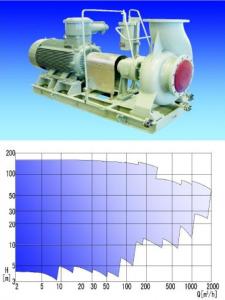

KCZ series standard chemical process pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product overview

KCZ standard chemical process pump is based on the absorption of similar products at home and abroad advanced technology, development and design in accordance with the international standard of international standard chemical process pump. KCZ standard chemical process pump structure was optimized by using CAD modular design, novel structure, reliable and good parts interchangeability, advanced hydraulic model, high efficiency, good cavitation, can satisfy the requirements of performance parameters under various working conditions.

Application field

Can be widely used in chemical, petroleum, metallurgy, power station, food, sugar, pharmaceutical, paper, synthetic fiber, water supply, seawater desalination, environmental protection engineering, heating and air conditioning and other fields.

Product features

1, KCZ standard chemical process pump technical conditions in accordance with ISO standards, safety and reliability of the operation of the pump, versatility, applicability is wide and enforcement of the structure of industrial process pump at the same time, after the pull type design, safe and convenient pump disassembling maintenance;

2, adopt CAD modular structure design, component assembly, with series products between parts with maximum interchangeability;

3, adopts the integral casting closed impeller, strong adaptability to the operating conditions, with high efficiency and cavitation performance of the optimal, with a standard back impeller impeller or balance hole, can reduce the axial thrust and seal chamber pressure, prolong the service life of sealing and bearing.

4, the center line of the pump body at the top of the export and pump foot support, has the largest pipe load resistance, large flow high lift pump double volute design of the runner, radial force is small, dynamic deflection is small, the pump running smoothly, pump casing corrosion quantity is big, and have a replaceable wear ring, maximize the corrosion resistance of the pump and prolong the service life of pump;

5, pump shaft rigidity design, choose heavy cylindrical roller and double angular contact ball bearing in pairs, can bear radial load and axial load, the pump shaft overall strengthen rigidity, impeller dynamic balance test and calibration at the same time, the pump running, low noise, small vibration of shaft seal and bearing life is very good;

6, dry structure design, impeller and nuts and sleeves on the shaft, impeller nut and impeller, are seal between the impeller and shaft sleeve, under the condition of normal use, pump shaft do not contact with the medium, is not subject to corrosion medium, further improve the safety and reliability of the pump operation;

- Q: Why should the pump be closed when the centrifugal pump is started?

- Centrifugal pump has an important characteristic: when the pressure (head) is very low, the flow will be great, which can be seen from the characteristics of the pump curve. While the pump power is directly proportional to the flow rate, pump start, no pressure in the pipeline, caused by the pump flow, high power pump, and the pump motor, the rotating part from rest to high-speed operation, need a lot of acceleration, it will cause a great starting current

- Q: What are the functions of a disposable infusion pump?

- This is a very professional question, ha!I only know disposable infusion pumpsAttached: intelligent medical infusion pump and its application

- Q: I would like to ask, constant pressure pump set pressure 20Mpa, the actual load is 15Mpa, then the constant pressure pump outlet pressure? If it is 20Mpa, then where is the loss of 5Mpa? If 15Mpa, the constant pressure pump 20Mpa how to understand? In addition, the constant pressure pump pressure is defined when the flow began to reduce the point, or a sharp drop in flow after the point?

- 15MPa. 20MPa means that if you enter the 20MPa, the variable mechanism will work, and the flow at this time automatically matches the load. 20MPa used to supply the fuel by maximum displacement.

- Q: Why should I pump the pump before starting the centrifugal pump?

- 1., if it is backward flow, it is not pumping;2., if the pump is installed underwater (such as submersible sewage pump), it is not pumping;3. pump is for installation in the form of suction. If no diversion irrigation pump, then the pump is full of air quality, air density is less than water, the pump will not be inside the gas out, the pump pressure will not be far less than the atmospheric pressure, the water will not be pressed into the pump to pump through irrigation formed inside the closed environment, the pump will start water out will cause local vacuum, entrance external water pressure into the pump is in inside and outside differential pressure, complete water movement. (vacuum water diversion is directly through the vacuum pump pumping the air in the pump, resulting in internal and external pressure difference, the external water pressure in the internal and external pressure is press into the inlet of the pump. The principle is the same as the pump. A standard atmosphere of =10m water column.)

- Q: What's the difference between non negative pressure and variable frequency water pump?

- No negative pressure is superposed pressure intelligent frequency conversion equipment, pump frequency operation is no negative pressure difference, and the variable frequency pump, variable frequency pump is advanced municipal tap water tank or pool, pump from the tank or pond water pressure to set pressure to the pressure water supply, and no negative pressure directly from water the municipal pipeline, using the original municipal 2~3 kilograms of pressure

- Q: The main factors affecting the performance of centrifugal pumps

- The specific speed is deduced by the law of hydraulic similarity, and the similarity between the hydraulic characteristics of centrifugal pumps is similar. In centrifugal pumps, the specific speed is often interpreted as: the pump works at the highest efficiency, generating a lift of LM, a flow rate of 0.075m, and the power consumed by the /s at 0. 735kW

- Q: Shielding pump is the main drawback of electricity? How much does it cost more than an ordinary centrifugal pump? Is there any noise in the running of the canned pump? How much is it lower than the noise of the common centrifugal pump?

- The ordinary centrifugal pump is driven by coupling the pump impeller shaft is connected with the motor shaft, the impeller and the motor rotates while working and shielding pump is a kind of non seal pumps, pump and motor is sealed in a medium filled by pumping the pressure vessel, the pressure vessel only static seal and, by a group of wires to provide a rotating magnetic field and rotor drive. The structure eliminates the rotary shaft sealing device of the traditional centrifugal pump, so the utility model can be completely free from leakage.

- Q: What is the function of the heating pump system for the water pump design?

- As the feed water temperature is higher, in the case of non warm pump start, will make the pump body is subject to greater thermal impact; in addition, the flow components with the pump contact heating fast, not contact with water directly heating slowly. This expansion due to uneven speed, it will inevitably produce thermal stress, deformation of the pump body, sealing surface, the joint surface is lax and leaking phenomenon. Therefore, the warm water pump system is designed for the water pump.

- Q: Direct connection pump What is straight pump and non direct pump? What's the difference in structure?

- The direct connected pump impeller is directly mounted on the motor shaft, and the non direct connected pump and motor are two shafts, and the two shafts transmit torque through the coupling

- Q: What is the distance between the pump and the wall?

- Mainly depends on the maintenance, installation is convenient, but there is no other requirements.

Send your message to us

KCZ series standard chemical process pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords