HRB400 Tianjin Steel Rebar Manufacturer Supply Deformed Steel Rebar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

AISI,ASTM,JIS,GB,BS,DIN,API,EN

Technique:

Hot Rolled,Cold Rolled,Cold Drawn,ERW,Forged,Saw,Extruded,EFW,Spring

Shape:

U Channel,Square,C Channel,Hexagonal,Round,Rectangular,Oval,LTZ

Surface Treatment:

Galvanized,Coated,Copper Coated,Color Coated,Oiled,Dry,Chromed Passivation,Polished,Bright,Black,PVDF Coated

Steel Grade:

Q195,Q215,Q235,Q215B,Q235B,RHB335,HRB400,200 Series,300 Series,400 Series,600 Series,SS400-SS490,10#,20#,A53(A,B)

Certification:

ISO,SGS,BV,IBR,RoHS,CE,API,BSI,UL

Thickness:

6-34mm

Width:

6-34mm

Length:

12m

Outer Diameter:

6-34mm

Net Weight:

10kg

Packaging:

seaworthy packaging

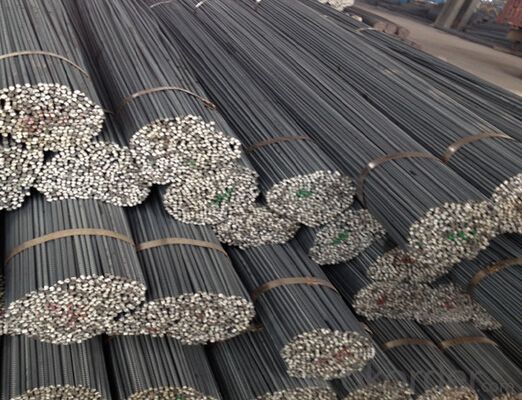

HRB400 Tianjin Steel Rebar Manufacturer Supply Deformed Steel Rebar

Details of the HRB400 Tianjin Steel Rebar Manufacturer Supply Deformed Steel Rebar

| Standard & Grade: | GB1499-98 : HRB335,HRB400,HRB500 |

| BS4449-1997 : GR460,GR500 | |

| CAN/CSA-G30.18-M92 : 400W | |

| ASTM A615 : Gr.40, Gr.60 | |

| Diameter: | 6mm;8mm;10mm;12mm;14mm;16mm;18mm;20mm;22mm;25mm;28mm;30mm;32mm;35mm;40mm |

| Length: | 6m,9m,12m |

| Packing: | Bundle packing |

| Origin: | China |

| Application: | Construction,Road,Machinery processing,Welding fields. |

| Delivery time: | 10-25 days |

| Shipment: | By bulk vessel or Container |

| Documents: | Mill Test Certificate,Commercial Invoice,Packing List,Certificate of Origin |

Company Introduction of the HRB400 Tianjin Steel Rebar Manufacturer Supply Deformed Steel Rebar

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of the HRB400 Tianjin Steel Rebar Manufacturer Supply Deformed Steel Rebar

| Packaging Detail | Sea worthy packing /as per customer's packing instruction |

| Delivery Detail | 15 ~ 40 days after receiving the deposit |

FAQ

| Are you a trading company or manufacturer? | Manufacturer |

| What’s the MOQ? | 1000m2 |

| What’s your delivery time? | 15-20 days after downpayment received |

| Do you Accept OEM service? | Yes |

| what’s your delivery terms? | FOB/CFR/CIF |

| What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

| Western Union acceptable for small amount. | |

| L/C acceptable for large amount. | |

| Scrow ,Paybal,Alipay are also ok | |

| Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

| What's your available port of Shipment? | Main Port, China |

| What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust |

| Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the design considerations for using steel rebars in construction?

- Some important design considerations for using steel rebars in construction include the required strength and load-bearing capacity, corrosion resistance, compatibility with other construction materials, durability, and ease of installation. Steel rebars should be chosen based on their appropriate diameter, grade, and spacing to ensure structural integrity and safety. Additionally, proper detailing and placement of rebars are essential to ensure that they are effectively embedded within concrete and can withstand the anticipated stresses and forces during construction and throughout the lifespan of the structure.

- Q: What are the main uses of threaded steel?

- The difference between round bar and round bar is that the surface has longitudinal ribs and transverse ribs, usually with two longitudinal ribs and transverse ribs uniformly distributed along the length direction.

- Q: What is the role of steel rebars in ensuring occupant safety?

- The role of steel rebars in ensuring occupant safety is crucial as they provide strength, stability, and reinforcement to concrete structures. By reinforcing concrete with steel rebars, they enhance the structural integrity of buildings, bridges, and other infrastructure, making them more resistant to external forces such as earthquakes, heavy loads, and impacts. Steel rebars help prevent the collapse of structures, reducing the risk of injury or fatality to occupants during unexpected events or accidents.

- Q: How are steel rebars measured?

- Steel rebars are measured using a standardized system known as the "bar size number." This system assigns a numerical value to each rebar size, which corresponds to the diameter of the rebar. The diameter is measured in inches or millimeters, depending on the region or country. In the United States, the bar size number is used, which ranges from #3 to #18. The number indicates the diameter of the rebar in eighths of an inch. For instance, a #3 rebar has a diameter of 3/8 inch, while a #8 rebar has a diameter of 1 inch. Beyond #8, the diameter is measured in quarters of an inch. For example, a #11 rebar has a diameter of 1 1/8 inches, and a #18 rebar has a diameter of 2 1/4 inches. In metric countries, rebars are measured using millimeters. The diameter is typically rounded to the nearest millimeter. For instance, a 10 mm rebar is equivalent to a #3 rebar in the US, and a 25 mm rebar is equivalent to a #8 rebar. To measure the length of a rebar, a tape measure or ruler is used. The length is typically measured in feet or meters. Rebars are commonly available in lengths of 20 or 40 feet (6 or 12 meters), but they can also be cut to custom lengths as per project requirements. It is important to note that the measurement system may vary slightly in different regions or countries, so it is crucial to consult local standards and codes for accurate measurement guidelines.

- Q: Can steel rebars be prefabricated off-site?

- Yes, steel rebars can be prefabricated off-site. Prefabrication involves manufacturing and assembling components, including rebars, in a controlled environment away from the construction site. This method offers numerous advantages, such as improved quality control, reduced construction time, and increased efficiency. Prefabricated steel rebars can be customized, cut, bent, and welded to meet specific project requirements before being transported to the construction site for installation.

- Q: Can steel rebars be used in structures with long spans?

- Yes, steel rebars can be used in structures with long spans. Steel rebars are commonly used as reinforcement in concrete structures, including those with long spans such as bridges, high-rise buildings, and stadiums. The high tensile strength and durability of steel rebars make them suitable for withstanding the forces and stresses that occur in such structures.

- Q: Are steel rebars suitable for use in high-rise buildings?

- Yes, steel rebars are suitable for use in high-rise buildings. Steel rebars provide excellent strength, durability, and flexibility, making them ideal for reinforcing concrete structures in high-rise buildings. Their ability to resist tensile forces and bond with concrete ensures the structural integrity and stability required in tall buildings.

- Q: How do steel rebars help in load distribution within a structure?

- Steel rebars, also known as reinforcing bars, play a crucial role in load distribution within a structure. They are extensively used in concrete structures, such as buildings, bridges, and highways, to enhance their strength and durability. The primary purpose of steel rebars is to provide tensile strength to the concrete. While concrete is excellent in compression, it is relatively weak in tension. Any structure subjected to loads, whether from the weight of the building itself or external forces, will experience both compression and tension forces. By placing steel rebars within the concrete, they act as reinforcement and resist tensile forces. When an external load is applied to the structure, the rebars carry a significant portion of the tension forces generated. This prevents the concrete from cracking or failing under the applied load. Moreover, steel rebars help in distributing the load throughout the structure. When a load is applied to a structure, it creates stress that is distributed across the various components. The presence of rebars allows for a more even distribution of these stresses, reducing the concentration of forces in specific areas. This prevents localized failures and ensures that the load is evenly dispersed across the structure, improving its overall strength and stability. Another important aspect of steel rebars is their ability to bond with concrete. The rough surface of the rebars prevents them from slipping or separating from the concrete, ensuring a strong bond between the two materials. This bond further enhances the load distribution by allowing the rebars to effectively transfer the tensile forces to the surrounding concrete. In summary, steel rebars play a vital role in load distribution within a structure. They provide the necessary tensile strength to resist tension forces, distribute the load evenly across the structure, and bond with the concrete, ensuring a robust and stable construction. Without steel rebars, concrete structures would be significantly weaker and more susceptible to cracking or failure under load.

- Q: Can steel rebars be used in the construction of theme parks and entertainment venues?

- Yes, steel rebars can be used in the construction of theme parks and entertainment venues. Steel rebars are commonly used in construction projects to reinforce concrete structures, providing strength and durability. In the case of theme parks and entertainment venues, where large crowds gather and safety is paramount, steel rebars can help ensure the structural integrity of buildings, rides, and other facilities.

- Q: How do steel rebars affect the overall creep and shrinkage of concrete structures?

- Steel rebars have a significant influence on the overall creep and shrinkage of concrete structures. The presence of rebars helps to control and minimize the shrinkage of concrete by providing restraint and reducing the amount of drying shrinkage. Additionally, rebars contribute to the overall stiffness of the structure, decreasing the potential for creep deformation over time. Therefore, steel rebars play a crucial role in mitigating both creep and shrinkage in concrete structures, ensuring their stability and durability.

Send your message to us

HRB400 Tianjin Steel Rebar Manufacturer Supply Deformed Steel Rebar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords