Terram 1000 PP Nonwoven Geotextile Fabric Reinforcement and Drainage CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

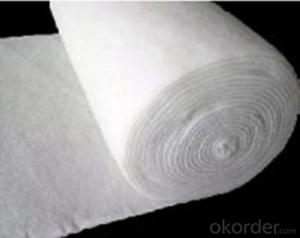

1. short fiber needle punched nonwoven geotextiles (heat set or not) Pet short fiber

Geotextiles are permeable nonwoven fabrics used to separate,filter,reinforce, protect or drain.Geotextiles allow filtration or separation of granular layers in roads and rail applications,used to protect membranes in landfill applications,used in coastal defence applications and used in landscaping to protect surfaces and structures from weeds and root growth.

Geotextiles are availabel as woven and non-woven .As liner protection, against physical damage, the non wovens are normally the answer.They are made up of fibers of polyester or polypropylene in random directions and punched together by needles during the manufacturing process.Geotextiles are commenly used to separate layers like clay and drainage and to protect liner from damage.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

- Q: Are geotextiles commonly used in civil engineering projects?

- Yes, geotextiles are commonly used in civil engineering projects. They are versatile materials that provide various functions such as soil stabilization, erosion control, filtration, and drainage. Geotextiles are used in a wide range of civil engineering applications including road construction, slope stabilization, landfill liners, and coastal protection. Their ability to enhance the performance and longevity of infrastructure makes them a popular choice in civil engineering projects.

- Q: What are the factors affecting the selection of geotextiles?

- The factors affecting the selection of geotextiles include the type and severity of the application, desired performance characteristics such as strength and filtration properties, site conditions such as soil type and slope stability, environmental considerations such as chemical resistance and durability, and cost-effectiveness.

- Q: Geotextile above allowed to plant grass?

- Geotextile above the grass To protect the slope, then the direct use of three-dimensional vegetation network can not Well! User name is the manufacturer phone! The The

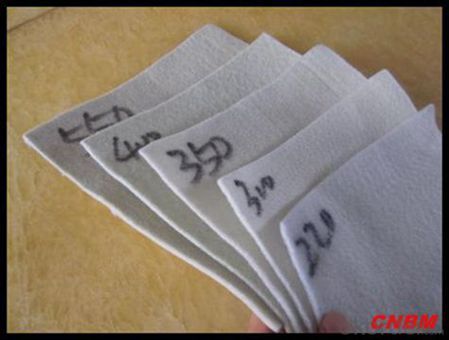

- Q: 200g 300g 400g non-woven geotextile price

- 200 grams of non-woven geotextile Price: 1.40 yuan. 300 grams of non-woven geotextile Price: 2.10 yuan. 400 grams of non-woven geotextile price of 2.80 yuan.

- Q: Contracted geotextile impermeable membrane laying artificial one square how much money

- Big bag of 4 yuan / square, I am specializing in the production of geotechnical materials

- Q: Can geotextiles be used in erosion control in stormwater detention ponds?

- Yes, geotextiles can be used in erosion control in stormwater detention ponds. Geotextiles are commonly used to stabilize and reinforce soil, prevent erosion, and filter water in various construction and environmental applications, including stormwater management. By placing geotextiles on the slopes and bottoms of stormwater detention ponds, they can help prevent soil erosion caused by the flow of stormwater, reduce sedimentation, and improve the overall effectiveness of the pond in controlling and managing stormwater runoff.

- Q: What are the limitations of using geotextiles in high-water flow conditions?

- One limitation of using geotextiles in high-water flow conditions is their potential to clog or become blocked with sediment or other debris. This can reduce their effectiveness in filtering water or preventing erosion. Additionally, geotextiles may not be able to withstand the extreme forces exerted by fast-moving water, leading to their failure or displacement. Therefore, it is crucial to carefully consider the flow conditions and choose appropriate geotextiles with sufficient strength and porosity for the specific application.

- Q: What are the physical properties of geotextiles?

- Geotextiles are synthetic materials that possess various physical properties. These properties include high tensile strength, which allows them to withstand heavy loads, excellent flexibility, which enables them to conform to uneven surfaces, and resistance to biological degradation, ensuring their long-term durability. Geotextiles also exhibit good permeability, allowing water to pass through while retaining soil particles, and have high resistance to UV radiation, enabling them to withstand exposure to sunlight. Additionally, they are lightweight, easily transportable, and easy to handle and install, making them a popular choice in various civil engineering and construction applications.

- Q: Can geotextiles be used in reservoir lining projects?

- Yes, geotextiles can be used in reservoir lining projects. Geotextiles are commonly employed to improve the stability and performance of reservoir linings by providing reinforcement, filtration, and separation functions. They can effectively prevent soil erosion, control seepage, and enhance the overall integrity and longevity of the reservoir lining system.

Send your message to us

Terram 1000 PP Nonwoven Geotextile Fabric Reinforcement and Drainage CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords