Hot selling pp non woven fabric (TNT) with good price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

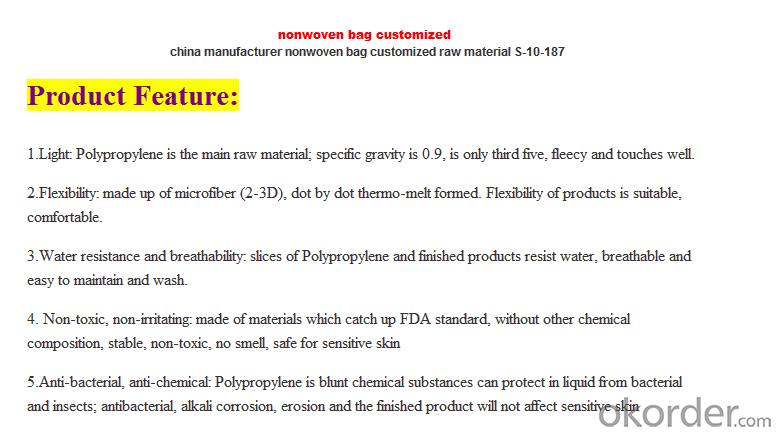

We are recognized as a reliable Manufacturer, Exporter and Supplier of Non Woven Fabric. We can provide Non Woven Fabric in any gram/m2 and any colour required by customer. Non Woven Fabrics are broadly defined as sheet or web structures bonded together by entangling fiber or filaments (and by perforating films) mechanically, thermally or chemically. PP Spun bonded Non woven Fabrics are produced using a precise extrusion-based technology. The polymer is stretched into a continuous filament and loosely spread onto a conveyor belt to form the web. Air is used to form and lay the fabric filaments. On the other hand, some non woven fabrics can be recycled after use, given the proper treatment and facilities.

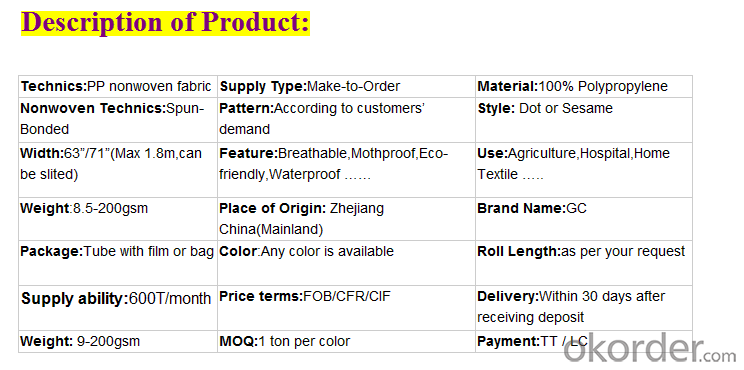

Product Specifications

Weight: 10 - 150 gsm

Width: Max 1600 mm (can be slit)

Fabric Roll Length: As per buyer’s need ( 200 - 1200 Mtr)

Color: various colors available.

Procedure of production: Spun bonded Non Woven, Diamond design

Material: polypropylene

Minimum Order: 1000 Kg

Sample: sample free, freight collect

Product Application

Non woven fabric manufacturers usually manufacture the fabric in a roll form. It is then sent to various other industries where it has end applications, where is it cut and given different form depending upon the use. They can also be used in combination with different materials and offer a wide range of products.

Colored Non woven fabrics are use in many sectors and variety of applications, such as Health, Hygiene, Medical, Packaging, Agriculture, Furniture Upholstery, Geo Textiles, Leather Industry, Shoes and Garments. Customers come from the textile and automotive industries as well as many other sectors.

- Q: What are the processes of dyeing and finishing of textiles?

- General process: fabric singeing - retreat bleaching pre-treatment - desizing - scouring - bleaching - mercerizing --- dyeing, printing - post-processing.

- Q: Textile fabric classification, dyeing and finishing processing is what?

- New type of fabric in the chenille fabric, knitted bamboo fabric should also be classified.

- Q: Textile machine, I should use single-phase power or three-phase electricity

- Single-phase electrical civilian electricity, if away from the transformer far, easy fluctuations in the electricity network, will cause voltage instability. Therefore, you should be based on your machine installed around the power situation to determine

- Q: Antistatic fabrics of textile electrostatic materials

- Resulting in the transfer of charge on the surface of the object, resulting in static electricity. With the same charge of the fibers are mutually exclusive, with different charges of fibers and mechanical parts between the attraction, resulting in sliver hair, yarn hairiness increased, bad package molding, fiber bonding parts, yarn breakage increased, As well as the formation of scattered cloth on the cloth and so on

- Q: What are the problems with the transformation and upgrading of the processing trade of textile enterprises?

- As we all know, since 2008 the development of the textile industry has been affected by many factors, there have been a series of new situations and new problems. In the first half, such as the appreciation of the renminbi, the export tax rebate rate down, tight monetary policy, labor, land, energy and other factors

- Q: Textile finishing TPU, TPEF film. What's the difference?

- High mechanical strength. TPU products carrying capacity, impact resistance and shock absorption performance. TPU

- Q: What is the textile technology profession now?

- Dyeing and finishing technology; this course more systematically describe the various textile fiber products in the dyeing and finishing of the basic process and process conditions, and the principles and commonly used machinery and equipment for a brief introduction, so that beginners master the basic knowledge of dyeing and finishing The

- Q: How to grow in the textile industry and have their own customers

- You count down, so that the total loss of 20%, only 800KG fabric, and if you do clothes, cut when the loss plus, it is very impressive

- Q: DTY FDY POY What are the textile raw materials?

- POY: pre-oriented wire, full name: PRE-ORIENTED YARN or PARTIALLY ORIENTED YARN. Refers to an incomplete stretch of synthetic filaments obtained between high-speed and non-oriented and drawn yarns obtained by high-speed spinning. Compared with the undrawn yarn, it has a certain degree of orientation, good stability, often used as tensile false twisted yarn (DTY) of the special wire. (Generally not used for weaving)

- Q: The meaning of the following terms in the textile industry: fabric, processing number, genuine number.

- If the same is the cotton fabric gauze than pure cotton shrinkage rate. Shrinkage of pure cotton <pure linen <silk. The ratio is about 5%: 8%: 12%.

Send your message to us

Hot selling pp non woven fabric (TNT) with good price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches