Melt Extract Stainless Steel Fiber 310 - High Quality Material

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 5000 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

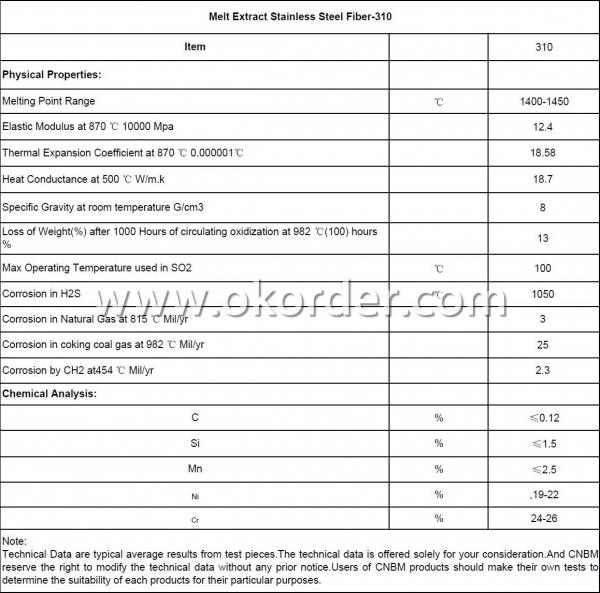

General Information of Melt Extract Stainless Steel Fiber 310

CMAX melt extract stainless steel fiber 310 is produced by melting elements in a crucible packing by paper boxes. A flywheel is then introduced to the crucible and droplets of molten metal are spun into the open air and hardened. CMAX melt extract stainless steel fibers are spun directly from the melt using the company's advanced Melt Extraction (ME) and Melt Overflow (MO) processes. CMAX melt extract stainless steel fiber can increase the lifetime of refractory materials and industrial furnaces by several times, decreasing cost and saving labor costs.

CMAX Melt Extract Stainless Steel Fiber 310 exhibits the following characteristics:

Improve refractories’ performance

Improve refractories’ longevity

Improve refractories’ durability

Significantly reducing downtime and maintance cost

CMAX Melt Extract Stainless Steel Fiberis 310 available in a wide variety of application:

CMAX Melt Extract Stainless Steel Fiberis 310 available in a wide variety of application:

Refractory products

Precast

Castable project

Industrial furnaces

Other refractories project

Our company has success in its melt extract stainless steel fiberproducts due to their cost-effectiveness and excellent insulating properties. We also have experience in melt extract stainless steel fiberapplication and would like to assist you in product selection, system design, and installation techniques. Our products of melt extract stainless steel fiber are in good quality and in best price and we are looking forward for your enquiry.

- Q: Can melt extract stainless steel fiber be used in the construction of cooling towers?

- Yes, melt extract stainless steel fiber can be used in the construction of cooling towers. Cooling towers are typically exposed to harsh environments, including high temperatures and corrosive chemicals. Stainless steel fibers have excellent resistance to corrosion and high temperatures, making them suitable for such applications. These fibers can be used to reinforce the concrete used in the construction of cooling towers, enhancing their mechanical properties and durability. Additionally, stainless steel fibers can improve the crack resistance and prevent the propagation of cracks in the concrete, ensuring the structural integrity of the cooling tower. Overall, using melt extract stainless steel fiber in the construction of cooling towers can enhance their performance, longevity, and resistance to corrosion and high temperatures.

- Q: Can melt extract stainless steel fiber be used in fiber-reinforced polymer (FRP) concrete mixtures?

- Indeed, fiber-reinforced polymer (FRP) concrete mixtures can incorporate melt extract stainless steel fiber. Renowned for their exceptional tensile strength, resistance to corrosion, and lasting performance, melt extract stainless steel fibers prove ideal for reinforcing concrete mixtures, including FRP concrete. Integrating stainless steel fibers into FRP concrete augments its structural integrity, bolsters crack resistance, and heightens both flexural and tensile strength. Moreover, the utilization of stainless steel fibers further promotes the overall sustainability and longevity of FRP concrete structures.

- Q: What is the recommended fiber geometry for melt extract stainless steel fiber in concrete?

- The recommended fiber geometry for melt extract stainless steel fiber in concrete is typically in the form of straight, monofilament fibers. These fibers are usually slender and have a diameter ranging from 0.15 mm to 0.50 mm. The length of the fibers can vary, but it is often recommended to use fibers with lengths between 20 mm to 50 mm for optimal performance in concrete. The use of straight, monofilament fibers offers several advantages in concrete applications. Firstly, these fibers provide excellent bonding with the surrounding concrete matrix, enhancing the overall mechanical properties of the material. Secondly, the straight geometry allows for effective dispersion and distribution of the fibers throughout the concrete, ensuring uniform reinforcement and improved crack control. Additionally, the slender diameter of the fibers allows for easier mixing and placement of the concrete, without significantly affecting the workability of the mixture. It is important to note that the specific fiber geometry may vary depending on the desired performance requirements and the specific application of the concrete. Therefore, it is recommended to consult with manufacturers or experts in the field to determine the most suitable fiber geometry for a particular project.

- Q: How does melt extract stainless steel fiber improve the resistance to spalling in shotcrete?

- Melt extract stainless steel fiber enhances the resistance to spalling in shotcrete by reinforcing the concrete matrix. The fibers are dispersed uniformly throughout the shotcrete, creating a three-dimensional network that improves the overall strength and durability of the material. This reinforcement reduces the formation and propagation of cracks, thereby minimizing the risk of spalling under various loading conditions. Additionally, the stainless steel fibers act as a barrier to inhibit the ingress of moisture and other aggressive substances that can contribute to spalling.

- Q: How does melt extract stainless steel fiber affect the carbonation resistance of concrete?

- Melt extract stainless steel fiber can significantly enhance the carbonation resistance of concrete. Carbonation is a chemical process where carbon dioxide from the atmosphere reacts with the calcium hydroxide in concrete to form calcium carbonate. This process can lead to a reduction in the alkalinity of the concrete, which in turn can result in the corrosion of embedded reinforcement and a decrease in the overall durability of the structure. By incorporating melt extract stainless steel fiber into concrete, it creates a three-dimensional reinforcement network that helps to improve the mechanical properties and durability of the concrete. The stainless steel fibers act as a physical barrier, reducing the ingress of carbon dioxide into the concrete matrix. This barrier effect slows down the carbonation process, effectively increasing the carbonation resistance of the concrete. Additionally, the stainless steel fibers also enhance the overall mechanical properties of the concrete, making it more resistant to cracking and spalling. This increased resistance to cracking further reduces the potential for carbon dioxide to penetrate the concrete, as cracks provide pathways for gas diffusion. Furthermore, the stainless steel fibers can also help to mitigate the effects of carbonation by providing an additional level of corrosion protection to the embedded reinforcement. The fibers act as sacrificial anodes, diverting any potential corrosion initiation sites away from the reinforcement and onto themselves. This sacrificial anode effect helps to prolong the service life of the concrete structure by reducing the risk of reinforcement corrosion due to carbonation. In summary, melt extract stainless steel fiber positively affects the carbonation resistance of concrete by acting as a physical barrier, enhancing mechanical properties, and providing additional corrosion protection to the embedded reinforcement. These benefits contribute to increased durability and extended service life of concrete structures in carbonation-prone environments.

- Q: What is the effect of melt extract stainless steel fiber on the plastic shrinkage of concrete?

- The effect of melt extract stainless steel fiber on the plastic shrinkage of concrete is that it helps reduce the occurrence of plastic shrinkage cracking. The fibers act as reinforcement within the concrete, improving its overall tensile strength and reducing the potential for shrinkage-related cracks. Additionally, the stainless steel fibers help to distribute stress more evenly throughout the concrete, minimizing the formation of shrinkage cracks caused by drying shrinkage.

- Q: Is melt extract stainless steel fiber compatible with all types of concrete additives?

- Melt extract stainless steel fiber is generally compatible with most types of concrete additives. However, it is important to check the specific compatibility of the fiber with the additives being used in your concrete mixture. Some concrete additives, such as certain accelerators or superplasticizers, may have adverse reactions with stainless steel fibers. It is recommended to consult with the manufacturer or supplier of the stainless steel fiber and the concrete additives to ensure compatibility before using them together in your concrete mixture.

- Q: Can melt extract stainless steel fiber improve the bond strength of concrete to epoxy coatings?

- The use of melt extract stainless steel fiber is effective in enhancing the bond strength between concrete and epoxy coatings. Stainless steel fibers are frequently employed as reinforcement in concrete to increase its tensile strength and durability. Once incorporated into concrete, these fibers aid in the distribution and dissipation of stress, thereby minimizing crack formation and enhancing the overall structural integrity. In the context of epoxy coatings, the inclusion of melt extract stainless steel fibers offers numerous advantages. Firstly, these fibers serve as mechanical anchors, improving the bond between the concrete and the epoxy coating. This enhanced bond strength ensures that the coating remains securely attached to the concrete surface, even when subjected to stress or movement. Secondly, the presence of stainless steel fibers also helps in reducing crack formation within the epoxy coating. By reinforcing the concrete substrate, these fibers distribute any stress or load applied to the coating more evenly, thus reducing the likelihood of crack formation due to localized stress concentrations. Moreover, melt extract stainless steel fibers contribute to the overall durability and lifespan of the epoxy coating. They provide added protection against impact, abrasion, and other forms of wear and tear that the coating may experience over time. This increased durability results in epoxy coatings that are longer-lasting and more resilient. In conclusion, the addition of melt extract stainless steel fiber significantly improves the bond strength between concrete and epoxy coatings. By enhancing the mechanical connection and providing additional reinforcement, these fibers contribute to a stronger, more durable, and longer-lasting bond.

- Q: Can melt extract stainless steel fiber be used in the construction of offshore platforms?

- Melt extract stainless steel fiber is indeed a viable option for the construction of offshore platforms. This material possesses exceptional strength and outstanding resistance to corrosion, which makes it highly suitable for marine environments like offshore platforms. By incorporating it into concrete reinforcement, the structural integrity and durability of the platform can be greatly enhanced. The stainless steel fiber's capacity to withstand harsh conditions, such as exposure to saltwater, ensures the long-lasting and robust nature of the offshore platform. Moreover, utilizing stainless steel fiber can aid in minimizing the expenses related to maintenance and repair caused by corrosion damage, thus establishing it as an ideal choice for constructing offshore platforms.

- Q: Can melt extract stainless steel fiber be used in pre-stressed concrete?

- Yes, melt extract stainless steel fiber can be used in pre-stressed concrete. The addition of stainless steel fibers in pre-stressed concrete can provide increased ductility and crack resistance, enhancing the overall performance and durability of the concrete structure. The stainless steel fibers act as reinforcement by dispersing the stress and preventing the propagation of cracks. This helps to improve the structural integrity of the pre-stressed concrete and increases its resistance to mechanical and environmental stresses. Additionally, the use of melt extract stainless steel fibers in pre-stressed concrete can also contribute to reducing the potential for corrosion, as stainless steel is highly resistant to rust and other forms of degradation. Overall, the incorporation of melt extract stainless steel fibers in pre-stressed concrete can improve its strength, flexibility, and longevity.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 60 Million |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 31% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 36,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Melt Extract Stainless Steel Fiber 310 - High Quality Material

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 5000 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords