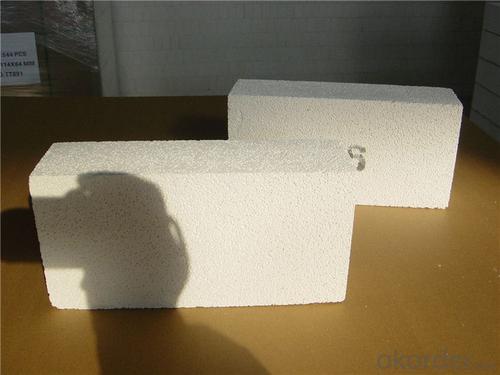

Insulating Fire Brick with Excellent Insulating Effect - Common Size for Heat Treatment Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNBM conforms strictly to the requirements of ISO 9000 quality control system during the production. MSDS is also available if you want. The thermal insulation fire clay brick meet with the requirements of ASTM & JIS standards. So please stay cool with our quality.

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Insulating Fire Brick Technical index

Brand Quality | JM23 | JM26 | JM28 | JM30 | JM32 | |

Bulk Density (g/cm3) | 0.52 | 0.78 | 0.88 | 1.03 | 1.25 | |

1.2 | 1.6 | 2.1 | 2.5 | 3.5 | ||

Modulus of Rupture (Mpa) | 0.9 | 1.4 | 1.6 | 2.1 | 2.1 | |

-0.5 | 1400℃ -0.4 | 1510℃ -0.5 | 1620℃ -0.9 | 1730℃ -0.9 | ||

Thermal Expansion 1100℃(%) |

0.5 |

0.7 |

0.8 |

0.9 |

1.1 | |

Thermal conductivity(W/m.k)

| 400℃ | 0.14 | 0.27 | 0.32 | 0.41 | 0.49 |

600℃ | 0.16 | 0.29 | 0.34 | 0.43 | 0.50 | |

800℃ | 0.18 | 0.31 | 0.36 | 0.44 | 0.51 | |

1000℃ | 0.20 | 0.33 | 0.38 | 0.45 | 0.53 | |

Al2O3 | 37 | 58 | 67 | 73 | 77 | |

Fe2O3 | 0.7 | 0.7 | 0.6 | 0.5 | 0.4 | |

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

3 large flexible crushing and sieving lines for grit production lines

2 units of 2000KVA furnaces for Boron Carbide fusion

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

(6)Free sample

FAQs

Q1 |

What’s the transport method? |

A1 | FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo. |

Q2 |

What’s the required payment term? |

A2 | Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation. |

Q3 |

Which country are our products exported to? |

A3 | Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations. |

- Q: Can insulating fire bricks be used in the construction of smelters or foundries?

- Yes, insulating fire bricks can be used in the construction of smelters or foundries. Insulating fire bricks have excellent thermal insulation properties and can withstand high temperatures, making them suitable for lining the walls and floors of smelters or foundries. They help to retain heat, improve energy efficiency, and protect the surrounding structures from extreme temperatures.

- Q: Can insulating fire bricks be used in kiln car construction?

- Yes, insulating fire bricks can be used in kiln car construction. These bricks possess excellent thermal insulation properties, making them suitable for creating an energy-efficient and temperature-stable environment inside the kiln. Additionally, their lightweight nature simplifies the construction process and allows for easy handling of kiln cars.

- Q: How do insulating fire bricks affect the overall thermal stability of a structure?

- Insulating fire bricks enhance the overall thermal stability of a structure as they have low thermal conductivity, preventing heat transfer and minimizing energy loss. By acting as a barrier, these bricks help in maintaining a consistent temperature within the structure, reducing the impact of external temperature fluctuations. This enhanced thermal stability promotes energy efficiency, cost savings, and a more comfortable environment within the structure.

- Q: Can insulating fire bricks be used in the construction of combustion chambers for rocket engines?

- Insulating fire bricks are capable of being utilized in the construction of rocket engine combustion chambers. They are specifically engineered to endure elevated temperatures and provide exceptional thermal insulation. This makes them an ideal option for situations involving extreme heat, such as rocket engine combustion chambers. The main purpose of insulating fire bricks in a rocket engine's combustion chamber is to shield the surrounding structure from the intense heat generated during combustion. By offering insulation, these bricks aid in minimizing the transfer of heat to the outer walls of the combustion chamber, thus averting damage and ensuring the chamber's structural integrity. Moreover, insulating fire bricks possess a lightweight composition and exhibit low thermal conductivity, enabling them to effectively retain heat within the combustion chamber. This characteristic is vital for maintaining optimal combustion efficiency and enhancing rocket performance. In addition to their thermal properties, insulating fire bricks are recognized for their durability and resistance to thermal shock. This attribute is particularly valuable in rocket engine applications where rapid temperature fluctuations can occur, such as during ignition or shutdown sequences. The ability of insulating fire bricks to endure such thermal stresses is imperative for the dependable operation and extended lifespan of the combustion chamber. Overall, insulating fire bricks are a suitable choice for constructing combustion chambers in rocket engines due to their ability to withstand high temperatures, provide thermal insulation, possess a lightweight nature, and exhibit durability.

- Q: Can insulating fire bricks be used in the construction of steel rolling mills?

- Yes, insulating fire bricks can be used in the construction of steel rolling mills. Insulating fire bricks are designed to have excellent thermal insulation properties, which makes them ideal for applications that require high temperatures and heat containment. In steel rolling mills, where high temperatures are involved, insulating fire bricks can be used to line the walls of furnaces, ovens, and other heat-processing equipment. These bricks help to reduce heat loss, increase energy efficiency, and maintain a stable temperature environment, which is crucial in the steel rolling process. Additionally, insulating fire bricks are lightweight and easy to install, making them a practical choice for construction in steel rolling mills.

- Q: Can insulating fire bricks be used in the construction of lime kilns?

- Yes, insulating fire bricks can be used in the construction of lime kilns. These bricks are specially designed to withstand high temperatures and provide excellent insulation, making them suitable for lining the interior of lime kilns. Their ability to retain heat and reduce heat loss can help enhance the efficiency and performance of the lime kiln.

- Q: Can insulating fire bricks be used in the construction of smelter crucibles?

- Yes, insulating fire bricks can be used in the construction of smelter crucibles. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for use in smelting applications. They help to retain heat and minimize heat loss, ensuring efficient and effective smelting processes.

- Q: Are insulating fire bricks suitable for insulation in gas turbines?

- Insulating fire bricks, although great for high-temperature insulation in furnaces and kilns, are typically unsuitable for insulating gas turbines. Gas turbines operate at even higher temperatures and thus require specialized insulation materials. These materials, such as thermal barrier coatings, ceramic fiber blankets, or other advanced insulation materials, are specifically designed to withstand the extreme heat and pressure conditions within the turbine. They not only provide excellent thermal insulation but also possess properties like erosion resistance, low thermal conductivity, and high mechanical strength. Therefore, while insulating fire bricks have their merits in specific applications, they are not the ideal choice for gas turbine insulation.

- Q: Can insulating fire bricks be used in sewage treatment plants?

- Indeed, insulating fire bricks can find their application in sewage treatment plants. These bricks are specifically engineered to possess exceptional thermal insulation properties, rendering them suitable for high-temperature scenarios. Within sewage treatment plants, various processes necessitate the utilization of heat, such as anaerobic digestion or sludge incineration. Consequently, insulating fire bricks can be employed to encase the walls, floors, and roofs of incinerators or digesters, thereby facilitating the retention of generated heat and enhancing energy efficiency. Moreover, sewage treatment plants often confront corrosive and abrasive surroundings as a result of the presence of chemicals, acids, and solids within the wastewater. Notably, insulating fire bricks are forged from top-notch refractory materials, boasting resistance against chemical assault and erosion. This characteristic endows them with suitability for lining tanks, pipes, or other equipment that may come into contact with corrosive substances. Furthermore, owing to their lightweight nature, insulating fire bricks prove to be more manageable and straightforward to install in comparison to alternative types of refractory materials. This aspect can be particularly advantageous in sewage treatment plants where the need for frequent maintenance or repairs may arise. All in all, insulating fire bricks stand as a versatile and long-lasting choice for implementation within sewage treatment plants. They offer exceptional thermal insulation, resilience against corrosive environments, and ease of installation.

- Q: Can insulating fire bricks be cut or shaped to fit different spaces?

- Yes, insulating fire bricks can be cut or shaped to fit different spaces. Insulating fire bricks are made from lightweight materials that can be easily cut or shaped using common tools such as saws, knives, or rasps. This allows for customization and precise fitting in various spaces, including fireplaces, kilns, furnaces, and other high-temperature applications. It is important to remember, however, that proper safety precautions should be taken when cutting or shaping insulating fire bricks, as they may produce dust or debris.

Send your message to us

Insulating Fire Brick with Excellent Insulating Effect - Common Size for Heat Treatment Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords