J55|N80 Slotted Liner

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Descriptions :J55|N80 Slotted Liner

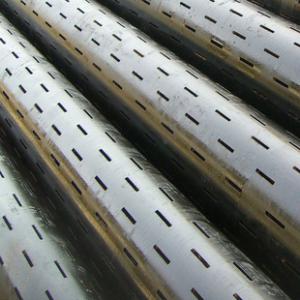

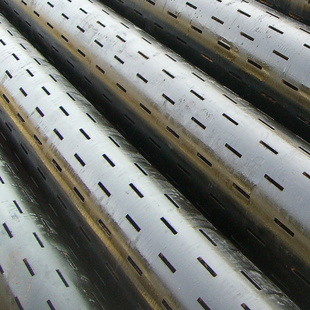

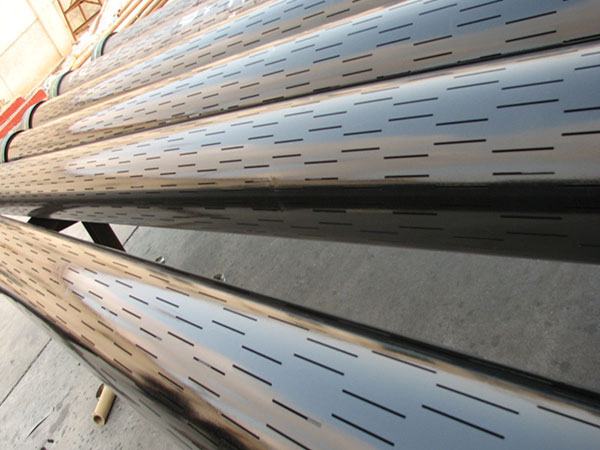

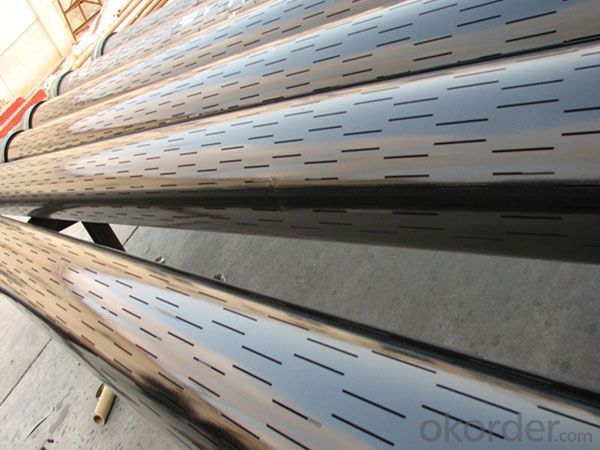

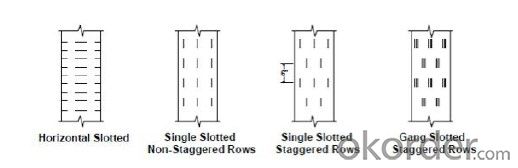

Slotted liners are used in gravel packed completions to prevent the production of gravel pack sand or can be used in stand-alone service when the formation grain size is large. Slot widths are often referred to in terms of "gage" or "gauge". Slot or screen gage is simply the width of the opening in inches multiplied by a 1,000. For instance, a 12 gage screen has openings of 0.012 inches. Slotted liners are manufactured by machining slot openings through oil-field tubulars with small rotary saws. Slotted liners are fabricated in a variety of patterns as illustrated in Figure.

The minimum slot widths that can be achieved is about 0.012 inches; however, slots widths cut below 0.030 inches in thickness involve higher costs because of excessive machine down time to replace broken saw blades that become overheated, warped and break. While the slotted liners are usually less costly than wire-wrapped screens, they have a smaller inflow area and experience higher pressure drops during production.

Slotted liners also plug more readily than screens and are used where well productivity is low and economics cannot support the use of screens. The single slot staggered pattern is generally preferred because a greater portion of the original strength of the pipe is preserved. The staggered pattern also gives a more uniform distribution of slots over the surface area of the pipe. The single slot staggered pattern is slotted with an even number of rows around the pipe with a typical 6 inch longitudinal spacing of slot rows.

SLOTTED LINER GEOMETRIES

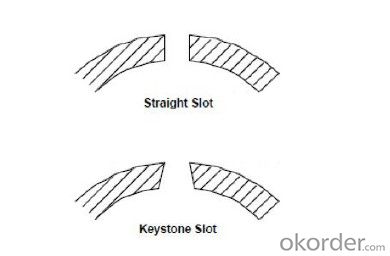

The slots can be straight or keystone shaped as illustrated in Figure. The keystone slot is narrower on the outside surface of the pipe than on the inside. Slots formed in this way have an inverted "V" cross-sectional area and are less prone to plugging since any particle passing through the slot at the OD of the pipe will continue to flow through rather than lodging within the slot.

STRAIGHT AND KEYSTONE SHAPED SLOTS

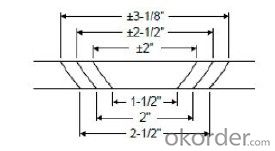

The length of the individual slots is gauged on the ID of the pipe. Usual practice dictates 1½ inch long slots for slot widths 0.030" and under, 2 inch long slots for slot widths between 0.030 to 0.060 inches and 2½ inch long slots for slot widths 0.060 inches and larger (see Figure 6.4). Slot width tolerance is generally 0.003 inches for widths 0.040 inches and wider and 0.002 inches for widths less than 0.040 inches.

STANDARD SLOT LENGTHS

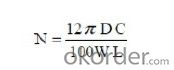

Slotted liners are generally designed to have a 3 percent open area relative to the OD surface area of the pipe although open areas up to 6 percent are feasible in some cases. The number of slots per foot required to achieve a given open area is calculated with the equation below.

where: N = required slots/foot (if N < 32, round up to the nearest multiple of four, if N > 32, round up to the nearest multiple of 8) Pie = constant (3.1416) D = outer diameter of pipe (inches) C = required open area (percent) W = slot width (inches) L = length of slot measured on ID of pipe (inches)

Dalipal Company is one of the most famous enterprises of china professionally producing pipeline and oil casing.We can supply API 5CT series of pipeline and oil casing with all kinds of specifications and materials.We have first-class production equipment and technology.

- Q: How are steel pipes used in the construction of stormwater drainage systems?

- Steel pipes are commonly used in the construction of stormwater drainage systems due to their durability and strength. They serve as underground conduits to efficiently transport stormwater away from built-up areas, preventing flooding and water damage. Steel pipes offer high resistance to external pressure and are capable of withstanding heavy loads, making them suitable for underground installations. Additionally, their corrosion-resistant properties ensure long-term effectiveness and minimize maintenance requirements. Overall, steel pipes are essential components in stormwater drainage systems, providing reliable and efficient water management solutions.

- Q: How do you calculate the buoyancy of submerged steel pipes?

- In order to calculate the buoyancy of submerged steel pipes, one must take into account Archimedes' buoyancy principle. According to this principle, the force exerted on an object submerged in a fluid is equal to the weight of the fluid displaced by the object. To calculate the buoyant force, it is necessary to determine the volume of fluid displaced by the submerged steel pipe. This can be done by multiplying the cross-sectional area of the pipe by the length of the submerged portion. Next, it is important to ascertain the density of the fluid in which the steel pipe is submerged. This information can be obtained from the properties of the fluid or by referring to known values. Once the volume and density of the fluid have been determined, the weight of the fluid displaced by the submerged pipe can be calculated using the equation: weight = volume × density × acceleration due to gravity. Finally, the buoyant force can be calculated by multiplying the weight of the displaced fluid by the acceleration due to gravity. This will yield the upward force exerted on the submerged steel pipe by the fluid. When accurately calculating the buoyancy of submerged steel pipes, it is crucial to take into account additional factors, such as the weight of the pipe itself, any attached equipment or coatings, and the specific conditions of the fluid in which it is submerged.

- Q: What are the different methods of pipe joining for steel pipes?

- There are several different methods of pipe joining for steel pipes. Some of the most common methods include: 1. Butt Welding: This method involves welding the ends of two steel pipes together. The ends are prepared by beveling or facing them to create a V-groove, which is then filled with molten metal to create a strong and durable joint. 2. Socket Welding: In this method, a socket is welded onto the end of a steel pipe, and then another pipe is inserted into the socket and welded in place. This creates a strong joint that is resistant to leakage and corrosion. 3. Threaded Joint: Steel pipes can also be joined using threaded connections. The ends of the pipes are threaded, and then a threaded coupling or union is used to connect them. This method is commonly used for smaller diameter pipes and allows for easy disassembly and reassembly. 4. Flanged Joint: Flanged joints are used for larger diameter pipes and involve attaching a flange to the end of each pipe. The flanges are then bolted together using gaskets to create a tight and secure joint. This method is commonly used in industries such as oil and gas, water treatment, and chemical processing. 5. Grooved Joint: Grooved joints involve using a grooving machine to create a groove around the outside of the pipe. A coupling or fitting is then inserted into the groove and secured with bolts or clamps. This method is quick and easy to install and allows for easy disassembly and reassembly. Each method of pipe joining has its own advantages and disadvantages, and the choice of method will depend on factors such as the size of the pipes, the application, and the required level of strength and durability.

- Q: What are the common standards for coating and lining of steel pipes?

- Various organizations and regulatory bodies have outlined the common standards for coating and lining steel pipes to ensure their durability, corrosion resistance, and overall quality. These standards are widely recognized and utilized in different industries. Here are some examples: 1. The American Society for Testing and Materials (ASTM) has developed numerous standards for coating and lining steel pipes. For instance, ASTM A775/A775M addresses epoxy-coated reinforcing steel, ASTM A1064/A1064M focuses on metallic-coated steel wire, and ASTM A1057/A1057M covers fusion-bonded epoxy-coated steel reinforcement. 2. The American Water Works Association (AWWA) has established standards specifically for coating and lining steel pipes used in the water industry. AWWA C210 deals with liquid epoxy coating systems for both the interior and exterior of steel water pipelines, while AWWA C213 focuses on fusion-bonded epoxy coating for these pipelines. 3. The National Association of Corrosion Engineers (NACE) develops standards and recommended practices for corrosion control in steel pipes. NACE SP0169 provides guidelines for selecting and applying coatings for underground or submerged steel pipelines, and NACE SP0198 offers recommendations for external coatings of steel pipelines. 4. The International Organization for Standardization (ISO) has also developed various standards pertaining to coating and lining steel pipes. ISO 21809-1 specifies the requirements for external coatings applied to buried or submerged pipelines, while ISO 21809-2 concentrates on the internal coating and lining of such pipelines. These standards encompass multiple aspects of the coating and lining process, including surface preparation, application methods, minimum coating thickness, adhesion, and quality control. Adhering to these standards ensures that steel pipes receive proper protection against corrosion, abrasion, and other forms of deterioration. Consequently, they enjoy a longer service life and enhanced performance in industries such as oil and gas, water supply, and infrastructure.

- Q: What is the difference between steel pipes and FRP pipes?

- Steel pipes and FRP (Fiberglass Reinforced Plastic) pipes differ in their material composition, properties, and applications. While steel pipes are made from steel, FRP pipes are composed of a combination of resin and fiberglass. Steel pipes are known for their high strength and durability, making them suitable for heavy-duty applications such as transporting oil, gas, and water. On the other hand, FRP pipes are lightweight, corrosion-resistant, and have excellent chemical resistance, making them ideal for applications where corrosion is a concern, such as in the chemical industry or in sewage systems. Furthermore, FRP pipes offer better insulation properties and are easier to install due to their lighter weight. Overall, the choice between steel pipes and FRP pipes depends on the specific requirements and conditions of the application.

- Q: What are the different types of steel pipe fittings for gas pipelines?

- There are several types of steel pipe fittings commonly used for gas pipelines, including elbows, tees, reducers, couplings, flanges, and valves. These fittings are essential for connecting and controlling the flow of gas within the pipeline system.

- Q: Can steel pipes be used for compressed air systems?

- Yes, steel pipes can be used for compressed air systems. Steel pipes are commonly used for their strength and durability, making them suitable for handling the high pressures involved in compressed air systems. However, it is important to ensure that the steel pipes are specifically designed and rated for compressed air applications to ensure safety and prevent any potential leaks or failures.

- Q: What are the environmental impacts of steel pipe production and disposal?

- The production and disposal of steel pipes have significant environmental impacts. Firstly, the production of steel pipes requires the extraction of raw materials such as iron ore, coal, and limestone. This extraction process leads to habitat destruction, deforestation, and soil erosion. Additionally, mining and processing these materials require a considerable amount of energy, often derived from fossil fuels, contributing to greenhouse gas emissions and air pollution. The manufacturing process itself involves various stages, including melting, casting, rolling, and coating, all of which require substantial energy inputs and emit significant amounts of carbon dioxide and other greenhouse gases. Moreover, the production of steel pipes involves the use of chemicals and additives that can be harmful to the environment if not managed properly. Furthermore, during the disposal of steel pipes, if not recycled or properly managed, they can end up in landfills, contributing to waste accumulation and taking up valuable space. Steel is generally non-biodegradable and can take hundreds of years to decompose. When steel pipes are dumped in landfills, they can release toxic substances and heavy metals, which can contaminate soil and groundwater. However, it is important to note that steel pipes are highly recyclable, and recycling them significantly reduces the environmental impact. Recycling steel pipes helps conserve natural resources, reduces energy consumption, and lowers greenhouse gas emissions. Additionally, using recycled steel in the production of new pipes requires less energy and results in fewer emissions compared to using virgin materials. To minimize the environmental impacts of steel pipe production and disposal, it is crucial to promote sustainable practices throughout the entire lifecycle of the product. This includes reducing energy consumption, utilizing renewable energy sources, implementing proper waste management strategies, and encouraging the recycling and reuse of steel pipes.

- Q: Can steel pipes be used for paper mills?

- Yes, steel pipes can be used for paper mills. Steel pipes are often used in paper mills for various applications such as transporting water, steam, chemicals, and pulp. They are preferred for their durability, resistance to corrosion, and ability to handle high pressure and temperature conditions commonly found in paper mill operations.

- Q: Are steel pipes suitable for potable water systems?

- Indeed, steel pipes prove to be an appropriate choice for potable water systems. Due to their robustness, longevity, and ability to resist corrosion, they are frequently employed in such systems. These pipes can endure substantial pressure and transport significant quantities of water. Furthermore, their versatility is evident as they can be effortlessly welded together, rendering them suitable for a wide range of applications within potable water systems. Nevertheless, it is crucial to emphasize the importance of regular inspections and adequate maintenance to avert potential problems such as rust or contamination.

Send your message to us

J55|N80 Slotted Liner

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords