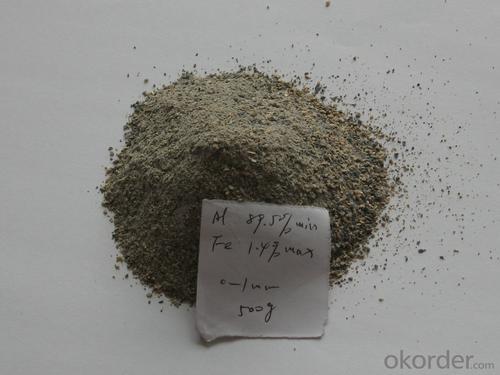

Raw Materials for Refractory Insulating Castable Polyurethane Cement Refractory Cement

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

High strength wear resistant castable is mixed by corundum,high-quality bauxite clinker,silicon carbide as aggregate,all kinds of powder,ultra-fine powder,micropowder,alumina powder and additives as admixture with strict mixture ratios according to different varieties.its main characters are:high strength in normal and medium temperature,wear resistance and erosion resistance,thermal shock stability,etc.it is mainly used in the position of coal-fired circulating fluidized bed boilers,waster incineration furnace,lining of fluid-bed furnace etc,where are seriously abraded.

Competitive Advantage:

1.Best price, make the products competitive in your market

2.Abundant Experience.

3.Strict Quality Control. Meet clients'quality requirement.

4.Large stocks. Guarantee prompt delivery.

5.Safty packing,prompt delivery time,and excellent after-sales services.

6.Professional Packing. Avoid damage and secure the goods in transportation

Technical data:

Item | Index | Brand | |||

HSC-80 | HSC-75 | HSC-65 | HSC-60 | ||

Chemical composition% | Al2O3 | ≥80 | ≥75 | ≥65 | ≥60 |

SiO2 | ≤15 | ≤19 | ≤28 | ≤34 | |

Bulk density g/cm3 | 110°C*24h | ≥3.0 | ≥2.8 | ≥2.5 | ≥2.4 |

1000°C*3h | ≥2.9 | ≥2.8 | ≥2.5 | ≥2.4 | |

Modulus of repture Mpa | 110°C*24h | ≥12 | ≥10 | ≥8.5 | ≥7.0 |

1000°C*3h | ≥18 | ≥15 | ≥13 | ≥11 | |

Cold crushing strength MPA | 110°C*24h | ≥120 | ≥90 | ≥68 | ≥50 |

1000°C*3h | ≥180 | ≥120 | ≥95 | ≥80 | |

Linear change after burning% | 1000°C*3h | ±0.2 | ±0.2 | ±0.3 | ±0.3 |

Wear resistance(ASTMc-704) cm3 | ≤3.0 | ≤5.0 | ≤7.0 | ≤9.0 | |

Heat conductivity coefficient W/m.k | 1.6 | 1.5 | 1.5 | 1.5 | |

Thermal shock resistance(times)(1000°C water cooling | ≥35 | ≥30 | ≥25 | ≥20 | |

Refractoriness °C | ≥1790 | ≥1790 | ≥1750 | ≥1730 | |

Max working temperature °C | ≥1550 | ≥1500 | ≥1400 | ≥1350 | |

![]()

1.The items are better than we expected. Good. Thank you!---Philippines

2.Jacky,I want to inform We are very happy about the quality of the packing and personalization and we thank you for all the help and support.---Romania

3.Our client satisfied with the SK-32 fire bricks . But It would be better if the delivery time be shorter in our next order.---Korea

4.This is the first time for our cooperation. They are indeed what we want. We look forward to working with you again in the near future.---Algeria

5.we appreciate for your good products and service all the time. Thanks---Peru

6.Very good service and products all the time. Thank you.---Spain

![]()

1.Are you a manufacturer or trader?

Factory + trade (mainly factories, at the same time, we operates other related products)

2.Can we visit your factory?

Sure,welcome at any time,seeing is believing

3.what's the MOQ of trial order ?

No limit,We can offer the best suggestions and solutions according to your condition.

4.Which payment terms are you accept?

T/T,LC,Western Union,moneygram,Paypal are available for us.

5.After an order is placed, when to deliver?

15-25days

6.Is your company accept customization?

We have own factory and excellent technical team, and we accept OEM service.

7.How about your company's certification?

SGS,ISO9001 and Test Report,also we could apply other necessary certification.

8.how to solve the quality problems?

If the products are not conform to customer samples or have quality problems, our company will be responsible to make compensation for it.

- Q: Does anyone know the difference between refractory and thermal insulation material?

- I will give you a relatively simple analysis. Refractory can bear above 1,200 degrees centigrade, but some refractory is not insulated. For example, refractory brick can be directly in contact with heat source, but it has little insulation effect. Refractory includes ceramic fiber, high silica and so on. And they can be also insulated. But insulation effect is not so good as insulation material. Insulation material generally can bear below 800 degrees centigrade, and it is large in thermal resistance, low in heat conductivity coefficient and high in porosity factor, thus reducing heat loss. Briefly speaking, insulated material is to store most heat, and just let a small quantity of heat run of through air, thus insulating heat. Refractory includes glass fiber, rock wool, aerogel blanket and so on.

- Q: What are the physical properties of refractory material?

- The mechanical properties of refractory material include compressive strength, volume density and sclerosing, slag resistance, elastic modulus, thermal shock resistance, oxidation resistance, bibulous rate, fluidity, resilience, bond strength and slump, electrical conductivity, specific heat, heat capacity, the impact strength, linear change, torsional strength, stomatal aperture distribution, resistance to acid, etc. The use performance of refractory material include refractoriness, thermal emissivity, condensation, porosity, coefficient of thermal expansion. Thermal properties of refractory material include thermal conductivity, temperature conductivity, plasticity, the hydration resistance, creep performance. The physical properties of the refractory materials include structure performance, mechanical properties, shear strength, load softening temperature, CO erosion resistance. The structure properties of the refractory materials include porosity, alkali resistance and sintering. The operating performance of refractory material include consistency, tensile strength, the use performance and operating performance, wear resistance, bending strength, thermal properties.

- Q: Who knows about the fire endurance of sintered shaly hollow bricks?

- Sintered shaly hollow bricks of Chu area have high intensity. The average compressive strength of them is up to 15.8, which matches with M7.5 cement mortar that has advantages of low water absorption, and good anti efflorescence performance. The fire endurance of sintered shaly hollow bricks should not exceed1050 degrees otherwise they will burn excessively. I, actually, think that the temperature should be controlled within 980 degrees. I hope my answer may help you.

- Q: Who knows the external wall thermal insulation materials fire rating requirements?

- The requirements of Department of Housing and the Ministry of Public Security No. 46: Residential buildings: the height of building is greater than 100 meters, the combustion performance of insulation materials should be level A. The other civil buildings: 24≤ height

- Q: The principle of choosing fire-resistant material in Thermal Energy and Power Engineering equipment.

- Different thermal technology equipment has different operation condition and select different refractory material. We should take economical and practical as principle.

- Q: What are the components of refractory clay?

- The major raw material are bauxite, magnesite, silica, etc. It is easy to combine, high temperature resistant, corrosion resistant and has other advantages. It can be applied for refractory bricks in a variety of masonry.

- Q: What refractories can withstand high temperature above 2100 degrees?

- You can refer to advices from the first one coupled with the second one.

- Q: What kinds of fireproof materials does the safe use?

- The fireproof materials of safe, copper is one of the most widely used material of locks for its good mechanical performance, corrosion resistance and processibility and beautiful colors.

- Q: How is the development of Xinmi refractories industry? What's its advantages and disadvantages?

- I don't know how it has developed. Its advantage is the coal industry. You have to know the generating capacity in Xinmi thermal power plant first, and then you will know their coal cinder yield, after all, this is the raw material. Xinmi is not far away from Zhengzhou. The real estate in Zhengzhou is still good. I'm not sure about the others.

- Q: Refractory inquiries

- Special refractories are new inorganic non-metallic materials developed on the basis of traditional ceramics and refractory materials.

Send your message to us

Raw Materials for Refractory Insulating Castable Polyurethane Cement Refractory Cement

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords