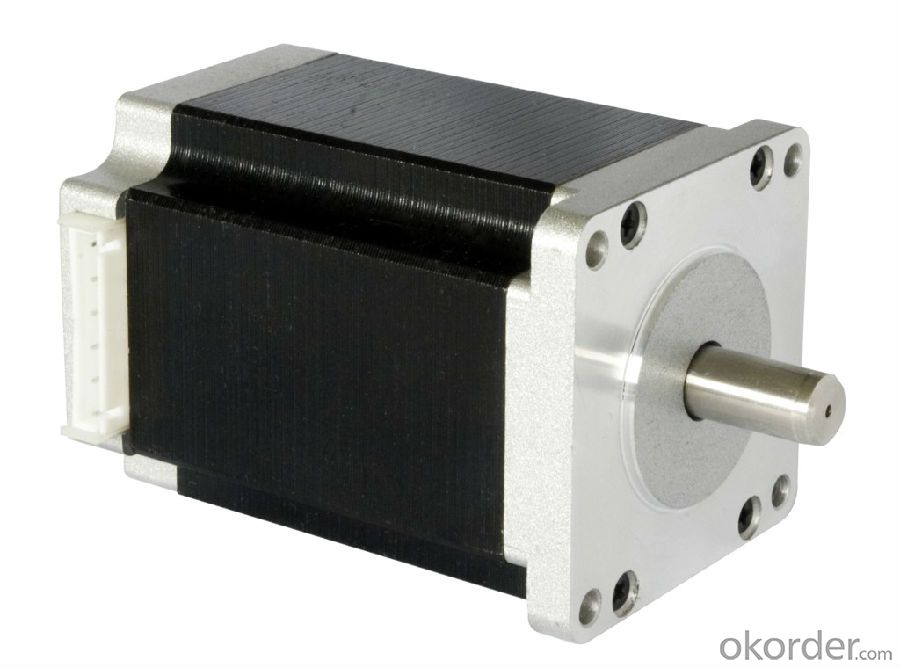

Hybrid Stepper Servo Motor Hs421 (42mm, 2Phase)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 2500 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Hybrid Stepper Servo Motor Hs421 (42mm, 2Phase)

Product Details

Basic Info.

Model NO.:HS421(1.8degree )42mm-2 Phase

Excitation Mode:HB-Hybrid

Type:Magnetic-Electric

Size:42mm

Speed:0-3000rpm

Resistance:100min 500VDC

Tem.:0-55

Export Markets:Global

Additional Info.

Trademark:I. CH

Standard:CE, RoHS, nqa

Origin:Nanjing China

Production Capacity:50, 000PCS/Year

Product Description

I.CH Motion Hybrid Stepper Servo Motor HS421

General Specifications

Speed:0-3000RPM

Insulation Resistance:100MIN,500VDC

Ambient Temperature:(0-55ºC

Encoder lines:2500/1000

| Electrical Specification | ||||||||

| Series Model | Rated Voltage (V) | L (mm) | Phase Current (A) | Phase Resistance (Ω) | Phase Inductance(mH) | Holding Torque (N.cm) | Moment of Inertia (g.cm2) | Motor Weight ( g) |

| HS421-05013A | 4.16 | 51 | 1.3 | 3.2 | 5.5 | 50 | 77 | 530 |

| HS421-05023A | 2.3 | 51 | 2.3 | 1.0 | 1.9 | 50 | 77 | 530 |

| HS421-05613A | 4.94 | 67 | 1.3 | 3.8 | 8.5 | 56 | 115 | 670 |

| HS421-07023A | 3.22 | 67 | 2.3 | 1.4 | 3.1 | 70 | 115 | 670 |

- Q: The maximum surface temperature of the step motor is permissible

- The effects of fever Electric motor fever, although not normally affecting the life of the motor, is not necessary for most customers. However, severe fever can have some negative effects. Internal parts such as motor thermal expansion coefficient of different lead to the change of structural stress and internal air gap of tiny change, affects the dynamic response of the motor, high speed will be easy to out of step. In some cases, excessive heating of electric motors, such as medical devices and high-precision testing equipment, are not allowed. Therefore, the heating of the motor should be controlled.

- Q: What are the advantages and disadvantages of stepping motor? What occasion does it apply to?

- Disadvantages: If the control is not easy to generate resonance; It is difficult to operate at a high speed. The main application is: First, the stepper motor is mainly used in some places that have requirements of positioning requirements, such as: wire cutting workbench drag, flocking machine workbench (pores), packaging machine (length), basically involves positioning occasions are applied;

- Q: This paper summarizes the characteristics and advantages and disadvantages of the stepper motor motor

- Step Angle: corresponding to a pulse signal, the angular displacement of the rotor of the motor is expressed in theta. Theta = 360 degree (the number of rotors), in the case of the normal two and four phases, the rotor teeth are 50 teeth motor. Four run time interval Angle is theta = 360 degrees/(50 * 4) = 1.8 degrees (commonly known as a whole step), eight beats runtime interval Angle is theta = 360 degrees/(50 * 8) = 0.9 degrees (commonly known as half step). These two concepts clearly, after we again to calculate the rotational speed, with basic steps within 1.8 ° Angle of stepping motor as an example (now in the market of conventional two, four basic steps from the Angle of the hybrid stepping motor is 1.8 °), four phase eight running mode, each receives a pulse signal, around 0.9 °, if receive 400 pulses every second, so speed is 400 megabits per second x0. = 9 ° 360 °, equivalent to turn every second, every minute 60. Other things can be calculated.

- Q: What is the maximum speed that a step motor can achieve?

- Stepper motor can run under no-load condition 3000 RPM, but at this time of the output torque is very small, there is no application value, for a specific design, stepper motor can run, high main reference step torque frequency curve, as long as the motor output torque can meet the application requirements, high speed can be as much as possible. In addition, it is important to consider whether or not the bearings are suitable for high speed.

- Q: How to control the step motor with s7-200, how to control the yield to the motor, how to stop?

- Use the continuous pulse output command (speed control instruction) from the s7-200. Stop also using the instructions, detailed in your instruction manual for Siemens.

- Q: The type and calculation method of stepping motor?

- When stepping into the motor, the first step is to ensure that the output power of the step motor is greater than that of the load. And when choosing power stepping motor, first to compute the mechanical system of load torque, the torque of the motor frequency characteristics can satisfy the mechanical load and has a certain margin to ensure its reliable operation. During the actual working process, the load torque at various frequencies must be within the range of the moment frequency characteristic curve. Generally speaking, the maximum static moment Mjmax is large, and the load torque is large.

- Q: What are the advantages of servo motors compared to stepper motors?

- The servo is closed loop, high precision, and can be made faster and more powerful.

- Q: What is the step in the step motor

- Analysis of stepping and missing steps of stepping motor: Step 1: in the wrong type of motor, the inertia of the motor moment is not enough, or the inertia of the motion of the object exceeds the self-locking force of the motor, causing the lost step or the lost step 2: drive improper selection, form a complete set of drive current is small, affect the normal operation of motor, now on the market a lot of drive current virtual target, take a peak current when the rated current to fool consumers, drive type rated current should be greater than stepper motor 1.2 1.5 times rated current

- Q: What are the six wires of the step motor

- Stepper motor wiring has 4 lines, six lines and eight wire, line 4 is the most simple of A and B phase winding wire, 8 wire mainly to customers convenient application design, if the user needs to run will be used on high speed parallel connection mode, if the user is mainly used in low speed high torque circumstance, can be used in series connection mode, 6 line mainly is suitable for single polarity control applications, if the drive is not A single polarity drive, you can tap the middle line dangling don't can, at this moment motor series work mode

- Q: The current and voltage of the step motor, inductance

- The torque size is directly related to the winding number of current and winding; In the case of constant current, the more winding number (and the greater the inductance), the greater the torque. So you understand that the torque = winding number x current understanding can be used to refer to this formula, but it's not, it's a lot more complicated than this formula. High-speed cases, i.e., voltage frequency conversion quickens, winding back emf get bigger, abate forward current, so the speed of the motor torque will be smaller. As for the problem, I can't sure answer, I analysis is that the high frequency, inductance is big, the greater the current weakening, winding circle number is the same, so the inductor motors when high speed low torque.

Send your message to us

Hybrid Stepper Servo Motor Hs421 (42mm, 2Phase)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 2500 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches