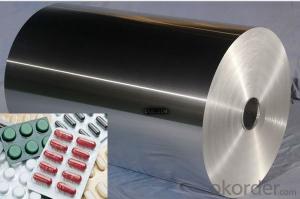

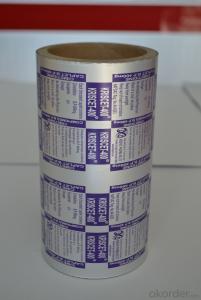

Tin Foil Aluminum Lacquered Pharmaceutical Foil for Pharmaceutical Packaging Application

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Lacquered Pharmaceutical Foil For Pharmaceutical Packaging Application

1. Light weight, clean, thin, good flexibility and cushioning;

2. Invariable if it is attacked repeatedly;

3. Low thermal conductivity and superior heat insulation;

4. Outstanding safety and environmentally friendly;

5. Easy to install, high efficiency;

6. Cost effective and versatile.

2.Why you want to choose us?

We've been specialized in aluminium foil for more than ten years, we know this product very well, we know what is good, what is the market price.

3.Specification and Application of Lacquered Pharmaceutical Foil For Pharmaceutical Packaging Application

Application: PTP foil, Cold forming foil, Alu-Alu foil

Alloy: 8011 / 8006 / 8079

Temper: H18 / O

Thickness & tolerance: 0.02 - 0.09 mm (+/- 6%)

Width & tolerance: 200 - 1650 mm (+/- 1mm)

Lacquer: HSL for PVC

Primer: Primer for painting

Standard: GB/T 3198 / ASTM - B209 / EN 546

4.Pictures:

5.FAQ:

1) What is your delivery time?

Our regular production time is over 30 days, It depends on the order quantity also.

2) What is your payment term?

We accept T/T, LC at sight, Usance LC 30, 60, 90, 120, 180 DAYS.

3) What is your price structure?

Our foil price is based on Shanghai Metal Price(SMM), not LME, but we could offer LME+ Conversion for your reference.

4) What is your Delivery term?

We do FOB, CFR, CIF, we don't do DDP.

5) Could you offer sample?

We could offer sample as your requirement. A4 Size sample is free for you, for bigger roll sample, it depends on the coil weight.

- Q: I have an old lacrosse stick shaft made of aliminumIts very light and it has quite a few dentsI want to flatten it into 'sword' shape because it seems really lightIs there a way I could go about doing this? I have basic tools, but can it be done? Thanks

- Fisher Price Dollhouse Furniture

- Q: Build a boat out of aluminum foil that can support/carry cargo. You may only use aluminum foil and glue. The boat cannot be more than 8 inches long, four inches wide, and four inches tall. The boat must float AT LEAST 500 grams.--------------------------------------------------------------------------------------PLEASE HELP !

- u layer sheets and glue em if u want for more strength. then u just keep folding up the sides in curves so that it looks like a boat. u will know when its enough. just keep perfecting it nd gluing it i guess. ive never made em with glue.

- Q: Every time I look I only find about a paragraoh of informationI need to know about his life like a biography not about his inventionThanks!

- i have always put a lil blanket on my birds cage, i have got two canarys and there fine with it, but just open the blanket a bit.

- Q: i am making the statue of liberty out of recylable objects any suggestions on the hands please help me this is very very very important!!!!!!!!!

- They do and they willI work and grew up in an upper class town, not super rich but Folsom is fairly wealthy consideringThere are citizens working at McDonald's, they're citizens doing the landscapng, doing the other jobs that required for a functioning societySure there are those people who thought that a job was beneath them but the funny thing is, now they're unemployed.

- Q: A package of aluminum foil contains 50.0 ft, which weighs 8.0 ouncesWhat is the thickness of the foil in millimeters??

- Kashi snacks are full of fiber and are always filling (:

- Q: The mac books are made from aluminum

- A) Laser Etching (Look round the internet for a site that does it) B) Just use stickers (Better for resale ect.)

- Q: If I were to draw an electron notation for an aluminum (Al) atom, what is the highest energy level I would reach? I really need help on this oneoh and explanation would greatly help

- I checked at a Hoover Dam (not damn) site that said a tower crane fell over on Friday, closing the road in both directionsThe road is now re-opened, as of Monday night 8pm.

- Q: Or some other similar late summer kid snack like this.

- it relies upon on the hub for the internetin case you dont have the nicely suited hub, it wont allow you to do ityou may desire to pass to superb purchase or someplace and ask them in the event that they have any community hubs.

- Q: and i dont know whhat im doing!its a 9.90 lbit says fully cooked smokeed hamm!so what degree do i put it and for how long?helpp mee!

- You have to read through the estate agent language we who live here do get used to itSpacious usually means smallLarge is large compared to what else is available in the area that it is inI think what you are going to need to do is to view some of the properties in the area that you are interested in so that you can do a comparison and get an idea of what you can get for your budget I agree with youHaving bought property in France I find that having the size of the property means that you can easily see ones that you consider too small or too big without the need to viewHere in the UK it is not traditional to put the size.

Send your message to us

Tin Foil Aluminum Lacquered Pharmaceutical Foil for Pharmaceutical Packaging Application

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords