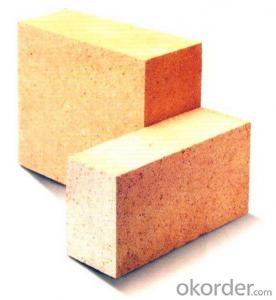

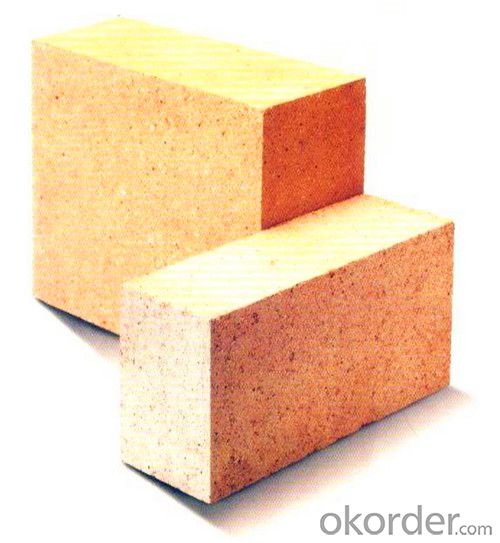

High Alumina Brick for Low Creeping Rate Cement Kiln Thin Brick Interior Walls

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1044 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

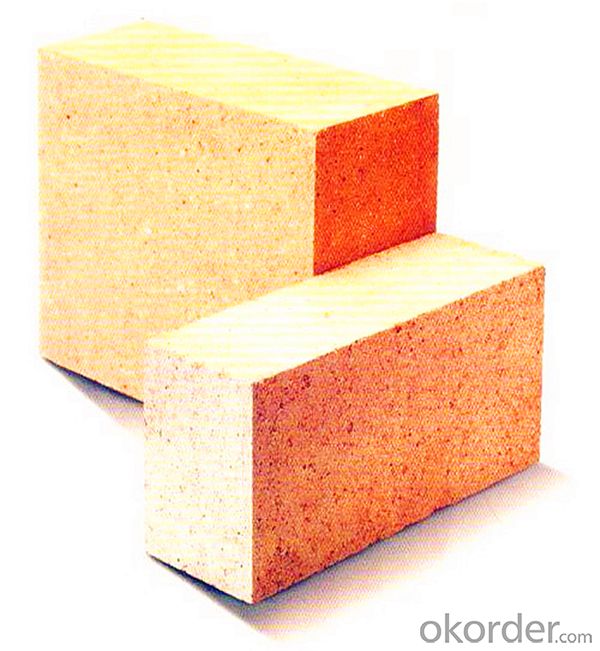

Low Creeping Rate for Cement Kiln Thin Brick Interior Walls

Product Description

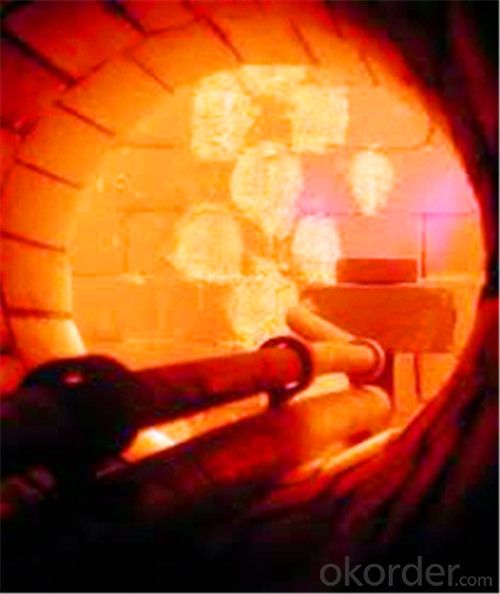

The phosphate bonded high aluminum bricks are with high strength, low bulk density, low thermal, conductivity, high thermal shock resistance and the anti-spalling is good. Widely used in cement kiln,hot blast stove/furnace,EAF(electric arc furnace),coke oven door...

Structure& Advantage

for Our High Aluminum/Alumina Refractory Brick, Fireclay Bricks

1) Good thermal shock resistance

2) High-temperature endurable

3) Good thermal insulation

4) The using temperature is 1600 c

5) Phosphate high alumina bricks,iso

6) High strength

7) Low thermal conductivity

8) Widely used in cement kiln.

9) Low creeping rate

10) High pressure

11) Excellent thermal shock resistance

12) High quality fireclay clinker

We Are Suppiler for

Below are some of our customers

Allied Mineral Products,inc

Refractories Incorporated

Srs Sorg Refractory Systems GmbH,

Sunward Refractories Co.,Ltd

Lilama69-1 Joint Stock Company etc.

Major Images

Refractory High Alumium and Fireclay Brick

Specification for High Aluminum Refractory Brick

ITEM | UAL48 | UAL55 | UAL65 | UAL75 | UAL80 | UAL85 | ALP80 |

Refractoriness, ℃ | 1750 | 1770 | 1790 | 1790 | 1810 | 1810 | 1810 |

Apparent Porosity,% | 22 | 22 | 23 | 23 | 20 | 20 | 18 |

C.C.S, Mpa | 39 | 44 | 49 | 53 | 55 | 60 | 100 |

Refractories Under Load (0.2Mpa),℃ | 1420 | 1470 | 1500 | 1520 | 1500 | 1520 | 1550 |

Reheating Linear Change,% | 1450x2h 0.1~-0.4 | 1500x2h 0.1~-0.4 | 1500x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1550x2h -0.5~+0.5 | 1550x2h -0.5~+0.5 | 1550x2h -0.5~+0.5 |

Al2O3 Content , % | 48 | 55 | 65 | 75 | 80 | 85 | 82 |

FAQ

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories, at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time, seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C are available for us.

Q5:After an order is confirmed, when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q8:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q9:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q10:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

- Q: What are the high aluminum bricks made of?

- The amount of refractory mud accounts for about 6% of the brick weight

- Q: What are the main components of high alumina bricks?

- Sweat is like water mineral alumina bauxite, aluminum ore, magnesite, waves of gibbsite. Anhydrous alumina raw material, such as corundum, alumina, fused corundum. High alumina brick Zhengzhou gold company specializing in the production of various specifications, you can directly ask their technical staff.

- Q: What are the grades of high alumina bricks?

- High alumina brick according to the aluminum content is generally divided into: super high alumina brick, a high aluminum brick, two high alumina brick, three high alumina brick

- Q: What refractory material does cupola lining use?

- Materials defined as physical and chemical properties that allow them to be used in a high temperature environment are called refractory materials. Refractory materials are widely used in metallurgy, chemical, petroleum, machinery manufacturing, silicate, power and other industrial fields, the largest amount of metallurgical industry, accounting for 50% ~ 60% of the total output.

- Q: What materials are used for roof insulation?

- There are two kinds: one is a kind of cotton insulation board, such as rock wool board, aluminum silicate cotton board, but this is not environmental protection, harmful to life, foam board (this fire safety factor minimum), these relatively cheap.

- Q: Which is better, the soft core or the hard core?

- The use of each of the single core copper wire with low line, 1.5 square with cap line home, socket 2.5 square, air conditioning to walk alone line 4 square can, when the terminal box into a socket with leakage protection switch, prevent overload and short circuit.

- Q: Corundum, high alumina and fireclay refractory difference is what

- Corundum is unknown. The high alumina brick has higher aluminum content than the clay brick, and the temperature resistance is higher than 300 degrees. It is more durable and durable than the clay brick. The production process of high alumina brick is better than that of clay brick. For example, the weight of good clay brick is 3.7kg, and that of high alumina is 4.2kg. Good density. But the price of high aluminum is too high: ordinary clay brick (standard brick example) in 1.1--2.5 yuan / block, high aluminum to 4.5 yuan / block, or even more expensive. The extra high aluminum has reached 5000 tons. Say straight white point is: under the same conditions, clay brick for a period of one year, then the high aluminum for more than three years.

- Q: Refractory brick, high alumina brick, magnesia chrome brick, magnesia brick, clay brick, which type of high temperature refractory brick?

- The super high alumina brick in high alumina refractory brick has the highest refractoriness, and the corresponding production cost is higher.

- Q: Is glass wool inorganic thermal insulation material?

- Yes, glass wool belongs to one kind of glass fiber. It is a kind of man-made inorganic fiber. Therefore, in the field of thermal insulation materials classified as inorganic insulation materials.

- Q: High alumina brick 80 with which high aluminum cement?

- In order to maintain a reasonable comprehensive lining, should adopt high quality aluminum refractory mud, such as Sichuan resistance card phosphate refractory mud, refractory clay, high alumina refractory mud PA-80 LN-75, if you use the card volume of Sichuan resistant refractory clay masonry, the effect is better.

Send your message to us

High Alumina Brick for Low Creeping Rate Cement Kiln Thin Brick Interior Walls

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1044 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords