HZS150 Concrete Batching Plant / ISO & CE

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The product is widely used in key projects like various highways, railroads, high-speed railways, airports, ports, bridges, and hydropower stations, as well as commercial concrete mixing station, real estate, and municipal construction. With constantly increasing investment in technological innovation, the company has achieved great achievements and been recognized as “Provincial Enterprise Technology Center” in 2008. The company has 4 research department respectively specializing in mixing, transportation, conveying, and automation.

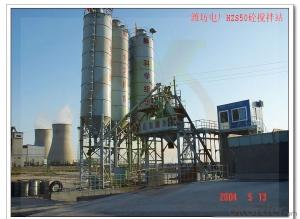

Concrete mixing plant HZS150

Theoretical productivity 150m3/h

Mixer model JS3000

Mixer nomination capacity 3000L

Mixing largest aggregate 100mm

Mixing motor power 2x55kw

Aggregate lifting belt motor power 45kw

Aggregate conveying belt width 1000mm

Aggregate lifting belt conveying capacity 600t/h

Aggregate batcher PL4800

Aggregate bin capacity 4x25m3

Aggregate batching capacity 4800L

Aggregate types 4

Powder bin capacity 50/100/200t(Optional)

Screw conveyor 60t/h

Aggregate measuring precision ±2%

Powder measuring precision ±1%

Water measuring precision ±1%

Additive measuring precision ±1%

Discharging height 3.8m

Power 200kw(Without screw conveyor)

Weight 100t(Without screw conveyor and cement bin)

- Q: What raw materials and equipment do you need for your own admixture?

- The main ingredients of admixtures are: the mother fluid, the composition of the air and the composition of the mixture, and the water. The concrete formulations are determined according to the different materials of concrete, which is usually the mother solution and the adjustment time. The parent fluid is itself well adapted and does not require a lot of material. Complex admixtures do not require any other equipment except for the geosyncline configuration.

- Q: What kind of sand do you need for a concrete plant? I don't know where to start!

- Which have so many requirements, sand silt content not too many, too many big rocks, soil, too much, artificial sand and river sand can, had better not use weathering sand, not according to the standard to which have the standard, is to see the skill of your lab

- Q: How much water does a concrete mixer use every day?

- Water is an indispensable part of the concrete production industry. As an investment company in a concrete mixing station, it is also important to have control over water use. It is also an aspect of production cost control. The use of water used in concrete stations is not the main water link. Flush the blender and cement truck every day to use a lot of water. The concrete is very difficult to handle because of the condensation. So it is the most effluent project in the production standstill. And the washings of these rinsing equipment contain water slurry, aggregates and aggregates, etc. From the environmental point of view, the water of cement mortar or concrete is strong alkaline, the PH value is high, can reach about 12, free discharge can pollute the environment. Therefore, with the continuous improvement of the environmental requirements in recent years, the waste water treatment of the mixing station becomes the main concern.

- Q: What does HZS mean in the HZS120 concrete mixing station

- Because building aggregate measurement compared with standing aggregate metering, reduced the four of the intermediate links, and the vertical blanking metering, saved measuring time, thus greatly improving the production efficiency, under the condition of the same model, mixing building production efficiency than mixing plant production efficiency by a third. Such as: HLS90 floor of production efficiency and production efficiency of HZS120 stand HLS120 floor of production efficiency, production efficiency is equivalent to HZS180 stand HLS180 floor of the production efficiency is equivalent to the productivity of HZS240 station.

- Q: What are the advantages of HZS series of concrete mixing stations

- Is economical and practical type of small and medium sized concrete mixing station mixing plant, usually more than township, built in the smaller areas, compared with large mixing station the installed it easier, and covers an area of small, transportation is convenient.

- Q: How much concrete is produced by the js1000 type of the concrete mixing station

- The JS1000 is only the mainframe model and depends on the power of the whole machine and the size of the batching machine. The JS1000 has HZS50, 60, 75, which is in theory, 50, 60 and 75 per hour. The actual operation is certainly less, about 80%

- Q: What is the special work of the concrete mixing station

- Mixer operator, welder, tester, loader driver's license, assessor

- Q: Concrete mixstations belong to no special equipment

- The boiler is a special equipment in the stirring station.

- Q: Which staff does the concrete mixing station need?

- Mainly depends on how much station, whether can fully staffed, mainly included: general manager, deputy general manager, technology, webmaster, laboratory (deputy) director of the general, the production manager, sales managers, salespeople, scheduling, lab team leader, the operator (inspection), quality inspection, proportioning design, the material inspector technicians, machine operators, resposible, site, monitor of overhaul, maintenance engineer, loadometer, finance, cashier, mixers, pump truck drivers, company drivers, forklift driver, the handyman, chef, etc.

- Q: The mixing time of the concrete mixer is in which standard

- Concrete quality control standard gb50164-2011

Send your message to us

HZS150 Concrete Batching Plant / ISO & CE

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords