Eco-Friendly Ceiling Profile Lightgage Steel Joist 75Stud

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

Specifications

Used for wall partition

High intensity and toughness

Easy installation

1)Size:

QC 75×45×0.6

QC 75×45×0.7

QC 75×45×0.8

QC 75×45×1.0

2)Features:

(A)light-weight, long lifetime, high durability and rust resistance.

(B)Easy be cut apart, convenience in stallation, environment friendly.

3) Application:

Interior partition wall or veneering wall of hotels, theaters, emporiums, factories,

office, house, airplane-terminal buildings, bus stations, waiting lounge, etc.

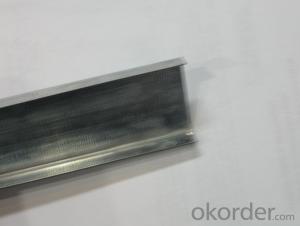

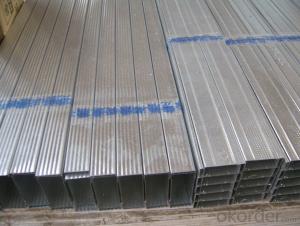

3.Image

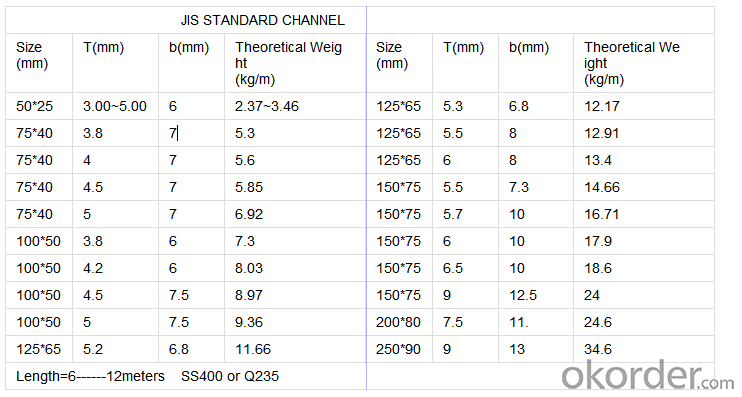

4.Detailed Specification

5.FAQ

Fundamental functions of cold roll forming machine

The adjustable and speed changeable equipment is used to roll various kinds of profile materials. It uses decelerator to transmit each gear case in the main machine. The upper and lower two universal rotational axes on each channel drive each roller in arch frame to roll shaping. The number of forming lines is decided on the demand of sectional design or clients'. The line is equipped with automatic feeder and guide feeder. Adopting hydraulic pressure or pneumatic to realize automatic tracking cutting and unloading. It also adopted arbitrarily scale structural section of material receiving station and electric control system with synchronized movement.

Above-mentioned is our factory’s cold roll forming machine which has been manufactured. In this field, our factory has accumulated a great quality of equipments and mould materials. In no exceptional circumstances, our company can give you one package service including comprehensive technology, quality assurance, and reasonable price, finishing designing, creating, debugging and after-sale service. We are willing to deliberative discuss and cooperate with you about the exploitation of the varieties of profile steel. We are earnestly welcome you to our factory to have a field trip, we can offer you all kinds of product introduction and equipments technical reference.

Thickness: 0.15mm - 4.00mm

coil Width: 11mm-1500mm

Zinc coating: Z80 - Z275/m2

CID: 508 or 610mm

Standard: EN, JIS, GB

Grade: DX51D, SGCC, Cs-B, S280, S320, S350, S380, DQ, DDQ, Q195

Skinpassed: If required

Surface processing: Regular spangle, Minimized spangle, Zero spangle, bright spangle

Surface chemical processing: Chromate, un-chromate passivation and fingerprint resistant treatment;

slight oiled or non-oiled

- Q: Will the light steel keel ceiling area is small can be no boom?

- Do not meet, must be installed boom, side keel fixed must be,

- Q: Light steel keel ceiling hanging bar spacing how much?

- 30 cm to 40 cm between

- Q: Light steel keel gypsum board ceiling need floor?

- Owners have money to do the second floor

- Q: Light steel keel ceiling steps? How to use wood?

- You should also have a lantern with a lantern. The board is the lantern

- Q: What is a man ceiling, what is not a man ceiling?

- My idea is that the master name suggests, you can master, ask the high point of the tune, the keel to meet the requirements of the Master, and now sell the keel is not on the Master and Master, keel easy to repair, Learn from everyone

- Q: Is in accordance with the vice keel 400, the main dragon spacing 600 spacing arrangement?

- Light steel keel ceiling 400 * 600 meaning: the main keel and the distance between the main keel 600MM, vice keel and vice keel spacing of 400MM. Light steel keel ceiling, is that we often see the ceiling, especially the shape of the ceiling, are made of light steel keel frame, and then covered with gypsum board made. Light steel keel ceiling according to load is divided into human light steel keel ceiling and not on the light steel keel ceiling. Light steel keel according to keel section can be divided into: U-keel and C-keel. According to specifications can be divided into: D60 series, D50 series, D38 series, D25 series. Light steel keel, is a new type of building materials, with the development of China's modernization drive, light steel keel is widely used in hotels, terminals, bus stations, stations, playgrounds, shopping malls, factories, office buildings, old buildings Building renovation, interior decoration, roof and other places. Light steel (paint) keel ceiling with light weight, high strength, to adapt to water, shock, dust, noise, sound absorption, constant temperature and other effects, but also has a short duration, easy construction and so on.

- Q: Consultation: What is the keel of the living room ceiling?

- Hello, now are generally used light steel keel Oh.

- Q: Ceiling twenty square meters need light steel keel how many roots

- Light steel keel ceiling material ratio does not have a standard number, generally according to the shape of the room, height related.

- Q: Light steel keel good or fir Fang Fang dragon skeleton good

- Wood keel selection points: 1, fresh wood keel slightly red, texture clear, if its color is dark yellow, matte description is rotten wood. 2, to see whether the selected wooden cross-section specifications meet the requirements, head and tail is smooth and uniform, not the size of different. At the same time wood keel must be straight, not straight wood keel easily lead to structural deformation. 3, to choose the wood scar festival less, smaller wood keel, if the wood scar large and more, screws, nails in the wood scars will not screw into the line or broken off the wooden side, easily lead to the structure is not strong. 4, to choose the density, deep wood keel, you can use the fingernail to pull to see, good wood keel will not have obvious traces.

- Q: Ceiling with light steel keel size is generally how much

- Wall steel ceiling keel specifications and information decoration materials Light steel keel wall materials are 50, 75, 100, 150 and several other Light steel keel thickness ranging from 0.4mm to 2.0mm.

Send your message to us

Eco-Friendly Ceiling Profile Lightgage Steel Joist 75Stud

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords