Hot Rolled Plate Steel Cheap Price 2016 New Desigh

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

DESCRIPTION:

GRADE: SS400, ASTM A36, A572, ST37,ST52, Q195, Q215, Q235,Q345, S235JR etc.

STANDARD: GB/T709-2006, ASTM A36, JIS G3101, DIN EN 10025, SAE 1045, ASTM A570

SPEC: 1)Width: 600-2500mm or 1000,1050,1250,1500,1800,2000mm

2)Thickness:1.5mm-200mm or as customers’ special requirements;

3)Length: 2-12m or as customers’ special requirements

PACKING:

1.Big thickness:by bulk vessel

2.Small thickness:packed by steel strips and shipped by container

3.According to the requirements of customers'

TRADE TERMS :FOB, CFR, CIF

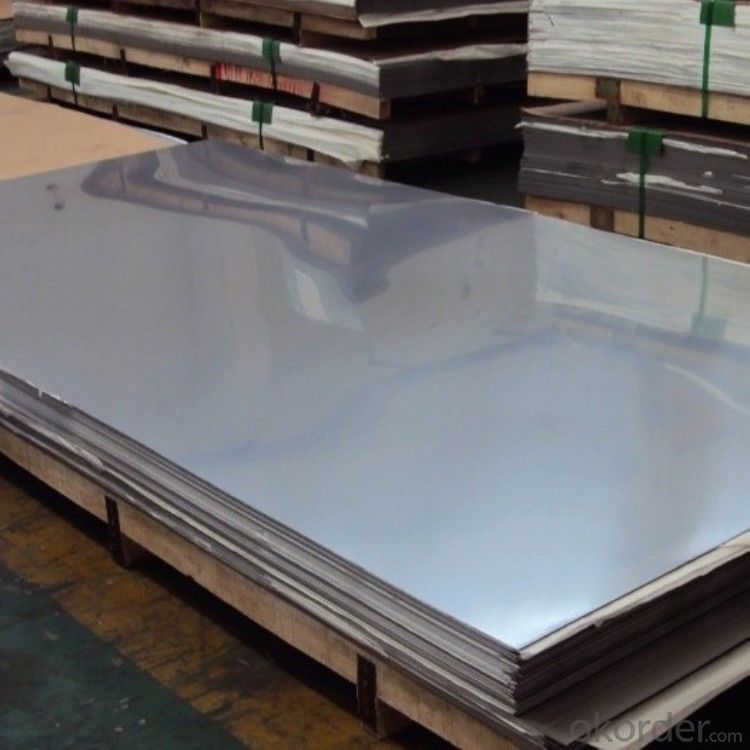

DETAILED PICTURES FOR STEEL COILS

FAQ:

Q:Do you have OEM service?

A: Yes.Variety of products size,quality and quantity can be customized according to your need.

Q:Could you support free sample?

A:Yes.We can supply FREE samples.But the delivery charges will be covered by our customers.

Q:How about the delivery time?

A:Within 15-30days after receiving the deposit or L/C at sight.

- Q: Can steel sheets be used for manufacturing shipping pallets?

- Certainly, the utilization of steel sheets is applicable in the production of shipping pallets. Steel, a material known for its strength and durability, is capable of enduring heavy loads, rendering it suitable for pallet construction. To establish a robust and dependable pallet structure, steel sheets can be united through welding or bolting. Furthermore, steel pallets possess the added advantage of being resistant to moisture, pests, and fire, which holds significance in certain industries or applications. Nevertheless, it is important to acknowledge that steel pallets generally incur higher costs compared to alternative materials like wood or plastic. Therefore, the decision to employ steel sheets for manufacturing shipping pallets would rely on specific requirements, budgetary constraints, and intended utilization.

- Q: What are the standard tolerances for steel sheets?

- The standard tolerances for steel sheets can vary depending on the specific grade, thickness, and dimensions of the sheet. However, common industry tolerances for steel sheets typically range from +/- 0.010 to +/- 0.125 inches for thickness, and +/- 0.005 to +/- 0.25 inches for width and length dimensions.

- Q: What is the typical coefficient of thermal expansion of a steel sheet?

- Steel sheets typically have a coefficient of thermal expansion of approximately 10-12 ppm/°C. This signifies that for every degree Celsius rise in temperature, the steel sheet will expand uniformly in all directions by 10-12 ppm. However, it is crucial to acknowledge that the coefficient of thermal expansion may differ based on the precise type and composition of the steel. Various steel alloys may exhibit slightly varied coefficients, although the range of 10-12 ppm/°C is widely accepted as the average.

- Q: What is the maximum load-bearing capacity of steel sheets?

- The specific type and thickness of steel sheets can cause the maximum load-bearing capacity to vary. Steel sheets are generally known for their strength and durability, which allows them to handle heavy loads. The load-bearing capacity of steel sheets is typically measured by its yield strength or ultimate tensile strength. Yield strength refers to the maximum stress a steel sheet can handle before permanently deforming, while ultimate tensile strength refers to the maximum stress it can handle before fracturing. The load-bearing capacity of steel sheets can range from a few hundred pounds to several thousand pounds per square inch (psi). For instance, mild steel sheets usually have a yield strength of approximately 50,000 psi, enabling them to support moderate loads. Conversely, high-strength steel sheets can have a yield strength of over 100,000 psi, allowing them to withstand heavy loads. It's important to consider that the load-bearing capacity of steel sheets can also be affected by factors such as dimensions, surface condition, and support method. Moreover, engineers and structural designers often take safety margins and the factor of safety into account when determining the maximum load-bearing capacity of steel sheets for specific applications. Therefore, it is advisable to consult relevant engineering standards, specifications, or professionals for accurate load-bearing capacity information in a particular context.

- Q: What is the difference between a perforated and non-perforated steel sheet?

- The main difference between a perforated and non-perforated steel sheet lies in their respective designs and functionalities. A perforated steel sheet is characterized by having small holes or perforations evenly distributed throughout its surface. These holes can be of different shapes and sizes, depending on the specific application requirements. The primary purpose of a perforated steel sheet is to allow for the passage of air, light, sound, and liquids through the sheet, while still maintaining its structural integrity. This makes it highly suitable for applications where ventilation, filtration, or visibility is essential. Perforated steel sheets are commonly used in industries such as architecture, automotive, manufacturing, and construction, where they are employed for various purposes, including acoustic panels, protective barriers, decorative elements, and filter screens. On the other hand, a non-perforated steel sheet does not have any holes or perforations on its surface. It is a solid sheet of steel that is typically used for applications where strength, durability, and resistance to impact or abrasion are important factors. Non-perforated steel sheets are often utilized in structural engineering, machinery, shipbuilding, and heavy-duty equipment manufacturing, as they provide a solid and reliable surface for load-bearing and other demanding applications. In summary, the difference between a perforated and non-perforated steel sheet lies in their design and functionality. Perforated steel sheets have small holes throughout their surface, allowing for the passage of air, light, sound, and liquids, while non-perforated steel sheets are solid sheets without any holes, providing strength and durability for heavy-duty applications.

- Q: What is galvanized steel sheet?

- Galvanized steel sheet is a steel type that has been given a protective layer of zinc to prevent corrosion. To achieve this, the steel sheet is immersed in molten zinc, resulting in a strong bond between the zinc and the steel surface. As a result, a long-lasting and resilient material is formed, which is highly resistant to rust and other forms of corrosion. The zinc coating acts as a sacrificial barrier, meaning that it will corrode before the steel beneath it. This property makes galvanized steel sheet an ideal option for outdoor applications or environments with high humidity or exposure to moisture. It is widely used in industries such as construction, automotive manufacturing, and household appliance production. Galvanized steel sheets have a distinct silver-gray appearance due to the presence of the zinc coating. They offer exceptional strength and durability, making them suitable for a variety of structural uses. Moreover, galvanized steel sheets require minimal maintenance and upkeep to preserve their corrosion resistance. To summarize, galvanized steel sheet is a steel type that has been coated with zinc to protect it from corrosion. This coating provides exceptional durability and resistance to rust, making it a popular choice in various industries.

- Q: Can steel sheets be painted after installation?

- After the installation, it is possible to paint steel sheets for aesthetic improvement and protection against rust and corrosion. However, before applying paint, it is crucial to ensure that the surface is clean and devoid of any pollutants. Adequate preparation, such as cleaning and sanding, is necessary to promote adhesion and achieve a durable finish. It is advisable to use a primer specifically formulated for steel surfaces before applying the desired paint color. Moreover, selecting a high-quality paint suitable for exterior or industrial use will yield optimal results and longevity.

- Q: Can 16Mn steel plate be used instead of Q345D steel plate?

- 16Mn steel plate, equivalent to Q345A steel plate, can not be replaced.

- Q: Can steel sheets be customized in terms of thickness?

- Yes, steel sheets can be customized in terms of thickness. Steel sheets are manufactured in various thicknesses to cater to different applications and requirements. The thickness of a steel sheet can be customized during the manufacturing process according to the specific needs of the customer. This customization allows for versatility and flexibility in using steel sheets for a wide range of purposes, from construction and automotive industries to manufacturing and fabrication processes. Customizing the thickness of steel sheets ensures that they meet the specific strength, durability, and structural requirements of the project at hand.

- Q: What is the average wind load capacity of steel sheets?

- The average wind load capacity of steel sheets can vary depending on various factors such as sheet thickness, size, shape, and the specific steel material used. It is typically determined by conducting engineering calculations and considering local building codes and standards. Therefore, it is not possible to provide a specific average wind load capacity without knowing the specific details of the steel sheets in question.

Send your message to us

Hot Rolled Plate Steel Cheap Price 2016 New Desigh

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords