Top Quality Tear-Resistant Dot Style Recycled Non Woven Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

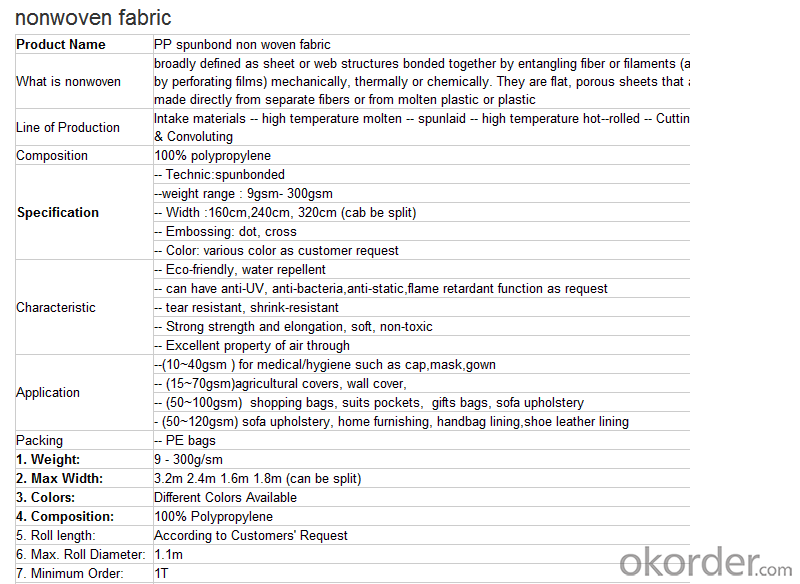

We are recognized as a reliable Manufacturer, Exporter and Supplier of Non Woven Fabric. We can provide Non Woven Fabric in any gram/m2 and any colour required by customer. Non Woven Fabrics are broadly defined as sheet or web structures bonded together by entangling fiber or filaments (and by perforating films) mechanically, thermally or chemically. PP Spun bonded Non woven Fabrics are produced using a precise extrusion-based technology. The polymer is stretched into a continuous filament and loosely spread onto a conveyor belt to form the web. Air is used to form and lay the fabric filaments. On the other hand, some non woven fabrics can be recycled after use, given the proper treatment and facilities.

Product Specifications

Weight: 10 - 150 gsm

Width: Max 1600 mm (can be slit)

Fabric Roll Length: As per buyer’s need ( 200 - 1200 Mtr)

Color: various colors available.

Procedure of production: Spun bonded Non Woven, Diamond design

Material: polypropylene

Minimum Order: 1000 Kg

Sample: sample free, freight collect

Product Application

Non woven fabric manufacturers usually manufacture the fabric in a roll form. It is then sent to various other industries where it has end applications, where is it cut and given different form depending upon the use. They can also be used in combination with different materials and offer a wide range of products.

Colored Non woven fabrics are use in many sectors and variety of applications, such as Health, Hygiene, Medical, Packaging, Agriculture, Furniture Upholstery, Geo Textiles, Leather Industry, Shoes and Garments. Customers come from the textile and automotive industries as well as many other sectors.

- Q: What kind of fiber can be used as textile fiber

- Fibers derived from plant bursa such as flax, jute, apricot and the like; fibers derived from plant leaves such as sisal, abaca and the like. The main chemical composition of plant fiber is cellulose, it is also known as cellulose fiber

- Q: What are the common textile auxiliaries?

- Reduce waste pollution, improve environmental quality. Improve the printing and dyeing effect and the appearance of the fabric and the inherent quality.

- Q: What are the processes of dyeing and finishing of textiles?

- Pre-treatment, dyeing, printing, post-processing and other processes. Worsted fabric - billet - singeing - Lian Bo - wash it - Lian Bo - drying - in the inspection - cooked - cut hair - pressure light - tank steaming.

- Q: Textile fabric classification, dyeing and finishing processing is what?

- New type of fabric in the chenille fabric, knitted bamboo fabric should also be classified.

- Q: Sponges are plastic or textiles

- Sponge: Polyurethane soft foam rubber, polyurethane is the most common in life a polymer material, widely used in the production of various "sponge" products

- Q: Are hats a class of textile and apparel products?

- Hats are popular for textile products, processing or general trade.

- Q: The difference between double distribution and processing in textile fabrics

- Processing - the fabric is your own to buy, you get inside the factory processing

- Q: What are the policy measures developed by the Bangladeshi government for their exports?

- As a rising star of the Asian textile industry, in recent years, Bangladesh textile products in the international textile market has a strong competitive edge

- Q: What is eco textile?

- Consumption ecology - from the perspective of human ecology, the study of the residual toxic substances in textiles on human health; 3. dealing with ecology - from the perspective of ecological treatment, control of textile recyclable, natural degradation, waste treatment Its release of toxic substances harmless to the environment.

- Q: What are the raw materials for textiles?

- Modern textile products range, widely used. People wear on the head, who wear, hands on the set, the feet are inseparable from the textiles.

Send your message to us

Top Quality Tear-Resistant Dot Style Recycled Non Woven Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords