Hydraulic Shock Sub of Type YJ Using in Oilfield

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 50 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Hydraulic Shock Sub of Type YJ Description

The Hydraulic Shock Sub type "YJ" is fully hydraulic and is used for reducing vibrations caused by hard formation drilling and keeping the drill bit firmly on the bottom, so that it helps to reduce drill string connection fatigue and prolong drill string life.

2. Main Features of Hydraulic Shock Sub of Type YJ

1) Advanced test for quality

2) MTC provided

3) Good price and service

3. Hydraulic Shock Sub of Type YJ Images

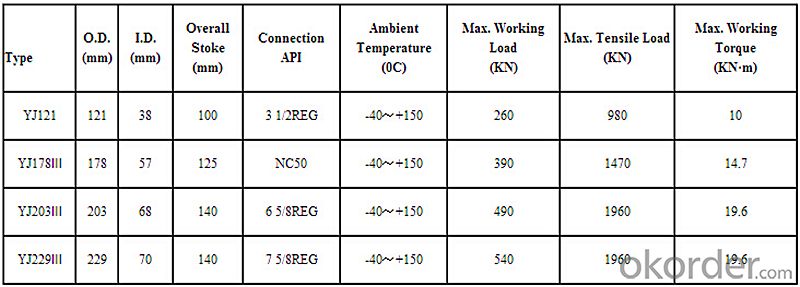

4. Hydraulic Shock Sub of Type YJ Specification

5. FAQ of Hydraulic Shock Sub of Type YJ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

One of the leading manufacturers and suppliers in China, mainly offering various of oilfield products consists of our one-stop sales. The integrated sales & service ensures customers with various demands an easier access for purchasing management.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: What is a gear pump for?

- Oil pump casing wearIt is mainly the wear of the floating sleeve hole (the normal clearance between the gear shaft and shaft sleeve is 0.09~0.175mm, and the maximum shall not exceed 0.20mm). The gear work is affected by the pressure oil, the gear tip is close to the oil pump casing, and the low pressure chamber part of the pump body is worn. Another kind of wear is the circumferential wear of the work surface in the shell. This kind of wear is mainly caused by the addition of oil which is not clear, so the oil without impurities is necessary.

- Q: What does "anti pump" mean in pump operation?

- The working process of the main oil cylinder pushing back and forth against the pump when the S valve (C valve or valve or gate valve skirt) reverse swing, so the piston suction concrete cylinder is in the ash conveying pipe is exactly opposite is the pump suction pump (hopper is concrete and push into the hopper, the desizing)

- Q: Pump unloading in hydraulic transmission,

- Unloading is pumping oil directly back to the tank, the pressure is very low, energy saving

- Q: Does vacuum pump oil belong to dangerous goods?

- Is the grease inside? How could it be dangerous goods? Absolutely not!

- Q: Fire control center manually start the fire pump directly, multi line control, called straight up line NHKVV-7*1.5, my understanding is: straight line from fire control center

- Multi line linkage NHBVR-4*1.5 is a positive pressure blower and smoke exhaust machine fire fighting equipment

- Q: How to install, operate and maintain the pipeline booster pump?

- When the pump leaks, check it immediately to prevent leakage. If it leaks with the motor connection, replace the mechanical seal. Check that the power is connected. Is the supply voltage consistent with the operating voltage of the pump?. If the above a and B are normal, please remove the pump, open the pump cover, remove the foreign body in the pump, and then pump the lid on, and then tighten it to normal.No water pump, pump installed in the tap water pipeline, such as tap water level in the pump impeller on the plane (horizontal installation) or center line (vertical) below, you should turn off the power supply, to tap water level rise more than the impeller plane or the center line, connected to the power supply, to avoid mechanical damage (automatic no need to turn off the electric type). When the pump used in pumping wells, please check whether the water inlet pipe leak; pump cavity storage is not enough, should be filled with water, whether the suction process is too high, proper adjustment. Check whether the inlet and outlet diameter is too small or blocked. Automatic type after a period of time, there may be automatic failure phenomenon, mainly stainless steel and other metal products in pipes, long-term precipitation to shut off the power supply after unloading, unscrew the top screw, remove the plastic sheet to be cleaned, and then, according to the original reset, the normal debugging, can be re used.

- Q: What is the lift off the dead center point? This is a straight mark about the water pump. What is the function and the relationship between the design head and the pump head? ThanksWhat exactly is the dead point lift? What's the function of this indicator?

- In a dead head will be relatively high, the main downstream equipment and pump, if a dead head high, so the design pressure of the pump needs downstream equipment will be relatively large, resulting in the cost increases, so close a better head lower dead point.

- Q: What are the basic technical parameters of the pump?

- Two, pump head H head is the unit weight of the liquid pump pumping from the inlet of the pump (pump inlet flange) to the outlet of the pump (pump outlet flange) energy value. Effective energy is a Newtonian liquid through the pump unit is obtained. The N m/N=m, the height of liquid column pumping liquid. Habits referred to as meters. Three, the pump speed is n RPM pump unit time revolutions, represented by the symbol n, the unit is r/min. four, the pump NPSH NPSH NPSH is also called net positive suction head, said main parameters of cavitation performance. Cavitation has been used a h power of five, the power of the pump. And the efficiency of the pump is usually refers to the input power, which is the prime mover on the pump shaft power, it is also known as the shaft power, denoted by P;

- Q: Why is the sewage pump device coupler?

- The automatic coupling device but the installation of GAK type submersible sewage pump, need lifting, people may not need to unscrew the screw water, the water pump can directly improve, after repairing down along the guide rail can realize sealing pump and pipeline, water pump and normal operation. Small sewage pump can be installed freely, large sewage pumps are generally equipped with automatic coupling device, automatic installation, installation and maintenance is very convenient.

- Q: Why is the submersible pump tripped on an electrical switch?There is no electrical leakage protection, directly connected to the circuit breaker, and when the switch on, the circuit breaker jumpedI checked the line is good, the pump did not break down, is not the water pump?

- Calculate or refer to the water pump nameplate that the normal operating current, according to this data exchange switch.2) with 500V shaking table, measuring the cable, motor insulation is in line with the requirements

Send your message to us

Hydraulic Shock Sub of Type YJ Using in Oilfield

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 50 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches