short width and small roll pp spunbond non woven fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

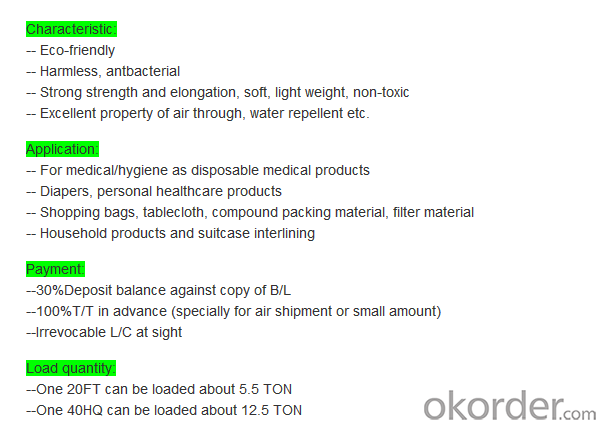

We are recognized as a reliable Manufacturer, Exporter and Supplier of Non Woven Fabric. We can provide Non Woven Fabric in any gram/m2 and any colour required by customer. Non Woven Fabrics are broadly defined as sheet or web structures bonded together by entangling fiber or filaments (and by perforating films) mechanically, thermally or chemically. PP Spun bonded Non woven Fabrics are produced using a precise extrusion-based technology. The polymer is stretched into a continuous filament and loosely spread onto a conveyor belt to form the web. Air is used to form and lay the fabric filaments. On the other hand, some non woven fabrics can be recycled after use, given the proper treatment and facilities.

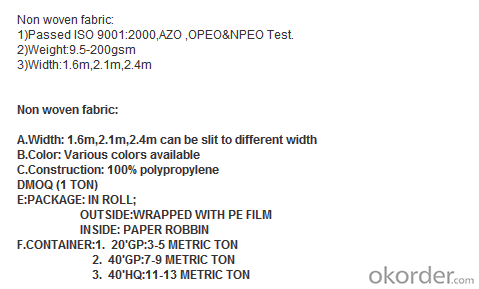

Product Specifications

Weight: 10 - 150 gsm

Width: Max 1600 mm (can be slit)

Fabric Roll Length: As per buyer’s need ( 200 - 1200 Mtr)

Color: various colors available.

Procedure of production: Spun bonded Non Woven, Diamond design

Material: polypropylene

Minimum Order: 1000 Kg

Sample: sample free, freight collect

Product Application

Non woven fabric manufacturers usually manufacture the fabric in a roll form. It is then sent to various other industries where it has end applications, where is it cut and given different form depending upon the use. They can also be used in combination with different materials and offer a wide range of products.

Colored Non woven fabrics are use in many sectors and variety of applications, such as Health, Hygiene, Medical, Packaging, Agriculture, Furniture Upholstery, Geo Textiles, Leather Industry, Shoes and Garments. Customers come from the textile and automotive industries as well as many other sectors.

- Q:The Factors Affecting the Capillary Effect of Textile Garment

- The higher the effect, the better the impact of post-processing quality, such as leveling, dyeing rate, fastness and so on.

- Q:What are the common textile auxiliaries?

- Textile dyeing and finishing auxiliaries in the textile processing technology has a very important role, although the amount is not large, but in the textile processing technology has a role can not be ignored, and sometimes even have an indispensable role, summed up, textile dyeing and finishing auxiliaries In the textile products in the main play a focus on the role

- Q:Cotton chemical fiber textile, hemp textile, wool textile, silk silk textile industry, the difference between the four

- From 2000 to this year, the national cotton acreage, yield and cotton market supply and demand relationship, the rapid development of China's cotton industry, from the cultivation of surface cross, production and enterprise scale have unprecedented unprecedented development, but also to the textile industry development into power, Promote China's textile industry into a new period of development, the international competitiveness increased significantly

- Q:What is the difference between the nonwovens industry and the textile industry?

- Nonwovens finished low, to replace the traditional textiles, of course, is able to replace the place

- Q:Development of Textile Fibers.

- From the domestic economic environment, domestic demand will become an important driving force for industry growth. At present, about 80% of Chinese textile consumption in the country. With the sustained and rapid growth of the domestic economy, the stability of residents' income will boost the further development of the domestic market.

- Q:Why is cotton textiles shrinking?

- At the same time, when the fabric is wetted, the water molecules enter the interior of the cotton fiber and the fibers are puffed, and the fabric shrinks when the weft (or warp) of the fabric becomes thicker. This is the cotton fabric soaked in water, there will be "shrink" the cause of the phenomenon.

- Q:What causes the loss of textile enterprises

- Roughly three points, each of the textile industry has its own characteristics, including the cost, including sales channels

- Q:How does the chemical composition of the textile be analyzed?

- PH value, formaldehyde content, lead content, azo dye test, heavy metal content test, water absorption, moisture content, odor, cotton mercerizing effect, hot pressing, dry heat, storage sublimation, acid spots, Spots, phenolic yellowing and so on.

- Q:What is a large circular machine and a small circular machine in the textile?

- Second, the large circular machine also has low-grade products, small round machine also has quality products. Brand knitting circular machine is in the high-end products, the size of the specifications are, and the name of the assembly of the knitting machine is also the size of the size of the specifications, but its performance, function and accuracy is far better than the brand machine.

- Q:tera textile processing where to learn

- Textile-related materials are available through collection. You can in the big city of the relevant office where the NPC get the drawings and then that textile

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

short width and small roll pp spunbond non woven fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords