Hot Rolled Steel I-Beam with best quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering high quality Hot Rolled Steel I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel I-Beams are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

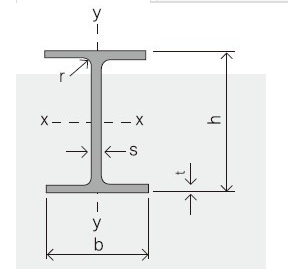

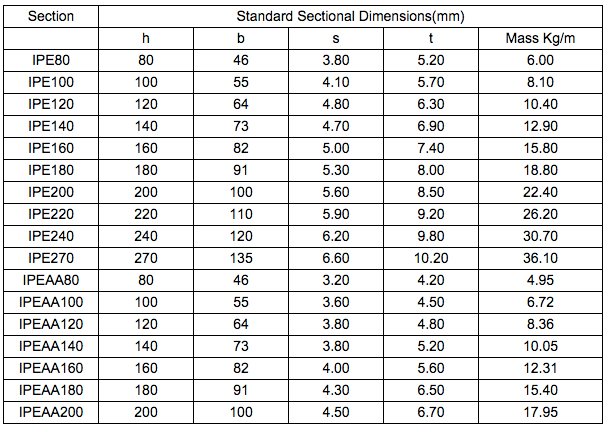

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What is the normal tolerance of your steel products ?

A3: Normally 7%-9%, but we can also produce the goods according to the customers' requests.

Images:

- Q: What are the different types of connections used with steel I-beams?

- There are several types of connections used with steel I-beams, including welded connections, bolted connections, and pinned connections. Welded connections involve joining the I-beams using a welding process, creating a strong and permanent connection. Bolted connections use bolts and nuts to secure the beams together, providing a sturdy and easily adjustable connection. Pinned connections involve using pins or bolts placed through holes in the beams, allowing for rotational movement at the connection point while still maintaining support.

- Q: What are the common testing methods used to verify the quality of steel I-beams?

- The common testing methods used to verify the quality of steel I-beams include visual inspection, dimensional analysis, mechanical testing such as tensile and yield strength tests, non-destructive testing methods like ultrasonic testing and magnetic particle inspection, and chemical composition analysis through spectroscopy.

- Q: How do steel I-beams perform in high humidity environments?

- Steel I-beams are generally known for their strength and durability, and they perform well in high humidity environments. However, prolonged exposure to high humidity can have some potential effects on steel I-beams. One of the primary concerns in high humidity environments is the possibility of corrosion. When steel is exposed to moisture, especially in the presence of oxygen, it can react and form rust, which weakens its structural integrity. In areas with consistently high humidity, the risk of corrosion may be higher. To mitigate the effects of humidity on steel I-beams, several measures can be taken. Firstly, the steel can be coated with protective coatings such as paint or galvanization. These coatings act as a barrier against moisture and help prevent corrosion. Regular inspection and maintenance are also essential to identify and address any signs of corrosion before they worsen. Additionally, proper ventilation and humidity control within the environment can help minimize the risk of moisture accumulation on the surface of steel I-beams. By maintaining relative humidity levels within recommended ranges, the likelihood of corrosion can be significantly reduced. Overall, while steel I-beams are generally reliable in high humidity environments, it is crucial to implement protective measures and maintenance practices to ensure their long-term performance and structural integrity.

- Q: Relationship between H steel and I-beam, C section steel and channel steel

- Difference: 1. Under the condition of the same amount of steel, H steel can do more rigidity and stability than I-beam, and its resistance to bending and bending is better than that of I-beam2, the shape of H steel on the lower flange far wider than I-beam3, the process of H steel can be rolled or welded, steel are rolled

- Q: How are steel I-beams installed during construction?

- Steel I-beams are typically installed during construction by first preparing the foundation or structural supports. The I-beams are then lifted into place using cranes or other heavy machinery. They are aligned and secured to the supports using bolts or welding. Additional components, such as columns or cross braces, may be added to enhance stability and structural integrity.

- Q: How do steel I-beams perform in terms of thermal expansion and contraction?

- Steel I-beams have a relatively low coefficient of thermal expansion, meaning they expand and contract less than other materials when exposed to temperature changes. This characteristic makes them highly stable and less prone to warping or structural damage due to thermal variations.

- Q: What are the maintenance requirements for steel I-beams?

- The maintenance requirements for steel I-beams typically involve regular inspections for signs of corrosion, damage, or structural issues. Cleaning the surface and applying protective coatings can help prevent rust and extend the lifespan of the beams. Additionally, it is important to address any issues promptly to avoid further damage and ensure the structural integrity of the beams.

- Q: What are the common types of connections for steel I-beams in moment frames?

- Steel I-beams in moment frames can be connected in various ways, including bolted, welded, and hybrid connections. Among the most commonly used connection types in moment frames are bolted connections. These connections involve securing the beams and columns together using bolts. To ensure a strong and rigid connection, the bolts are typically tightened to a specified torque. Another common type of connection for steel I-beams in moment frames is welded connections. In this type of connection, the beams and columns are joined together through a welding process, such as arc welding. Welded connections offer excellent strength and rigidity, but they require skilled welders to execute them correctly. Hybrid connections, on the other hand, combine both bolted and welded connections. This type of connection is often employed when different parts of the moment frame necessitate different connection methods. For instance, bolted connections may be utilized for the primary beam-to-column connections, while welded connections may be suitable for secondary bracing members. It should be emphasized that the choice of connection type in a steel moment frame depends on several factors, including design requirements, loading conditions, and the overall structural configuration. It is crucial to adhere to industry standards and guidelines when selecting the connection type to ensure the moment frame's safety and structural integrity.

- Q: Can steel I-beams be used for railway tracks?

- No, steel I-beams are not typically used for railway tracks. Instead, steel rails specifically designed for railways are used as they provide better stability, durability, and load-bearing capacity required for heavy train traffic.

- Q: What are the considerations for fireproofing when using steel I-beams in public buildings?

- When using steel I-beams in public buildings, fireproofing is a crucial consideration to ensure the safety of occupants and protect the structural integrity of the building. Here are some key considerations for fireproofing steel I-beams: 1. Building codes and regulations: Compliance with local building codes and regulations is essential. These codes typically specify the fire resistance requirements for structural elements, including steel beams. They outline the necessary fire ratings, which indicate the duration that the steel beams should withstand fire without compromising their structural integrity. 2. Fire protection materials: There are various fire protection materials available for steel I-beams, including intumescent coatings, gypsum-based sprays, and cementitious sprays. These materials provide a barrier between the steel and the fire, delaying the heat transfer and preventing the beams from reaching critical temperatures. The choice of fire protection material should be based on factors such as fire rating requirements, aesthetics, application method, and cost. 3. Thickness and coverage: The thickness and coverage of the fire protection material are crucial to achieving the desired fire rating. The manufacturer's guidelines should be followed to ensure the correct thickness is applied uniformly to all surfaces of the steel I-beams. Any gaps or areas left unprotected can compromise the fire resistance performance. 4. Adherence and durability: The fireproofing material should have excellent adherence to the steel surface to ensure it remains in place during a fire event. Additionally, it should exhibit durability to withstand factors like moisture, vibrations, and general wear and tear to maintain its fire protection properties over time. 5. Access and maintenance: Proper access should be provided to inspect and maintain the fireproofing system. Regular inspections should be carried out to identify any damage, degradation, or areas where the fireproofing might have been compromised. Maintenance activities like repairs or reapplication of the fireproofing material should be conducted as necessary to ensure the continued fire resistance of the steel I-beams. 6. Collaboration with experts: It is advisable to involve fire protection engineers, architects, and other experts in the design and construction process. These professionals can provide guidance on fireproofing requirements, material selection, and installation techniques to ensure optimal fire safety. Considering these factors for fireproofing steel I-beams in public buildings will help create a safe environment for occupants, prevent structural failure during a fire, and comply with building codes and regulations.

Send your message to us

Hot Rolled Steel I-Beam with best quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords