Matte Wood Grain Film For Decoration Using

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Application of Matte Wood Grain Decorative Film:

Matte Wood Grain Decorative Film for Decoration covered by vacuum/membrane press/laminating machine on the surface of various boards, such as MDF, veneer boards, flake boards, fiberboards, block boards and other materials of high-pressure floor slabs, asbestos boards, slates, aluminum and plastic profiles. Matte Wood Grain Decorative Film are widely used for indoor decoration and furniture making industry.

2.Main Features of Matte Wood Grain Decorative Film:

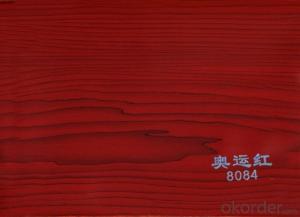

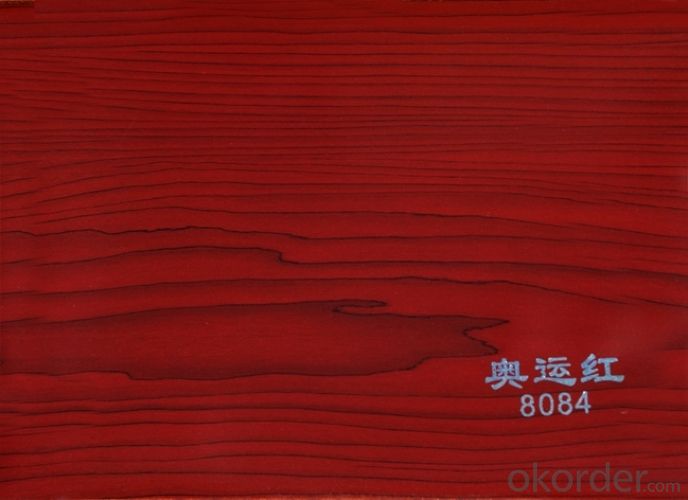

Different models and various kinds of style

Sparkle silver and wood grains are available

Easy cleaning

Eco Friendly

Exquisite color, high saturation, environmentally-friendly, waterproof, unfading,acid and alkali resistant.

3. Matte Wood Grain Decorative Film Images:

4. Matte Wood Grain Decorative Film Specification:

Thickness from 0.12mm to 0.60mm

Length: 100-500m/roll

Width: 200-1,575mm

5. FAQ of Matte Wood Grain Decorative Film:

We have organized several common questions for our clients, may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of PVC decorative sheet is a new kind of environmental protection material, it has strong sense of grain simulation, waterproof, acid and alkali resistant, fire from self quenching characteristics, because it will not fade, so the construction without paint, convenient operation, which shortens the construction period and reduce the cost, especially without paint pollution gas.

2) What is the storage condition?

The welded wire mesh should be stored at room temperature and kept from wet and heat source.

3) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4) How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: The introduction of protective film

- Protective film can be made from materials like PET and AR. There are many types of protective films. And the film can be used on many items including the screen of mobile phone and stainless steel.

- Q: What kind of material is acrylic protective film made from?

- Acrylic protective film can be made from PE materials, PET materials and OPP materials, etc. The materials are the materials used in base film of the protective film. And acrylic is a kind of glue.

- Q: Can the TP protection screen prevent the screen from being broken?

- The toughened glass protective film can be affixed to the screen.The toughened glass protective film can be affixed to the screen.

- Q: What to do when the protective film of Bayer sunlight plate cannot be torn?

- Return the goods to the manufacturers and require them to exchange. It's the common sense about protective films.

- Q: Performance index of PE protective film

- Purpose: tack stability, good adhesion, then peeling performance is good, no glue residue phenomenon for furniture Polaroid plate, stainless steel plate, ceramic tile, marble, artificial stone and so on.4. medium adhesive filmCharacteristics: thick (0.05 + 0.003), width (less than 1.3), high (100-1000), substrate (PE), peel strength (60-80g/cm), temperature (60), stretching rate (>400)Usage: sticky, stable, good adhesion, good peeling performance, no residual glue phenomenon, apply to fine lines, grinding board and general difficult to stick material surface protection, etc.5. high viscosity protective filmCharacteristics: thick (0.05 + 0.003), width (less than 1.3), high (100-800), substrate (PE), peel strength (80-100g/cm), temperature (60), stretching rate (>400)Uses: sticky, stable, good adhesion, and then good peeling performance, no residual glue phenomenon, applicable to fine lines, matte board, aluminum plate, difficult to stick plastic plates6. super high viscosity protective filmCharacteristics: thick (0.04 + 0.003), width (less than 1.3), high (100-800), substrate (PE), peel strength (more than 100g/cm), temperature (60), stretching rate (>400)Uses: high viscosity, use water-based acrylic as pressure-sensitive adhesive, easy to use, easy to paste, easy to tear, no residual glue phenomenon. Suitable for coarse lines, aluminum and other difficult to sticky material

- Q: How to clean up the protective film on the stainless steel door! ! !

- Many people have the same question. The protective film on the stainless steel door is difficult to remove after using fot a long time. Does it work to heat the film with electric hair drier? Is there any other ways? The answer is yes. There are many other ways: 1. If the film is not too big, you can apply some lacquer thinner to it and then scrub it with cleaning ball. 2. Detergent used in textile industry will work (Bottled such detergent is called AL). I've tried it. It really works well. 3. Use sulfuric acid. But you should mix it with water before use, otherwise the door will corrode. Immerge the door into the mixed sulfuric acid for a period of time and scrub it with cleaning ball. 4. Firstly, use electric hair drier to heat the film. And then slowly tear it off or scratch it off using small wooden shovel. The marks left by glue can be wiped off with solvent.

- Q: What's the function of the protective film coated on cup lid?

- It's used to prevent the lid from scratches during delivery. It is not necessary to pay attention to these details.

- Q: What are the differences between PE protective film, PET protective film and PVC protective film?

- PE refers to polyethylene. It's commonly used in protective films, featuring low price, softness, excellent ductility and environmental friendliness. Generally speaking, products made from this kind of material must pass the ROHS environmental pollution tests stipulated by European Union. Its disadvantage is poor whether resistance. It's not suitable to be used at temperature more than 60℃. PVC refers to polyvinyl chloride. Its features are good softness and whether resistance. And its disadvantage is non-environmental-friendly. Thus many big international brands rarely use this kind of material. Products made from this kind of material are mainly used for anti-static protection or as the surface of wooden stereo. PET refers to polyester. Its major property is good whether resistance which makes it resistant to high temperature of 100℃ to 150℃, hardness and flatness. And its disadvantage is that it can't be used on angular products.It's mainly used in die cutting.

- Q: Do I need to tear off the protective film on the two sides of the refrigerator?

- Of course you should tear it off.

- Q: Can TP protective film keep screen from breaking?

- Explosion-proof membrane is ok ~

Send your message to us

Matte Wood Grain Film For Decoration Using

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords