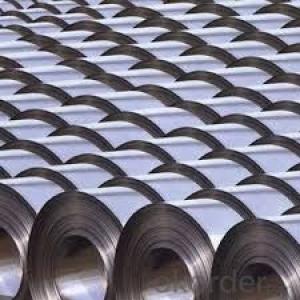

Hot Steel Rolled/jis g3141 spcc steel coil SPCC SPCD SPCE

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

JIS g3141 spcc cold rolled steel coil

Grade :SPCC,SPCD,SPCE

Width:600-1500mm

WT:0.15-3mm

Product Feature

Packaging Details: Wrapped by water prove paper and plastic film, covered by steel sheet, strapped with steel strips to prevent damage from transportation

Product Specification / Models

Standard: AISI, ASTM, DIN, GB, JIS

Grade: Q195, SPCC, SPCD, SPCE, DC01-0S, St12, ST14, ST15, ST16

Thickness: 0.2mm-2.0mm

Place of Origin: Tianjin, China (Mainland)

rand Name: TianJin MuChang

Model Number: 0.2-2.0mm*600-1500mm

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: oiled

Application: Construction,mechine,building,container manufacture,shipping building,

Special Use: High-strength Steel Plate

Width: 1000mm,1200mm,1219mm,1250mm,1500mm or as per customer's request

Length: Coil or as customs' request

Carbon constructional steel: SPCC,St12,DC01,Q235A/B/C/D Constructional quality steel: 20-45#,08-15#

Carbon quality steel coil: 08AL,Z,S,P SPCD,ST14

Low carbon deep-drawing coil: SC1,SPCE,SPCEN,ST14,DCO4 Extra-deep drawing coil: SC2,ST15,DCO5,SC3,ST16,DCO6,ST17 Corrosion-resistant steel: 05CuPCrNi,09CuPCrNi,Q345GNHL

Low carbon drawing steel: SPCD,ST13,DC03

Steel Coil: COLD ROLLED

Certificate: ISO, SGS, BV

Application

1.common structural parts and parts for drawing in engineering machines

2. transportation machine construction machines, lifting machine,

3. agricultural machines, light and civil industrial, household appliance industries.

4. chemical equipments, drive casing pipe and light industrial civil industries.

Other Information

Name Cold Rolled Steel Sheet Coil

GB11253-89,Q195 Q235,IS G3141,SPCC SGCC SPCD SPCE,DIN1623,ST12 ST13 SPCD ST14, EN10130,DC01 DC02,DC03

Thickness 0.18-3.0mm

Width 680mm-2000mm or 1000/1200/1219mm/1250mm

Finish General, bright, dull and mirror finish, oiled or non-oiled

Coil ID 508mm

Coil weight 5-12 tons.

Packing as client's requirement

Certificate ISO9001:2008

Standard GB11253-89, JIS G3141,DIN1623,EN10130

- Q: What are the factors affecting the strength of steel coils?

- There are several factors that can affect the strength of steel coils. 1. Steel Grade: The type and quality of the steel used in the coils plays a significant role in determining their strength. Different steel grades have varying levels of carbon content, alloying elements, and heat treatment processes, which can impact the overall strength and durability of the coils. 2. Manufacturing Process: The way in which the steel coils are manufactured can also affect their strength. Factors such as the temperature and duration of the heat treatment, the rolling and annealing processes, and the level of cold working can all influence the final strength of the coils. 3. Thickness and Width: The thickness and width of the steel coils can affect their strength. Thicker coils tend to be stronger and more resistant to deformation, while wider coils may exhibit variations in strength across their surface. 4. Surface Quality: The condition of the coil's surface, including any imperfections or defects, can influence its strength. Surface defects such as scratches, pits, or corrosion can act as stress concentration points, reducing the overall strength of the coil. 5. Storage and Handling: The way in which the coils are stored and handled can impact their strength. Factors such as exposure to moisture, extreme temperatures, or improper stacking and transportation can lead to deformation or damage, decreasing the strength of the coils. 6. Environmental Conditions: Environmental factors such as humidity, temperature, and exposure to corrosive agents can also affect the strength of steel coils. In harsh environments, the coils may experience accelerated corrosion, leading to a decrease in their strength over time. It is important to consider these factors when selecting and utilizing steel coils to ensure that they meet the required strength specifications for the intended application.

- Q: What is the cost of a steel coil?

- The cost of a steel coil can vary depending on various factors such as the size, thickness, grade, and market conditions. It is best to contact a supplier or check current market prices for an accurate cost.

- Q: I was cutting a sheet of steel with an angle grinder when suddenly the rate at which the blade was cutting slowed way down. I tried a few different things, and turned off the tool and looked at the blade. It didn't look damaged, but it definitely was not cutting as quickly. I thought either I had hit a harder section of steel (is that possible? It looked pretty uniform) or the blade had lost it's abrasive quality or something. Also, before this happened I had accidentally cut into the wooden sawhorse that was holding up the steel sheet, but I've done that before with no problem. After a short while the problem fixed itself and the rate of cutting went back to a fast normal. Anyone know why this happened?

- Sounds like the abrasive surface got blinded, coated with something that prevented the abrasive particles from touching the steel. It is possible to have vastly different hardnesses in a single piece of steel. Case hardening, carburizing, induction hardening, heat affected zone from welding, differences in work hardening, and presence of inclusions are some of the things that can create hardness variation within a single piece. But... sounds like you are working with a sheet which is unlikely to have any of these conditions. So... it was probably the grinding disk

- Q: Is steel with a black coloring as strong as regular steel. if you are asking why i have two wordsBlack Katana.I know a katana is not made with normal steel, it is made of two types with varying grades of carbon to give it speacial properties, i just want to know if the black will make a difference.

- The term tensile potential refers back to the quantity of tensile (stretching) rigidity a textile can stand up to in the previous breaking or failing. the in simple terms suitable tensile potential of a textile is calculated by making use of dividing the element of the textile examined (the pass area) by making use of the strain located on the textile, regularly expressed in terms of pounds or much consistent with sq. inch of fabric. Tensile potential is an considerable degree of a textile's skill to accomplish in an utility, and the scale is extensively used whilst describing the residences of metals and alloys.

- Q: This EN10025 S355JR is a European code for steel, of which the properties can be found here.

- Is bether to use this one below! ASTM A588/A588M. Standard Specification for High-Strength Low-Alloy Structural Steel with 50 ksi [345 MPa] Minimum Yield Point , Weather Resistant

- Q: What are the different certifications required for steel coil manufacturers?

- Steel coil manufacturers may be required to obtain various certifications in order to operate in the industry, ensuring that they meet specific quality and safety standards. One widely recognized certification is the ISO 9001, an international standard for quality management systems. This certification demonstrates the manufacturer's commitment to consistently meeting customer and regulatory requirements through the implementation of effective processes and procedures. Another crucial certification is the ISO 14001, which focuses on environmental management systems. By obtaining this certification, manufacturers prove their dedication to implementing sustainable practices and minimizing their environmental impact. In terms of safety, manufacturers may need certifications like the OHSAS 18001 or ISO 45001, which are standards for occupational health and safety management systems. These certifications guarantee that the manufacturer has established proper processes and controls to ensure the well-being of their employees and stakeholders. Additionally, manufacturers may require industry-specific certifications such as the American Institute of Steel Construction (AISC) certification, which is specific to structural steel fabrication and erection. This certification ensures that the manufacturer adheres to the best practices in the industry. Furthermore, manufacturers may need certifications related to specific product standards, such as the American Society for Testing and Materials (ASTM) certification. This certification guarantees that the manufacturer's products meet specific quality and performance requirements. Acquiring these certifications is crucial for steel coil manufacturers as they provide customers with confidence in the quality, environmental responsibility, and adherence to industry standards of their products.

- Q: How are steel coils used in the production of steel framing systems?

- Steel coils are used in the production of steel framing systems as they are unrolled and fed into a machine that shapes and cuts the steel into the desired lengths and profiles. These coils provide a continuous supply of high-quality steel, allowing for efficient and precise manufacturing of steel framing components, which are then assembled to create sturdy and durable steel structures.

- Q: How are steel coils protected from humidity?

- Steel coils are protected from humidity by applying a layer of corrosion-resistant coating, such as zinc or aluminum, to the surface of the coils. This coating acts as a barrier, preventing moisture from coming into direct contact with the steel and reducing the risk of corrosion. Additionally, the coils are often stored in a controlled environment with low humidity levels to further minimize the impact of moisture.

- Q: What are the different cutting methods for steel coils?

- There are several different cutting methods for steel coils, including shearing, slitting, and laser cutting. Shearing involves using a large blade to cut through the coil, typically resulting in a straight cut. Slitting involves passing the coil through circular blades that create narrower strips or sheets. Laser cutting uses a high-powered laser beam to melt or vaporize the steel, providing precise and intricate cuts. Each method has its advantages and is chosen based on the specific requirements of the project.

- Q: How are steel coils used in the production of solar panels?

- Steel coils are used in the production of solar panels as a crucial component for the frame and support structure. The coils are shaped and cut to size, providing the necessary strength and stability to hold the solar cells and other components securely in place.

Send your message to us

Hot Steel Rolled/jis g3141 spcc steel coil SPCC SPCD SPCE

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords