Kitchen Hardware Panhandle

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Piece/Pieces pc

- Supply Capability:

- 60 Ton/Tons Per Month Negotiable pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Casting Stainless Steel Cookware Accessory --Panhandle

Materials:304, 316, 316L

Surface Treatment:Stain & Mirror Polish

- Q: Curtain wall design documents review how qualified newspaper supervision

- You should say is the curtain wall of the drawings review certificate. Do not need any format, do not have a separate inspection, copy a copy of the supervision to the OK. The The And the original should be given to the Party

- Q: Department of Construction and Construction (2017) 38 on the construction of glass curtain wall what are the requirements

- Glass curtain wall should adopt laminated glass, homogeneous tempered glass or ultra-white glass. The use of tempered glass should meet the existing national standard "building doors and windows curtain wall with tempered glass" JG / T455 requirements.

- Q: What is the construction process of the point glass curtain wall?

- The curtain wall is the outer wall of the building, is not bearing the weight, just like the curtain hanging. At present, many large and high-rise buildings commonly used in light walls are used this.

- Q: Stainless steel sheet approach to provide any proof of quality documents

- The simplest is the material certificate slightly, generally large steel mills are made of stainless steel material certificate. If your product needs environmentally friendly, then the use of stainless steel on the need for environmental certification, like ROSH certification.

- Q: What is the classification of building materials?

- Generally have: progress, quality, safety, cost

- Q: Curtain wall energy-saving project acceptance of the general project which

- Curtain wall thermal construction requirements, including insulation material installation, steam layer, curtain wall and wall joints, structural joints, structural joints, hot bridge parts, heat sink joints, unit curtain wall plate joints, condensate set Row structure and so on.

- Q: How many calculations for a square meter of material?

- Upstairs is also quite detailed, when we offer the general is for different types of curtain wall (different panels, keel in different forms to be separated), take a standard position of the surface, calculate the amount of various materials inside * Loss coefficient, and then divided by the area of this face, came out no square meters of the material.

- Q: Bidding documents are glass curtain wall, the party has to check the aluminum alloy window, how to do?

- Should be agreed by the contract, if the contract is not agreed, that is, according to the actual settlement of the two sides resolved.

- Q: What are the curtain wall materials to do? The beginning of the time

- Other quality assurance information.

- Q: Fire aluminum glass is what glass where to sell

- This involves more, you can special check, of course, you need to be specific communication

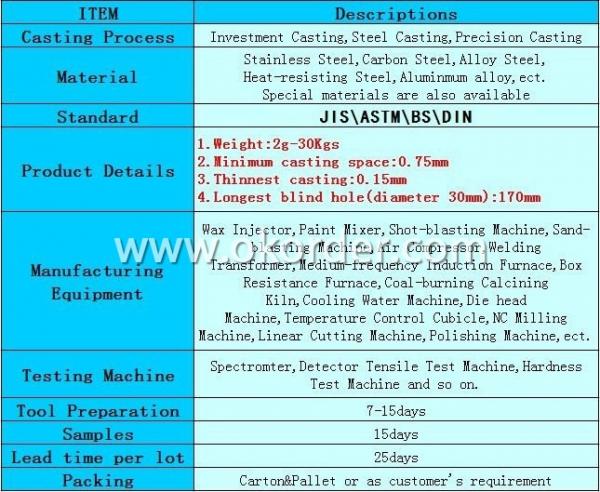

We make every step strictly, especially for testing. We have spectroscopy analysis, metallographic microscope, tensile, hardness, impact and X-Ray test, liquid penetrant, magnetic particle test and NTD inspection. The interpretation of the data from these test facilities could promise the best quality of our raw casting, any required test report of process should be attached before delivery of all the casting parts of each.

1. Manufacturer Overview

| Location | Guangdong,China (Mainland) |

| Year Established | 2008 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Oceania Mid East Eastern Asia Western Europe |

| Company Certifications | ISO 9001:2000;ISO 9001:2008;QS-System nach EN 764-5, Abschnitt 4.2, und AD 2000-Merkblatt W O |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Kitchen Hardware Panhandle

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Piece/Pieces pc

- Supply Capability:

- 60 Ton/Tons Per Month Negotiable pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords