Hrb400 Deformed Steel Bar Supplier from Tianjin

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hrb400 Deformed Steel Bar Supplier from Tianjin

Description of Hrb400 Deformed Steel Bar:

1, Diameter: 5.5mm-10mm rounds Hrb400 deformed steel bar

10m- 40mm Hrb400 deformed steel bar

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

Chemical Composition of Hrb400 Deformed Steel Bar:

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

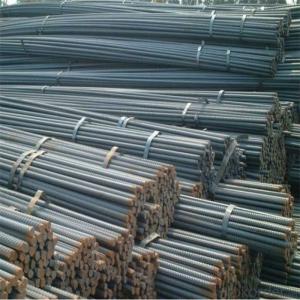

Product Show of Hrb400 Deformed Steel Bar:

Company Information:

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ:

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

- Q: What are the most common alloys used in special steel?

- The most common alloys used in special steel include stainless steel, tool steel, and high-speed steel.

- Q: What are the key alloying elements used in special steel?

- The key alloying elements used in special steel are typically chromium, nickel, molybdenum, vanadium, and tungsten. These elements are added in varying proportions to enhance specific properties such as corrosion resistance, strength, hardness, and heat resistance, making special steel suitable for various applications in industries like aerospace, automotive, and construction.

- Q: How are nickel-based alloys used in the aerospace industry?

- Nickel-based alloys are extensively used in the aerospace industry due to their superior strength, high temperature resistance, and excellent corrosion resistance properties. These alloys are commonly employed in the construction of aircraft engines, turbine blades, and exhaust systems. They help improve engine efficiency, enhance fuel economy, and ensure safe and reliable operations in extreme conditions, making them crucial for the advancement of aerospace technology.

- Q: How does special steel perform in extreme heat conditions?

- Special steel is specifically designed to perform exceptionally well in extreme heat conditions. It exhibits high resistance to thermal fatigue, oxidation, and creep, making it suitable for applications that involve exposure to intense heat. The unique composition and processing techniques used in the production of special steel allow it to retain its mechanical properties and structural integrity even at elevated temperatures. One of the key characteristics of special steel is its high melting point, which prevents it from melting or deforming easily under extreme heat. This property is crucial in industries such as aerospace, power generation, and automotive, where components are subjected to intense heat and need to maintain their shape and functionality. Furthermore, special steel possesses excellent heat resistance, meaning it can withstand and dissipate heat effectively without losing its strength or becoming brittle. This property ensures that the steel remains durable and reliable even when exposed to prolonged high-temperature environments. Special steel also exhibits outstanding oxidation resistance, forming a protective layer on its surface that prevents it from corroding or degrading when exposed to oxygen at high temperatures. This resistance to oxidation allows special steel to maintain its performance and structural integrity over extended periods, making it highly suitable for applications in extreme heat conditions. In summary, special steel performs exceptionally well in extreme heat conditions due to its high melting point, heat resistance, and oxidation resistance. Its ability to withstand thermal fatigue, oxidation, and creep makes it a reliable and durable choice for applications that require superior performance in high-temperature environments.

- Q: What are the applications of special steel in the automotive supply chain?

- Special steel has various applications in the automotive supply chain. It is commonly used in the manufacturing of critical components such as engine parts, suspension systems, and transmission gears. The high strength, durability, and heat-resistance properties of special steel make it suitable for these applications, ensuring optimal performance and safety in vehicles. Additionally, special steel is also utilized in the production of specialized tools and equipment used in automotive manufacturing processes.

- Q: What are the different methods of surface carburizing for special steel?

- Some of the different methods of surface carburizing for special steel include pack carburizing, gas carburizing, liquid carburizing, and plasma carburizing.

- Q: What are the main characteristics of structural steel forgings?

- Structural steel forgings offer numerous advantageous qualities that make them highly suitable for a wide range of construction and engineering purposes. To begin with, the outstanding strength and durability of structural steel forgings are among their main attributes. Steel possesses remarkable tensile strength, allowing it to bear heavy loads and withstand stress-induced deformations. This makes structural steel forgings ideal for supporting large structures and withstanding dynamic forces such as wind or seismic activity. Another noteworthy quality is the versatility of structural steel forgings. Steel can be shaped and sized into a diverse array of forms, making it adaptable to various design requirements. It can be forged into intricate and complex shapes, enabling the creation of precise and customized components. This versatility enables the application of structural steel forgings in a multitude of scenarios, ranging from beams and columns in buildings to bridges and offshore structures. Moreover, structural steel forgings exhibit excellent weldability. Various welding techniques can be employed to easily join steel components together, creating robust and dependable connections. This enhances the overall structural integrity and longevity of steel elements. One more key characteristic of structural steel forgings is their cost-effectiveness. Steel is an economical construction material due to its abundance, recyclability, and ease of manufacturing. The production process for steel forgings is efficient and can be scaled up to meet the demands of large-scale construction projects. Consequently, it represents a cost-effective choice for numerous applications. Furthermore, structural steel forgings are renowned for their resistance to corrosion. Steel can be treated with coatings or alloys to enhance its resistance against rust and other forms of corrosion. This makes it highly suitable for deployment in environments with high humidity, exposure to saltwater, or harsh weather conditions. In conclusion, the exceptional strength, versatility, weldability, cost-effectiveness, and resistance to corrosion are the primary characteristics of structural steel forgings. These qualities position structural steel forgings as the preferred choice for a multitude of construction and engineering applications, offering durability, reliability, and longevity to structures.

- Q: Can special steel be used in the aerospace defense industry?

- Yes, special steel can be used in the aerospace defense industry. Special steel alloys such as high-strength steels, stainless steels, and nickel-based alloys are commonly utilized in the production of various components and structures for aerospace defense applications. These materials offer excellent mechanical properties, corrosion resistance, and durability, making them suitable for critical applications in the aerospace defense industry.

- Q: How is special steel used in toolmaking?

- Special steel is widely used in toolmaking due to its exceptional properties that make it highly suitable for creating durable and high-performance tools. Toolmaking involves the manufacturing of various tools such as drills, saws, cutting tools, dies, and molds, among others. Special steel is utilized in toolmaking to ensure that these tools possess the necessary strength, hardness, toughness, and wear resistance required for their intended applications. One of the primary advantages of special steel in toolmaking is its high strength. Special steel is alloyed with elements such as chromium, molybdenum, vanadium, and tungsten, which enhance its strength and hardness. This enables the tools to withstand heavy loads, resist deformation, and maintain their structural integrity even under extreme working conditions. In addition to strength, special steel also exhibits excellent hardness. Tools made from special steel undergo heat treatment processes such as quenching and tempering to achieve the desired hardness level. This hardness is crucial for toolmaking as it enables the tools to efficiently cut, drill, or shape various materials without getting damaged or worn out easily. Furthermore, special steel possesses exceptional toughness. Toughness refers to a material's ability to absorb energy and resist cracking or fracturing. Tools made from special steel can withstand impact and heavy loads, ensuring that they do not break or chip easily during use. This is particularly important in toolmaking as tools often encounter high-stress situations where toughness is vital to prevent premature failure. Another significant advantage of special steel in toolmaking is its excellent wear resistance. Tools are subjected to constant friction, abrasion, and contact with hard materials, leading to wear and tear. Special steel is specifically designed to resist wear, enabling the tools to maintain their cutting or shaping abilities over extended periods. This not only prolongs the tool's lifespan but also ensures consistent performance and high-quality output. Special steel is also known for its corrosion resistance, which is beneficial in toolmaking, especially when working with corrosive materials or in harsh environments. The inclusion of certain elements like chromium in special steel enhances its resistance to corrosion, preventing rust and deterioration of the tools. In conclusion, special steel plays a crucial role in toolmaking by providing the necessary strength, hardness, toughness, wear resistance, and corrosion resistance. These properties enable the tools to perform effectively and efficiently, ensuring durability and longevity. Whether it is for cutting, drilling, shaping, or molding, special steel is an essential material in the production of high-quality tools that meet the demands of various industries.

- Q: Can special steel be used for making chemical processing equipment?

- Yes, special steel can be used for making chemical processing equipment. Special steels, such as stainless steel, are often preferred for such applications due to their excellent corrosion resistance, high temperature resistance, and durability. Chemical processing equipment often deals with corrosive substances or operates at high temperatures and pressures, making it essential to use materials that can withstand these conditions. Special steel alloys are specifically designed to have superior resistance to corrosion, including resistance to acids, alkalis, and other aggressive chemicals. Additionally, these steels can maintain their mechanical properties even at elevated temperatures, ensuring the integrity and safety of the equipment. Therefore, special steel is a suitable choice for making chemical processing equipment.

Send your message to us

Hrb400 Deformed Steel Bar Supplier from Tianjin

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords