemical composition, as well as the intended application. It is important to consult with experts or manufacturers to determine the compatibility before usage.

- Q: Can melt extract stainless steel fiber be used in precast tunnel portals?

- Yes, melt extract stainless steel fiber can be used in precast tunnel portals. The stainless steel fiber provides reinforcement and enhances the overall strength and durability of the precast concrete, making it suitable for use in tunnel portals where there may be high levels of stress and potential for cracking.

- Q: How does the addition of melt extract stainless steel fiber affect the setting time of concrete?

- The addition of melt extract stainless steel fiber can affect the setting time of concrete in a few ways. Firstly, the stainless steel fibers can act as nucleation sites for the formation of hydration products, which can accelerate the setting time of concrete. This is because the stainless steel fibers provide additional surface area for the hydration reactions to occur, leading to faster cement hydration and setting. Secondly, the stainless steel fibers can also improve the overall mechanical properties of the concrete, such as its tensile strength and crack resistance. This can indirectly affect the setting time of concrete by reducing the need for extended curing periods. With improved mechanical properties, the concrete can reach its desired strength faster, allowing for shorter setting times. However, it is important to note that the addition of melt extract stainless steel fiber should be carefully controlled to avoid any negative effects on the setting time of concrete. Excessive amounts of fibers can hinder the flowability of the concrete mixture, leading to longer setting times. Therefore, it is crucial to find the right dosage of stainless steel fibers to achieve the desired setting time and mechanical properties of the concrete. Additionally, the specific characteristics of the stainless steel fibers, such as their length and aspect ratio, can also influence the setting time of concrete and should be taken into consideration during the design and mixing process.

- Q: What is the cost-effectiveness of using melt extract stainless steel fiber in concrete?

- The cost-effectiveness of using melt extract stainless steel fiber in concrete can vary depending on various factors. Firstly, the initial cost of incorporating stainless steel fibers into concrete can be higher compared to traditional reinforcement methods such as rebar or wire mesh. Stainless steel fibers are generally more expensive to produce and purchase, which can contribute to higher upfront costs. However, the cost-effectiveness of using stainless steel fiber in concrete lies in its long-term benefits and performance. Stainless steel fibers offer excellent durability and corrosion resistance, making them suitable for applications in harsh environments or where long-term structural integrity is required. By enhancing the tensile strength and crack resistance properties of concrete, stainless steel fibers can help increase the lifespan of the concrete structure. This, in turn, can lead to reduced maintenance and repair costs over the life cycle of the structure. Moreover, the use of stainless steel fibers can also provide cost savings by eliminating or reducing the need for additional reinforcement materials, such as rebar or mesh. The fibers can distribute the load more evenly throughout the concrete, reducing the potential for localized cracks or failures. Additionally, the labor and time required for installing stainless steel fibers is often less compared to traditional reinforcement methods. This can result in cost savings during the construction phase. It is important to consider the specific project requirements and the expected lifespan of the concrete structure when evaluating the cost-effectiveness of using stainless steel fibers. While the initial costs may be higher, the long-term benefits and reduced maintenance expenses can make it a cost-effective choice in certain applications.

- Q: Can melt extract stainless steel fiber improve the fatigue resistance of concrete?

- Indeed, the fatigue resistance of concrete can be enhanced by using melt extract stainless steel fiber. To bolster the mechanical properties and durability of concrete, stainless steel fibers are commonly employed as reinforcement. By reinforcing the matrix and bolstering its capacity to endure cyclic loading and stress, the inclusion of stainless steel fibers enhances concrete's ability to resist cracking and fatigue. These fibers act as reinforcement by bridging cracks and impeding their propagation, thereby elevating the fatigue performance of concrete as a whole. Melt extract stainless steel fibers possess remarkable tensile strength and outstanding corrosion resistance, rendering them particularly effective in augmenting the fatigue resistance of concrete structures.

- Q: Is melt extract stainless steel fiber compatible with different types of aggregates?

- Yes, melt extract stainless steel fiber is compatible with different types of aggregates.

- Q: Is melt extract stainless steel fiber corrosion resistant?

- Indeed, melt extract stainless steel fiber exhibits remarkable resistance to corrosion. The presence of chromium in its composition grants stainless steel with exceptional corrosion resistance. Chromium enables the formation of a fine, protective oxide layer on the steel's surface, effectively thwarting corrosion and the development of rust. Consequently, melt extract stainless steel fiber is exceptionally well-suited for deployment in demanding environments or situations involving exposure to corrosive agents. Moreover, the fiber's corrosion resistance guarantees its longevity and durability across diverse sectors like construction, automotive, and aerospace.

- Q: How does melt extract stainless steel fiber enhance the resistance of concrete to dynamic loading?

- Melt extract stainless steel fiber enhances the resistance of concrete to dynamic loading by improving its tensile strength and ductility. The fibers act as reinforcements within the concrete matrix, distributing the load more evenly and reducing the formation and propagation of cracks. This results in a more durable and resilient concrete structure that can withstand the impact and vibrations caused by dynamic loading, such as heavy traffic, seismic activity, or machinery operations.

- Q: Does melt extract stainless steel fiber affect the electrical conductivity of concrete?

- The electrical conductivity of concrete can be affected by the use of melt extract stainless steel fiber. When stainless steel fibers are incorporated into the concrete, they have the potential to enhance its electrical conductivity. This enhancement is achieved by the creation of a conductive network within the concrete matrix, enabling the flow of electrical current. This improved electrical conductivity is particularly advantageous in situations where electrical grounding or conductivity is necessary, such as when constructing electrostatic discharge (ESD) flooring or producing conductive concrete for electromagnetic shielding. However, it is essential to consider that the actual impact on electrical conductivity will vary depending on several factors, including the quantity and distribution of the stainless steel fibers in the concrete mixture.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 200 Million |

| Main Markets | North America;Asia;Western Europe;Africa;Russia;Middle East |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 20% - 30% |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 150,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Installation guide, OEM Service Offered |

| Product Price Range | High; Average |

Send your message to us

Melt Extract Stainless Steel Fiber 446 - High Quality Melt Extract Stainless Steel Fiber

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 5000 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords