Large Size Metal Seal Three Eccentric Industrial Butterfly ValveDN1600

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

API Standard Metal Seat Three Eccentric Flange Butterfly Valve

The Butterfly Valve Standard

Designed: API609, ASME B 16.34,AWWA C 504, BS EN593

Face to Face: API 609,AWWAC504, BS2080, and ISO5752

Flange End: ASME B 16.5, ASMEB 16.47, BS EN1092, ISO7005

Inspection Test: API 598, BSEN 12266, ISO 528

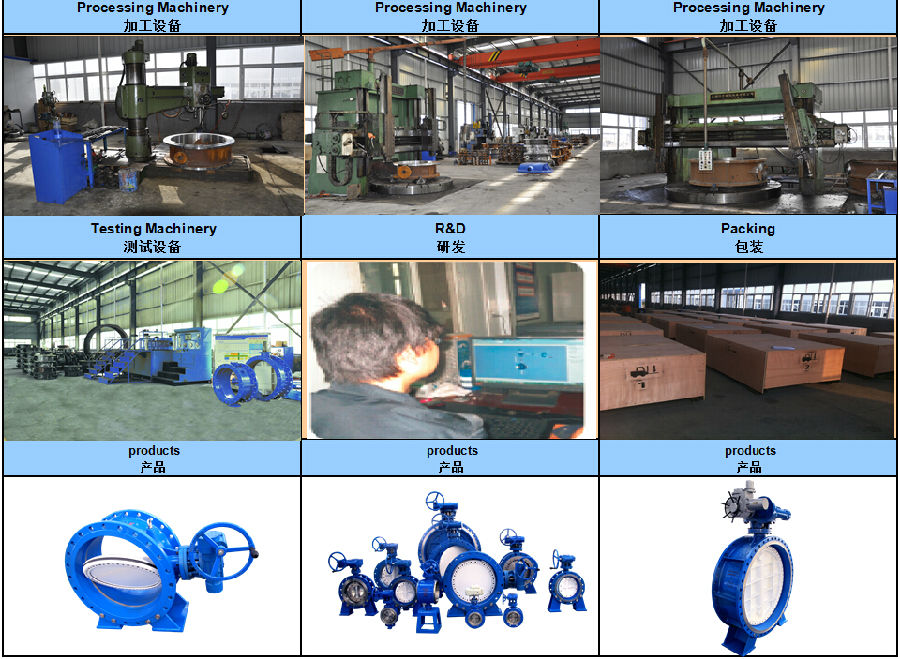

Materials Choose

Body Materials:WCB/WCC/LCB/QT450-10/QT500-7/CF8M/CF3M

Disc Materials:WCB/WCC/LCB/QT450-10/QT500-7/CF8M/CF3M

SeatMaterials:304/316/Graphite/Asbetos/PTFE

Specifications

Pressure:PN10/PN16/PN25/CL150/CL300

Size: DN40---DN3200

Drive Mode: Manual/Wormgear/Electric/Pneumatic

Field of Application: Electric/Hydraulic/Municipal Engineering etc; Water/Sea water/Gas etc.

Deliveryand Packing Terms

Delivery:within 15-30days after receipt of at sight L/C or 30% as advance payment by T/T

ButterflyValve Packing: Seaworthy packing:

1. SingleButterfly Valve is packed with foam plastic bag.

2. Putsponge in each floor

3.Electric or pneumatic actors will Individual packaging it with wood box.

4. ExportWooden Packing

5. We canpack according to specific customer requests.

6.Customers’ logos are available on package.

7. Designand manufacturing the wood box to save the sea cost if needed .

What can we do for you?

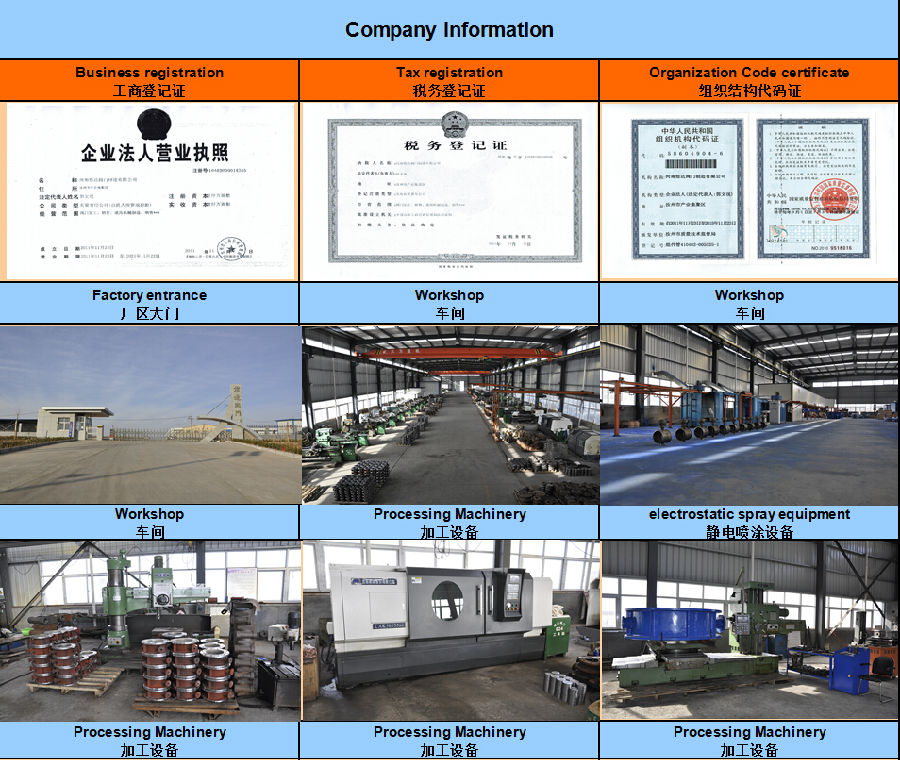

1. Save lots of your cost. As you know, more than 85% butterfly valvesare made from Tianjin in China, our factory is located in this most advantageplace too.

2. Your OEM orders are welcomed. We have own foundry, serve OEM customersfrom more than 23 coun tries.

3. Each valve is taken for two times pressure test before leavefactory! Each butterfly valve has 24 months guarantee period.

4. You’ll never be low on supply---with our monthly capacity of 32000sets.

5. More than 40 salesmen are always working with you and listening toyou.

- Q: What do you mean, handle, butterfly valve, hard back and soft back?

- The butterfly valve of the handle butterfly valve is installed in the direction of the diameter of the pipe. In the butterfly valve body cylindrical channel, the disc shaped butterfly plate revolves around the axis, the rotation angle is between 0 degrees -90 degrees, when rotates to 90 degrees, the valve is fully open. This valve is mounted horizontally.Butterfly valve has an elastic seal and metal seal two types of seals. Resilient sealing valve. The sealing ring can be mounted on the valve body or attached to the periphery of the disc.The hard back is the metal seal, and the soft back is the elastic seal.

- Q: I got my timing belt done on a 1999 Civic Si on September 26 @ 113,699 miles. at 116,9xx miles I bent a valve on my third cylinder. How likely is it that the timing belt is the reason why this happened? I heard that if the timing belt is a tooth or so off, it could bend a valve. So is it likely that this could have happened? Anyway to check?

- If it was a timing belt issue it woudn't have only been one cylinder. And usually if it's only off by one tooth, it just runs poorly. IT has to be off by quite a bit, or the belt has to straight up break to bend a valve,, if that happened it would have made a horrible clanging noise repeatedly before it eventually sputtered out. the 1999 Si revs to what... 8000 rpms? You didn't happen to miss a shift and over-rev the engine, did you?

- Q: Butterfly valve model D344H and D343 difference

- [1] D344H-10C DN400, D343H-10C DN400, to talk about the 2 types of butterfly valves in common: D on behalf of 3 Representatives is butterfly valve, turbine driven, 4 representative is in the middle of flange, representing 10 kg pressure, C is the representative of the valve material is cast steel, DN400 represents the valve diameter; say that there the difference of the 2 models, there is a place where there are differences, second means 4 of the first models is the new type sealing valve structure is variable eccentric, second of the second models of the 3 represents the structure of the valve is three eccentric, and three eccentric seal type variable eccentric in fact, is a meaning.Sealed three eccentric butterfly valve, sealed variable eccentric butterfly valve, corresponding to the central butterfly valve and sealed single eccentric butterfly valve.

- Q: I have a 1993 Oldsmobile Cutlass Supreme and I think I have the case of the blow-by. The engine had high mileage, but was rebuilt b/c it stalled while driving. 3.1L V6 gasoline engine. The fuel filter and the fuel pump are brand new. Now we have the same problem a few months later. It stalls while driving. Its been sitting a while and won't start by itself, so I pulled off the air intake hose off of the air filter to spray starting fluid into it. I noticed oil puddled in the air intake hose, so I looked for the PCV valve on the rocker cover. There is a tube going from the air-intake hose to the rocker cover. I popped out the tube from the rocker cover and there is no PCV valve. Just tube. Is that where the PCV valve is supposed to go? If not, where can I find it on the engine? And could that possibly fix the blow-by and the stalling engine? I'd appreciate any help. Thanks in advance.

- top of the manifold

- Q: How to calculate the size of the manual butterfly valve?

- I don't know what size you mean, and what about DN in diameter, such as DN125, which means 125 cm in diameter

- Q: What are the butterfly valves models?

- Divided by way of drive(1) electric butterfly valve(2) pneumatic butterfly valve;(3) hydraulic butterfly valve;(4) manual butterfly valve;In the form of structure:(1) Central sealed butterfly valve(2) single eccentric sealed butterfly valve(3) double eccentric sealed butterfly valve(4) three eccentric sealed butterfly valve;

- Q: What is the working principle of the electric butterfly valve, and what's the difference between the butterfly valve and the butterfly valve?

- What's the difference between a worm valve and a manual butterfly valve?The turbine can light and close the valve here. It is more labor-saving and reliable. It is closed and open. Manual operation is relatively difficult, but the manual action is very fast. Fast switching.

- Q: Fire signal butterfly valve what role?

- Signal butterfly valve should be human action monitoring alarm, once closed, that is, to the system alarmYou ask the two time, I answer two times, you give two points

- Q: Butterfly valve in the use of the difference? Caliber?

- Role of butterfly valveButterfly valve is to use disc type to open and close parts reciprocating reciprocating about 90 degrees to open, close or adjust the flow of medium valve. The butterfly valve has the advantages of simple structure, small volume, light weight, material consumption, installation of small size, the driving performance of torque is small, simple operation, rapid, high chemical corrosion, and can also have good flow control function and closure characteristics, the use of butterfly valve is very extensive. Its varieties and quantities are still expanding, and the development of high temperature, high pressure, large caliber, high sealing, long life, excellent regulation, as well as multi-function development of one valve. Its reliability and other performance indicators have reached a high level. Disadvantages, there is a certain resistance to the medium.Gate valves are more used in steam pipes and large diameter water supply pipelines, because of the general requirements of fluid resistance is small, the use of gate valve.Valve is hand wheel rotation, stem upward movement. Flow is not the same, the gate valve requires full open. Need a higher installation space, the valve sealing surface has a certain self sealing capacity, its spool by the media pressure closely with the valve seat sealing surface contact, to achieve tight leakage. Wedge gate valve spool angle is generally 3~6 degrees, when forced to shut down excessive or temperature changes of the valve core is easy to die. Therefore, high temperature and high pressure wedge gate valve, in the structure have taken certain measures to prevent spool stuck. The valve in the opening and closing valve and valve seat sealing surface contact and mutual friction is always so easy to wear sealing surface, especially in close off the valve, the valve before and after the great pressure, sealing surface wear is more serious.

- Q: I did a compression check on my 350 chevy. I have low compression of 175psi on one cylinder.The other seven cylinders range from 195psi to 205psi Could the valves be too tight on the cylinder with 175 psi compression?

- unless they have been tampered with that wouldn't be it,they usually wont tighten up on their own,i would suspect maybe a valve with a slight burn place on it that's causing that to happen or a ring causing you to loose that much compression,try adding a small amount of oil in the cylinder and then do the compression test again,that will tell you if its a ring or a valve,that's a big loss of compression ,and when you see that much of drop its usually a burnt valve.good luck.

Send your message to us

Large Size Metal Seal Three Eccentric Industrial Butterfly ValveDN1600

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches