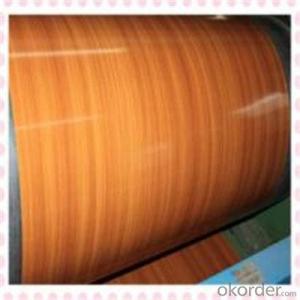

hot rolled PPGI printed steel coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of prepainted galvanized steel coil

Base Material | (1)Galvanized steel; |

Grade | SGCC, DX5ID, ASTM, EN10142, S350GD, etc |

Thickness | 0.18~1.00mm |

Width | ≤1250mm |

Zinc Coating | 50~200g/m2 |

Pattern | Wood grain, Marble, Brick, granite and Camouflage series, etc |

Paint | PE , PVDF , SMP , HDP |

Coil ID | ø508mm |

Coil Weight | ≤6T |

Application of wooden prepainted galvanized steel coil

Widely used in construction, household appliance, furniture, transportation and other industry

Width | 600mm-1250mm |

Color | Grey white, sea blue, red or any RAL standard |

Standard | ASTM, AISI, DIN, GB,JIS |

Material | SGCC,SGCD,SECC,SECD,DX51D+Z, S350GD, S450GD, S550GD |

Technique | Cold rolled, hot-dipped galvanizing, color coated, galvanized, Galvalume |

Surface Structure | Galvanized, Galvalume, zero spangle, regular spangle or normal spangle |

Surface treatment | Chromate and oiled, chromate and non-oiled |

Min order | 25 tons |

Applications:

Construction | Outside | Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth |

Inside | Door, doorframe, light steel roof structure, folding screen, elevator, stairway, vent gutter | |

Electrical appliance | Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker | |

Furniture | Central heating slice, lampshade, desk, bed, locker, bookshelf | |

Carrying trade | Exterior decoration of auto and train, clapboard, container, isolation board | |

Others | Writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment | |

- Q: What products can we make with steel (eg Steel strip, rod, bar, rail, tube) How are these made? What can we make from these steel products?Can you please make the answers as detailed as possible you can because i really want to know this really well. Thank you.

- Your okorder (they make steel deck and steel joists) There are thousands of other items routinely produced from steel, including rebar, and all the metal in cars, airplanes, and about a million other things.

- Q: What are the common methods of storing steel coils in warehouses?

- Warehouses employ various methods to store steel coils, taking into account factors such as coil size and weight, available space, and resources. Here are some commonly utilized techniques: 1. Block stacking: Coils are stacked directly on top of one another in a block formation. Typically, they are arranged in rows and columns, with wooden or rubber blocks inserted between layers to maintain stability and prevent damage. 2. Racking systems: Racks are frequently employed to store steel coils efficiently. These systems encompass different types of racks, such as cantilever racks, coil racks, and structural racks. They provide an organized framework for storing and accessing coils, maximizing space utilization. 3. Coil cradles: Designed specifically for steel coils, coil cradles consist of multiple cradles or saddles that securely hold the coils in place. By stacking these cradles, warehouses can optimize vertical space usage. 4. Coil pads: Coil pads are flat platforms made of materials like wood, rubber, or foam. They are placed on the warehouse floor, serving as a base for directly stacking steel coils. Coil pads distribute the weight evenly while protecting the coils from floor contact damage. 5. Slit coil storage: Specialized storage systems are employed for storing narrower and lighter slit coils. These systems often include racks or shelves equipped with dividers or separators to maintain coil organization and prevent unraveling. It is crucial to observe safety precautions when handling and storing steel coils in warehouses, regardless of the storage method. This entails ensuring proper weight distribution, utilizing appropriate lifting equipment, and adhering to industry-specific guidelines and regulations.

- Q: How are steel coils labeled for identification?

- Steel coils are typically labeled for identification using a combination of unique alphanumeric codes, barcodes, or labels that include important information such as the coil's dimensions, weight, grade, production date, and supplier details.

- Q: How are steel coils used in the production of steel clips?

- Steel coils are used in the production of steel clips by being unwound and fed into a machine, where they are cut, shaped, and formed into the desired clip design.

- Q: How are steel coils used in the manufacturing of steering columns?

- Steel coils are used in the manufacturing of steering columns as they provide strength and durability to the structure. The steel coils are typically formed into a cylindrical shape and then welded or joined together to create the main body of the steering column. This ensures that the steering column can withstand the forces and impacts experienced during vehicle operation, providing stability and control to the driver.

- Q: Can steel coils be coated with heat-resistant materials?

- Yes, steel coils can be coated with heat-resistant materials.

- Q: How do you prevent damage to steel coils during transportation?

- To prevent damage during the transportation of steel coils, there are several measures that can be taken: 1. Tight and secure packaging: It is important to pack the steel coils tightly and securely to prevent any movement or shifting during transportation. This can be achieved by using appropriate packaging materials such as steel cradles, wooden dunnage, or steel straps to hold the coils in place. 2. Use cushioning materials: Adding cushioning materials like foam padding, cardboard, or bubble wrap between the coils can help absorb shocks and vibrations during transit. This additional layer of protection minimizes the risk of scratches, dents, or other damages caused by contact with other objects or surfaces. 3. Handle and load properly: It is crucial to use proper lifting equipment and techniques to avoid mishandling and dropping of the steel coils. Carefully lifting and loading the coils onto transportation vehicles using forklifts or cranes is recommended. Additionally, stacking the coils in a way that distributes weight evenly helps maintain stability. 4. Protect from weather: Steel coils are susceptible to corrosion, so it is essential to shield them from moisture and adverse weather conditions during transportation. Covering the coils with waterproof and weather-resistant tarps or shrink wrap prevents water or moisture from reaching the steel surfaces. 5. Regular inspections: Conducting regular inspections before, during, and after transportation is vital to identify any potential damage or issues. This allows for timely intervention to rectify any problems and prevent further damage. 6. Trained personnel: It is crucial to ensure that personnel involved in handling, loading, and transporting the steel coils are properly trained. They should be knowledgeable about the correct procedures and techniques to safely handle and transport the coils, reducing the risk of damage. By implementing these preventive measures, the likelihood of damage to steel coils during transportation can be significantly reduced, ensuring that the coils reach their destination in optimal condition.

- Q: How are steel coils inspected for coil set using deflection measurement?

- Steel coils are commonly inspected for coil set, a condition where the coil exhibits a curvature along its length, by utilizing deflection measurement techniques. Deflection measurement involves applying a force on the coil and measuring the resulting deviation from its original shape. To inspect for coil set, the steel coil is placed on a testing apparatus that can apply controlled pressure to the coil. This apparatus typically consists of a set of rollers or hydraulic cylinders that can exert force on the coil's surface. The first step in the inspection process is to secure the coil in place, ensuring it is properly aligned and centered on the testing apparatus. Once the coil is in position, the apparatus applies a known force along the length of the coil. This force is typically applied in a consistent and controlled manner to ensure accurate measurements. As the force is applied, the deflection of the coil is measured using sensors or gauges positioned at specific points along the length of the coil. These sensors can detect even small deviations from the original shape of the coil. The deflection measurements are recorded and analyzed to determine the severity of coil set. Typically, a set of predetermined acceptance criteria is used to assess the coil's condition. If the recorded deflection measurements exceed these criteria, it indicates the presence of coil set. The severity of the coil set can be determined by comparing the actual deflection measurements with the acceptable range specified by the criteria. Deflection measurement is an effective method for inspecting steel coils for coil set as it provides quantitative data on the deviation from the original shape. This information allows manufacturers to identify and address any coil set issues, ensuring the quality of the steel coils before further processing or shipment to customers.

- Q: What are the different types of steel coil storage containers?

- There are several types of steel coil storage containers, including coil racks, coil cradles, coil saddles, and coil cars.

- Q: I know that carbon steels and alloy steels are different but are carbon steels still alloys?Thanks!

- Carbon steel, or plain-carbon steel, is a metal alloy. It is a combination of two elements, iron and carbon. Depending upon the amount of presence of carbon in the alloy, Carbon steel can be classified into 4 different categories- Low Carbon Steel Medium Carbon Steel High Carbon Steel Very High Carbon Steel

Send your message to us

hot rolled PPGI printed steel coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords