HRB400 High Tensile Rebars for Building Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

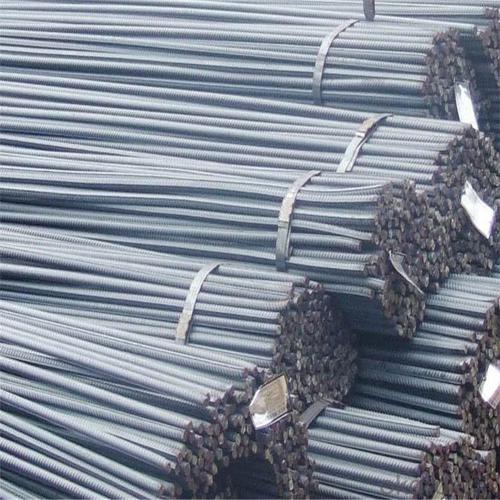

HRB400 High Tensile Rebars for Building Material

Description of HRB400 High Tensile Rebars for Building Material

1, Diameter: 5.5mm-10mm HRB400 High Tensile Rebars for Building Material

10m- 40mm HRB400 High Tensile Rebars for Building Material

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition of HRB400 High Tensile Rebars for Building Material

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

Products Show of HRB400 High Tensile Rebars for Building Material

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the different types of coatings for special steel?

- There are several types of coatings that can be applied to special steel to enhance its performance and protect it from various environmental factors. Some of the common types of coatings for special steel include: 1. Zinc-based coatings: These coatings, such as galvanized steel, provide excellent corrosion resistance. The zinc layer acts as a sacrificial barrier, protecting the underlying steel from rusting. 2. Epoxy coatings: Epoxy coatings are highly resistant to chemicals, moisture, and abrasion. They are often used in industries where the steel is exposed to harsh conditions or corrosive substances. 3. Powder coatings: Powder coatings offer a durable and attractive finish to special steel. They are applied as a dry powder and then cured under heat, forming a hard, protective layer that is resistant to chipping, fading, and corrosion. 4. Ceramic coatings: Ceramic coatings are known for their high-temperature resistance and excellent thermal insulation properties. They are often used in applications where the steel is exposed to extreme heat or rapid temperature changes. 5. Organic coatings: Organic coatings, such as acrylics and polyurethanes, provide a protective barrier against moisture, UV radiation, and chemicals. They are commonly used in outdoor applications, such as architectural structures or automotive parts. 6. Phosphate coatings: Phosphate coatings are primarily used as a pre-treatment before applying other coatings or paints. They improve adhesion and corrosion resistance of subsequent layers, providing a more durable finish. 7. Polymer coatings: Polymer coatings offer excellent resistance to abrasion, impact, and chemicals. They are commonly used in industrial settings where steel is subject to heavy wear and tear. It is important to select the appropriate type of coating based on the specific requirements of the special steel and the environment it will be exposed to. Each coating type has its own set of advantages and limitations, so a thorough analysis should be conducted to determine the most suitable option.

- Q: How is shock-resistant alloy steel used in the production of impact-resistant parts?

- Shock-resistant alloy steel is used in the production of impact-resistant parts due to its high strength and ability to withstand sudden impact forces without fracturing or deforming. This steel is specifically designed to absorb and disperse energy, making it ideal for applications where parts are exposed to repeated impacts or high-stress environments. By using shock-resistant alloy steel, manufacturers can create durable and reliable impact-resistant parts that can withstand heavy loads, reduce the risk of failure, and increase the overall safety and longevity of the component or equipment.

- Q: How does special steel contribute to improving product performance under extreme conditions?

- Special steel contributes to improving product performance under extreme conditions by offering enhanced strength, durability, and resistance to corrosion, heat, and wear. Its unique composition and advanced manufacturing techniques make it capable of withstanding high pressure, extreme temperatures, and harsh environments. This ensures that products made with special steel can perform reliably and efficiently, even in the most challenging conditions, thereby enhancing overall performance and extending their lifespan.

- Q: What are the main characteristics of alloy steel?

- Alloy steel, which is produced by incorporating specific elements like chromium, nickel, or molybdenum into iron, possesses distinct properties and qualities. Some key features of alloy steel are as follows: 1. Remarkable strength: Alloy steel is renowned for its exceptional strength. The introduction of alloying elements enhances its capacity to endure high pressures and heavy loads, making it an ideal choice for applications necessitating a robust and long-lasting material. 2. Enhanced hardness: Alloy steel is also recognized for its hardness, surpassing that of regular carbon steel. This attribute renders it resistant to wear, abrasion, and deformation, making it suitable for applications that require resistance to impact or wear, such as the production of cutting tools or machinery components. 3. Resistance to corrosion: Depending on the specific alloying elements employed, alloy steel can display excellent resistance to corrosion. For instance, the addition of chromium is a common practice to create stainless steel, which exhibits high resistance to rust and corrosion. This attribute positions alloy steel as a preferred material in industries where exposure to moisture or corrosive environments is prevalent. 4. Heat endurance: Alloy steel possesses the ability to withstand high temperatures without compromising its strength or structural integrity. The inclusion of elements like nickel, molybdenum, or vanadium augments its resistance to thermal expansion, oxidation, and softening at elevated temperatures. This quality renders alloy steel suitable for applications in the aerospace, automotive, and power generation sectors. 5. Versatility: Alloy steel is a versatile material that can be readily tailored to meet specific requirements. Manufacturers can create alloy steel with a broad range of properties, such as improved ductility, toughness, or electrical conductivity, by modifying the composition and proportions of alloying elements. This adaptability permits the utilization of alloy steel in diverse industries, encompassing construction, manufacturing, and engineering. In conclusion, alloy steel exhibits high strength, hardness, corrosion resistance, heat endurance, and versatility. These characteristics establish alloy steel as the preferred choice for a wide array of applications that demand a sturdy, durable, and dependable material.

- Q: How is special steel used in the manufacturing of consumer goods?

- Special steel is used in the manufacturing of consumer goods due to its exceptional properties such as high strength, durability, and corrosion resistance. It is utilized in various products like kitchen appliances, tools, automotive parts, and electronics, enhancing their performance and increasing their lifespan.

- Q: What is the cost of special steel compared to other materials?

- The cost of special steel can vary depending on various factors such as the type of steel, its composition, and market conditions. Generally, special steel tends to be more expensive than common materials like carbon steel or aluminum due to its unique properties and specialized manufacturing processes. However, it is important to consider that the cost of materials is just one aspect of the overall cost of a project, as factors like durability, performance, and maintenance requirements also play a significant role in the decision-making process.

- Q: How does special steel contribute to reducing product costs?

- Special steel contributes to reducing product costs in several ways. Firstly, special steel is known for its high strength and durability, which allows manufacturers to design and produce products that have a longer lifespan. This reduces the need for frequent replacements or repairs, thus saving costs in the long run. Additionally, special steel can be customized to meet specific requirements, allowing for the production of lighter and more efficient products. This can lead to savings in terms of raw material usage, transportation costs, and energy consumption. Moreover, special steel often has excellent corrosion resistance, reducing the need for additional protective coatings or maintenance, which can also result in cost savings. Overall, the utilization of special steel in manufacturing processes helps optimize product performance, longevity, and efficiency, thereby contributing to reducing product costs.

- Q: What are the requirements for special steel used in high-temperature applications?

- To ensure optimal performance and durability in extreme conditions, special steel utilized in high-temperature applications, such as aerospace, power generation, and oil and gas industries, must fulfill specific criteria. Some essential requirements for this type of steel include: 1. Excellent strength and resistance to deformation at elevated temperatures are vital for maintaining structural integrity and preventing failure or deformation under extreme heat. 2. High resistance to oxidation is necessary to prevent the formation of oxides on the steel's surface, which can weaken its structure and compromise its performance. 3. Exceptional creep resistance is essential to prevent excessive deformation or failure over time caused by constant stress at high temperatures. 4. Good thermal stability allows the steel to retain its mechanical properties even after prolonged exposure to high temperatures, ensuring reliable and consistent performance. 5. In addition to oxidation, the steel must also possess good corrosion resistance to protect against various corrosive agents present in the environment, such as acids, alkalis, and salts. 6. High resistance to thermal fatigue is crucial to prevent cracking, fracturing, or failure due to repeated heating and cooling cycles. 7. Low thermal expansion minimizes dimensional changes and maintains dimensional stability under high-temperature conditions, preventing unwanted distortions or misalignments. 8. Good weldability facilitates the fabrication and joining of components, enabling the construction of complex structures and assemblies required in high-temperature environments. By meeting these requirements, special steel used in high-temperature applications can withstand extreme heat, preserve its structural integrity, and deliver reliable performance in demanding conditions.

- Q: Can special steel be machined easily?

- No, special steel is typically harder and tougher than standard steel, making it more difficult to machine.

- Q: How are magnesium alloys used in lightweight structures?

- Magnesium alloys are used in lightweight structures due to their exceptional strength-to-weight ratio. These alloys offer high strength and stiffness while being significantly lighter than other metals like steel or aluminum. This makes them ideal for applications in sectors such as aerospace, automotive, and sports equipment, where weight reduction is crucial without compromising structural integrity. Additionally, magnesium alloys possess good vibration damping properties, corrosion resistance, and excellent machinability, making them even more advantageous for lightweight structure design.

Send your message to us

HRB400 High Tensile Rebars for Building Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords