Interior decorative board CSB Fire and moisture-proof, high flatness Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

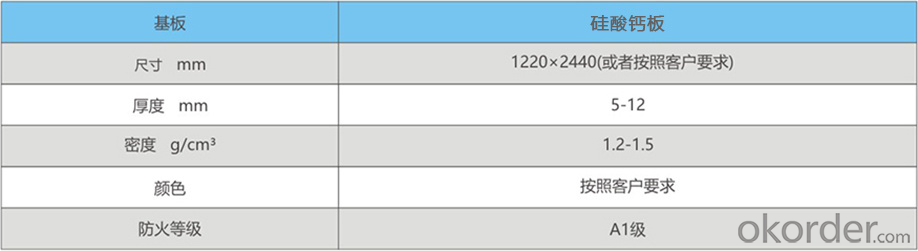

Specification

Interior decorative board

Interior decorative board, It is a green, low carbon, energy saving, environmentally friendly new decorative panel material, selected no asbestos, zero radiation of high density calcium silicate plate as the substrate; surface color paper and back balance paper soaked with special formula resin

Product features

Fire and moisture-proof, high flatness, strong decorative nature, rich wood grain texture, green environmental protection, do not contain asbestos and other harmful substances.

Product application

Products instead of ceramic tile, marble, etc., can be applicable to urban airport, subway, municipal construction in various fields, has been widely used in hospitals, residential, office, hotel, entertainment places of interior decoration

- Q: Calcium silicate board can be used in the roof

- Silica calcium board is composed of siliceous and calcareous materials, by the pulp, molding, steam curing, drying, sanding and post processing and other processes made of a new type of sheet. Products with light high strength, fire insulation, processing and other advantages, can be widely used in high-rise and public buildings of the fire wall panels, ceiling panels, ducts, a variety of ships compartment board, and fire doors.

- Q: Decorated with calcium silicate board to do the ceiling after the discovery of which contains asbestos ingredients. With the putty powder and paint brush brush is it harmful to the body only two of the impact of it?

- I am a manufacturer of calcium silicate board, in our domestic most of the internal and external decoration of the use of calcium silicate board are containing asbestos, Shanghai Expo Park are used in many of these, although you are assured, harmless.

- Q: With calcium silicate board across the wall, noise fiber also added, why the sound is not ideal, I would like to ask on the basis of the original method to improve the sound insulation effect?

- Plus sponge and foam out of the board, to look at the scraping wallpaper, so that the sound is the practice of the general studio, if asked for higher quality, ask me

- Q: What kind of ceiling does the open kitchen do? Is it the same as the lobby to do the calcium silicate board, or do it?

- The kitchen is usually fitted with an aluminum gusset plate or an integrated ceiling

- Q: Toilet with silicon calcium board ceiling, with the general opening device can not open

- Do not know how big you want to open, small can use alloy hole device

- Q: Silicon calcium board is not the fire board silicon calcium board is not the fire board

- As a new green building materials, in addition to the function of the traditional gypsum board, but also has excellent fire performance and moisture resistance, the advantages of long life, a large number of industrial and commercial buildings used in ceiling ceilings and partitions, home decoration, furniture liner , Billboards, panels, warehouses, warehouses, floorboards, and tunnels.

- Q: Buy the house is fine decoration, wood flooring poor quality to tile bathroom ceiling is calcium silicate board, it is necessary to replace it? Need to change the material of the ceiling?

- Bathroom environment is more complex, humidity, bacteria, air quality is poor, if it is calcium silicate board, it is easy to be affected, resulting in security risks such as rupture, beautiful drawbacks, that is, mold attached to the above.

- Q: Living room light steel keel ceiling is gypsum board seal or calcium silicate board seal is better?

- If you are a large area of the ceiling, or use strong, no need for a small area

- Q: Calcium silicate sound - absorbing panels with what inspection lot

- Silicon calcium board is a compact board, basically airtight. Relative to the sound-absorbing panels heavier and harder. Is a sealed plate. Mainly from the sound effects. That is to stop the sound on both sides of the space in the spread of space.

- Q: What is the difference between calcium silicate board and mineral wool board?

- Mineral wool board from the slag through high temperature, high pressure, high-speed rotation, remove impurities, washed into mineral wool, mineral wool board mainly by mineral wool, adhesives, pulp, perlite composition. The mineral wool board has similar characteristics of silicon calcium board, but the sound insulation performance is worse than that of gypsum board and silicon calcium board. It can not be waterproof. It is easy to deform.

Send your message to us

Interior decorative board CSB Fire and moisture-proof, high flatness Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches