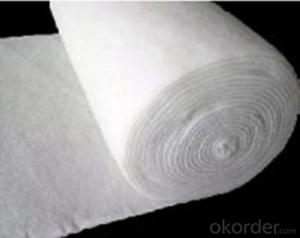

Gator Fabric Geotextile - Filament Non-Woven Geotextile for Reinforcement and Drainage from CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1) Weight / Mass: 100g/m2-800g/m2

2) Width: Within 6 m (1m-6m)

3) Length: 50m-100m/roll (as request)

4) Material: PP / PET

5) Color: Black , white , grey and other color

6) Certificate: CE/ISO9001 , ISO14001

7) Manufacturing method: nonwoven / woven

8) The Biggest geotextile manufacturer/factory in China for many years

Geotextile Type:Non-Woven Geotextiles

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What is the high strength to strengthen the composite geotextile

- The correct product name should be high-strength reinforced composite geotextile This is a different from the traditional geotextile new products. Reinforced geotextile is made of high-strength fiber tow and non-woven composite weaving, the process is arranged in parallel fiber bundles, give full play to the role of the yarn. Non-woven mat under which the warp technology will be wrapped around the bundle, so that fiber tow and non-woven together, not only to keep the non-woven filter, but also has the strength of woven cloth. Mainly used in: rivers and lakes, drains, reservoir dam control project and power plant ash dam, mine, airport, cargo yard, railway, highway, tunnel, municipal, environmental protection and other projects, with reinforcement, isolation, Drainage, protection and other functions, is an excellent geotechnical materials; the main role is to seepage and isolation of the grassroots level, to prevent soil erosion, sand, and the embankment foundation of the embankment increased tolerance. The superiority is mainly manifested in the following aspects: high strength composite reinforced geotextile anti-aging durability, the service life can reach and more than 100 years; high strength composite geotextile puncture high strength, physical indicators far more conventional geosynthetics Material strength index; high strength composite geotextile friction coefficient, the adhesion is particularly strong, increasing the adhesion of the isolation layer, taking into account the external factors on the impact of reinforced filter layer reduced; high-strength composite geotextile reinforced acid, alkali , Salt corrosion, in the low temperature and high temperature and UV anti-aging experiments, the physical indicators stable.

- Q: Can geotextiles be used for slope stabilization?

- Yes, geotextiles can be used for slope stabilization. Geotextiles are commonly used in slope stabilization projects to reinforce the soil, control erosion, and provide structural support. They can help improve the stability and strength of slopes by preventing soil movement, promoting vegetation growth, and distributing loads evenly.

- Q: Sng400-2.5gb / t-1998 geotextile is what the specifications

- SNG400-2.5 refers to the national standard polyester staple acupuncture non-woven geotextile 400g / ㎡, width 2.5m. The standard code for the GB / T-1998 staple fiber nonwoven geotextile is generally the SNG / (1) (2) / (3) - (4) / (5). (1) that the use of raw materials fiber code: PET-polyester, PP-polypropylene, PA-nylon, PV-vinylon, PE-Ethylene (conventional polyester are generally vacant omitted code) (2) that polyester staple fiber non-woven Geotextile per unit area weight. (3) that the composite products in the polyester staple fiber non-woven geotextile weight per unit area, non-composite product vacancies. (4) width, expressed in meters (5) production department number: can express the product more specific characteristics, functions, varieties, sequences, etc., the general vacancy. For example, 2.5m wide 400g / ㎡ polyester staple fiber non-woven geotextile representation of the method can be SNG / PET400-2.5, can also be expressed as SNG400-2.5

- Q: What are the different types of geotextile installation equipment?

- Some common types of geotextile installation equipment include geotextile rollers, geotextile stitchers, geotextile spreaders, geotextile staplers, and geotextile tensioners. These tools are used to efficiently and effectively install geotextiles in various applications such as erosion control, soil stabilization, and drainage systems.

- Q: Can geotextiles be used in the protection of retaining walls?

- Yes, geotextiles can be used in the protection of retaining walls. Geotextiles are commonly used as a barrier against soil erosion and to reinforce the soil behind retaining walls. They help to prevent the loss of backfill material and provide stability and strength to the structure.

- Q: What are the advantages of using geotextiles in mining operations?

- There are several advantages of using geotextiles in mining operations. Firstly, geotextiles act as a barrier, preventing the erosion of soil and rock particles, thereby reducing the potential for soil contamination and water pollution. Secondly, geotextiles can strengthen and stabilize the ground, providing increased support for heavy machinery and equipment used in mining operations. Additionally, geotextiles can be used to separate different layers of soil and rock, allowing for efficient drainage and filtration of water, which is crucial for maintaining the integrity of mining sites. Overall, the use of geotextiles in mining operations enhances environmental protection, improves operational efficiency, and ensures the safety of workers and surrounding ecosystems.

- Q: What are the different factors affecting the durability of geotextiles?

- There are several factors that can affect the durability of geotextiles, including exposure to UV radiation, chemical degradation, physical abrasion, moisture content, and temperature variations. Additionally, the quality and composition of the geotextile material, as well as proper installation and maintenance, can also impact its longevity.

- Q: What are the common problems encountered during geotextile installation?

- Some common problems encountered during geotextile installation include improper placement or alignment, inadequate tensioning or anchoring, damage to the geotextile during installation, inadequate overlap or seam strength, and difficulties in handling or maneuvering the geotextile due to its size or weight.

- Q: What are the advantages of using geotextiles over traditional construction materials?

- There are several advantages of using geotextiles over traditional construction materials. Firstly, geotextiles are lightweight and flexible, making them easier to handle and install compared to heavy materials like concrete or steel. Secondly, geotextiles have a high strength-to-weight ratio, providing excellent reinforcement and stabilization capabilities for soil and other materials. Additionally, geotextiles are permeable, allowing for proper drainage and preventing water buildup, which can lead to erosion or structural damage. Moreover, geotextiles are resistant to biological degradation, chemicals, and UV radiation, ensuring their long-term durability. Lastly, geotextiles are cost-effective, as they require less labor and equipment for installation and maintenance compared to traditional materials. Overall, the use of geotextiles offers numerous benefits in terms of efficiency, functionality, and sustainability in construction projects.

- Q: What are the applications of geotextiles?

- Geotextiles have a wide range of applications in civil engineering and environmental projects. They are commonly used in road construction, where they provide stability, erosion control, and reinforcement. Geotextiles are also utilized in landfills to separate and protect soil layers, preventing contamination. Additionally, they are employed in coastal engineering to mitigate erosion and stabilize shorelines. Geotextiles are also used in drainage systems, agriculture, and landscaping to control erosion, filter water, and promote vegetation growth.

Send your message to us

Gator Fabric Geotextile - Filament Non-Woven Geotextile for Reinforcement and Drainage from CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords