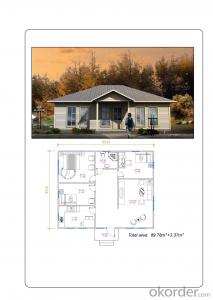

light steel structures prefab house for plant

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

light steel structures prefab house for plant

1. Lightweight for easy handling & economical shipping.

Because steel construction components’ weight is about 2/3 less than wood components, the average 200 square meter house requires only about 6 tons of steel for framing components and 20 tons of lumber. The structure applies to residential roofing, where steel profiles weigh much less than slate, composite tile, and wood cedar shake.

2. Strength that only steel can

No other construction material can match steel’s superior strength and durability. In fact, steel’s strength allows homes to be designed with larger open spaces.

3. Precise measurements, perfect angles.

Steel construction components can be precut and pre-measured to exact specifications. On-site adjustments aren’t required. Even standard lengths require only minimal cutting.

4. Resistant to termites and pest.

Steel is simply impervious by termites and other borers causing bugs and pests. Owners can look forward to a lifetime of pest-prevention convenience.

5. Won’t rot, chip, splinter, crack, split or warp. Ever.

Steel framing stays straight and true. And unlike wood, steel holds walls straight without any shifting or twisting. Even steel roof profiles are virtually maintenance-free.

6. Withstands the worst environmental conditions.

Strong and noncombustible, steel provides great protection against the worst conditions including fire, floods, snow buildup, intense sun and high humidity. Steel can even provide protection against hurricanes and earthquakes.

7. Insurance companies love steel.

Because steel is noncombustible and termite-proof, it qualifies for what insurance companies call “superior construction”. So premiums are typically lower.

8. Steel components mean minimal material waste.

Cut-to-length steel framing generates almost no material waste. Steel roofing ,may be applied over existing roofs, eliminating tear off waste for landfill.

9. Installation is fast and simple. Labor costs are minimal.

Steel framing is lightweight and precut to desired lengths while steel roofs can be installed in long lengths. Construction goes quickly and easily. Crews can do more work in less time.

10. Every inch of steel is recyclable.

Unlike wood, which uses up our natural resource of tree, steel is an excellent choice for environmentally sound home construction, All steel construction components, even scraps, are completely recyclable.

11. Cost effective from start to finish.

Compared to traditional construction materials, steel framing and roofing offer significant cost advantages. Material costs are competitive and more consistent. Shipping is more economical. Labor is more cost-effective. Insurance premiums may be lower. And properly installed, energy efficiency is better.

Need more reasons? Please Contact us.

- Q: Are container houses suitable for low-income housing projects?

- Yes, container houses can be a suitable option for low-income housing projects. Container houses are cost-effective as they utilize recycled shipping containers, which significantly reduces construction costs. These projects can be implemented quickly and efficiently, allowing for a faster turnaround time to accommodate the urgent need for low-income housing. Additionally, container houses are flexible and can be easily modified to meet the specific needs and requirements of different communities. They can be designed to include essential amenities such as plumbing, electricity, and insulation, providing a safe and comfortable living environment for low-income individuals and families. Furthermore, container houses are environmentally friendly as they promote sustainable living by repurposing existing materials. Overall, container houses offer an affordable and practical solution for low-income housing projects, making them a suitable choice for addressing the housing needs of disadvantaged communities.

- Q: Can container houses be designed to have a large outdoor living area?

- Yes, container houses can be designed to have a large outdoor living area. While container houses are typically smaller in size compared to traditional houses, they can still provide ample outdoor space if designed and planned properly. One common approach is to combine multiple containers or extend the living area by adding additional structures such as decks, patios, or pergolas. By strategically stacking or arranging containers, architects and designers can create open and spacious outdoor areas. This can be achieved by removing one or more sides of the container to create an open space that seamlessly connects the indoor and outdoor areas. Additionally, containers can be modified to include sliding or folding doors that can be completely opened up to expand the living space outdoors. Furthermore, container houses can incorporate various outdoor features to enhance the overall living experience. These may include landscaping elements such as gardens, lawn spaces, or even swimming pools. By carefully considering the layout, orientation, and placement of the containers, it is possible to maximize the available outdoor space and create a large and comfortable outdoor living area. Ultimately, the design possibilities for container houses are limited only by creativity and budget. With thoughtful planning and design, container houses can indeed offer a large outdoor living area, providing homeowners with the opportunity to enjoy the outdoors while living in a unique and sustainable dwelling.

- Q: Are container houses resistant to snow or heavy snowfall?

- Yes, container houses are generally resistant to snow or heavy snowfall. The structural integrity of container houses, combined with their durable materials, allows them to withstand the weight and pressure of snow. Additionally, the compact design of container houses helps to minimize the accumulation of snow on the roof, reducing the risk of any structural damage.

- Q: Can container houses be designed to have a small ecological footprint?

- Yes, container houses can be designed to have a small ecological footprint. These houses are often built using recycled shipping containers, reducing the demand for new construction materials. Additionally, container houses can incorporate eco-friendly features such as energy-efficient insulation, solar panels, rainwater harvesting systems, and greywater recycling. By employing sustainable design principles and utilizing renewable energy sources, container houses can minimize their environmental impact and contribute to a greener future.

- Q: Can container houses be designed with a wheelchair lift?

- Certainly, wheelchair lifts can be unquestionably incorporated into the design of container houses. The remarkable flexibility and adjustability of container houses enable them to cater to diverse accessibility requirements. To ensure accessibility for individuals with limited mobility, a wheelchair lift can be seamlessly integrated into the structure of a container house. The installation of these lifts can be either internal or external, depending on the homeowner's particular preferences and needs. By meticulously considering the wheelchair lift's dimensions and weight capacity during the initial design process, container houses can be developed to be entirely inclusive and accessible for wheelchair users.

- Q: Are container houses suitable for sports facilities or training centers?

- Sports facilities and training centers can indeed benefit from the use of container houses. The versatility and adaptability of these houses are key advantages. They can be easily modified and customized to meet the specific requirements of such facilities. Container houses can be designed to provide ample space for a range of activities, including indoor gyms, fitness studios, and sports courts. The modular nature of container houses allows for easy expansion or reduction of space as needed. This enables the creation of separate areas for different sports or training activities within a single facility. Furthermore, container houses can be equipped with all the necessary amenities and equipment for sports and training purposes. Showers, locker rooms, and storage spaces can all be incorporated. Suitable ventilation and climate control systems can also be installed to ensure a comfortable environment for athletes and trainees. Additionally, container houses are built to be durable and weather-resistant, making them suitable for outdoor sports facilities. They can withstand harsh weather conditions and provide a secure and sturdy structure for sports activities. From a practical perspective, container houses offer cost-effective and time-efficient solutions for sports facilities or training centers. They are relatively affordable compared to traditional construction methods, and their construction and installation can be completed in a shorter timeframe. This makes them particularly suitable for temporary or mobile sports facilities, such as training camps or events. In conclusion, container houses are a viable option for sports facilities or training centers. Their versatility, adaptability, durability, and cost-effectiveness make them an appealing choice for creating functional and practical spaces for various sports and training activities.

- Q: Can container houses be used for temporary housing solutions?

- Yes, container houses can be used for temporary housing solutions. They are portable, cost-effective, and can be easily transported and installed in various locations. Container houses provide a quick and convenient solution for temporary housing needs such as disaster relief efforts, construction projects, or temporary accommodation during events or festivals.

- Q: Can container houses be soundproofed for privacy?

- Yes, container houses can be soundproofed for privacy. There are various techniques and materials available to reduce noise transmission, such as using insulation, double-glazed windows, and sound-absorbing panels. By implementing these solutions, container houses can effectively minimize sound transfer and provide a private and quiet living environment.

- Q: What are the characteristics and requirements of villa property management?

- for the property customer service staff and engineering staff in the provision of services for the owners must be more standardized for the owners What is urgent?

- Q: Can container houses be expanded or modified?

- Container houses have the ability to be expanded and modified. The modular design of these houses makes it easy to expand or modify the structure. It is possible to add additional containers to increase living space, or rearrange walls within the containers to create larger rooms or open floor plans. Moreover, container houses can be stacked vertically to form multi-level structures. Furthermore, it is possible to customize the exterior and interior of these houses by adding windows, doors, insulation, plumbing, electricity, and various design elements to meet specific needs and preferences. In summary, container houses offer great flexibility for expansion and modification, which makes them a versatile housing option.

Send your message to us

light steel structures prefab house for plant

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords