HP 270 Non Woven Geotextile Fabric for Reinforcement and Drainage - CNBM China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Feature:

1. High tension.Because it's made of Plastic flat yarn,it can keep enough tenacity and stretching.

2. Non-corrosive.It can be non-corrosive for long time in soil and water with different PH value.

3. Good Water Permeability.There is space between flat yarn,so it has good water permeability.

4. Good antimicrobic. For organisms,there will be no worm-holes.

5. Easy construction.Because of light material,soft,it's easy for transportation,spreading out and construction.

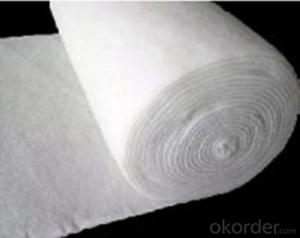

Staple fibers needle punched non woven geotextile

The geotextile is made of polypropylene staple fibers on cross-laying equipment and needle punched equipment.

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What are the specifications for geotextiles in subsurface drainage projects?

- The specifications for geotextiles in subsurface drainage projects typically include requirements for the material's strength, permeability, filtration properties, and durability. These specifications ensure that the geotextile can effectively separate soil particles from the drainage media, prevent clogging, and maintain its functionality over time. Additionally, the specifications may also address the geotextile's dimensions, weight, and installation guidelines to ensure proper performance in subsurface drainage applications.

- Q: What are geotextiles?

- Geotextiles are synthetic fabrics made from polypropylene or polyester that are used in civil engineering and construction to improve soil stability, drainage, and erosion control. They are permeable and provide strength and reinforcement to various applications such as roadways, retaining walls, and landfills.

- Q: How do geotextiles contribute to groundwater protection?

- Geotextiles contribute to groundwater protection by acting as a barrier that prevents the infiltration of contaminants into the groundwater. These specialized textiles are designed to allow water to pass through while retaining soil particles and other pollutants, thus filtering out harmful substances and protecting the quality of groundwater sources.

- Q: What is the high strength to strengthen the composite geotextile

- Bujia Weaving Bugatite Rope

- Q: Do you have a geotextile

- Summer to sunscreen, winter to antifreeze. The So summer not only to be able to block the sun, but also breathable. The Winter to warm good. The To achieve such a request, no matter what you can make the material. The

- Q: Can geotextiles be used in railway track bed stabilization?

- Yes, geotextiles can be used in railway track bed stabilization. Geotextiles are often used to prevent the mixing of different soil layers, increase the load-bearing capacity of the track bed, and improve drainage. They can also help in reducing settlement and improve overall stability of the track bed.

- Q: Can geotextiles be used in bridge abutment construction?

- Yes, geotextiles can be used in bridge abutment construction. Geotextiles can provide reinforcement, separation, and filtration functions in bridge abutments, helping to improve overall stability and prevent soil erosion.

- Q: What are the different geotextile durability test methods?

- There are several different geotextile durability test methods, including the accelerated aging test, the hydrolysis test, the ultraviolet (UV) exposure test, the chemical resistance test, and the abrasion resistance test. These tests are conducted to assess the long-term performance and durability of geotextiles in various environmental conditions.

- Q: How are geotextiles classified?

- Geotextiles are classified based on their manufacturing method, composition, and intended application.

- Q: What are the materials used in geotextile production?

- The materials used in geotextile production can vary, but common materials include synthetic fibers such as polypropylene, polyester, and polyethylene. Natural fibers like jute and coir may also be used.

Send your message to us

HP 270 Non Woven Geotextile Fabric for Reinforcement and Drainage - CNBM China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords