Hot Rolled Plate Steel 2016 New Desigh With Cheap Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

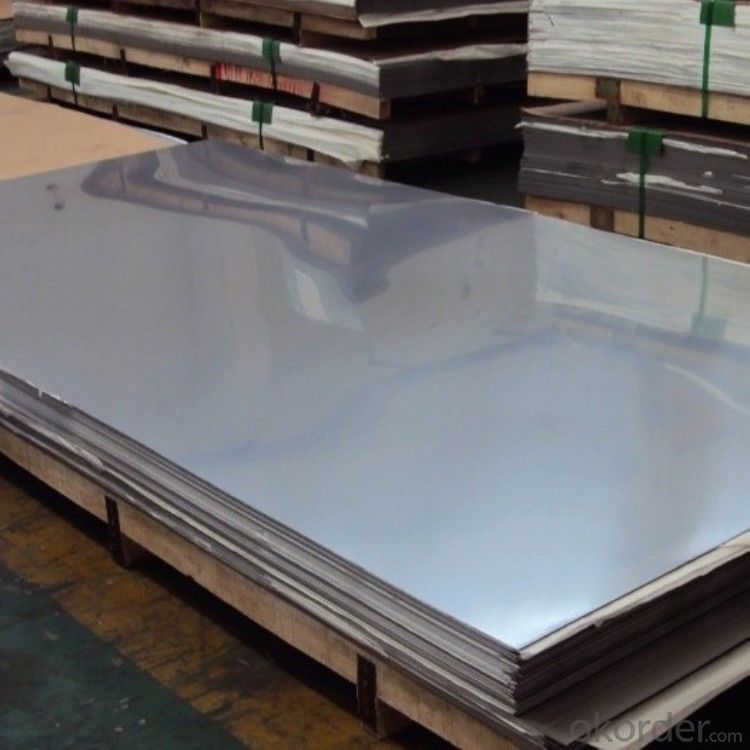

DESCRIPTION:

GRADE: SS400, ASTM A36, A572, ST37,ST52, Q195, Q215, Q235,Q345, S235JR etc.

STANDARD: GB/T709-2006, ASTM A36, JIS G3101, DIN EN 10025, SAE 1045, ASTM A570

SPEC: 1)Width: 600-2500mm or 1000,1050,1250,1500,1800,2000mm

2)Thickness:1.5mm-200mm or as customers’ special requirements;

3)Length: 2-12m or as customers’ special requirements

PACKING:

1.Big thickness:by bulk vessel

2.Small thickness:packed by steel strips and shipped by container

3.According to the requirements of customers'

TRADE TERMS :FOB, CFR, CIF

DETAILED PICTURES FOR STEEL COILS

FAQ:

Q:Do you have OEM service?

A: Yes.Variety of products size,quality and quantity can be customized according to your need.

Q:Could you support free sample?

A:Yes.We can supply FREE samples.But the delivery charges will be covered by our customers.

Q:How about the delivery time?

A:Within 15-30days after receiving the deposit or L/C at sight.

- Q: How do you cut a steel sheet?

- In order to cut a steel sheet, it is necessary to utilize the correct tools and techniques. The following are several commonly employed methods: 1. Power tools: An angle grinder equipped with a cutting disc is the most frequently used power tool for cutting steel sheets. While operating the grinder, it is essential to wear safety goggles and gloves. Begin by marking the cutting line on the sheet using a marker or chalk. Then, slowly and steadily maneuver the grinder along the marked line to cut through the steel. 2. Shears: For thin steel sheets, manual or electric shears can be employed. These tools possess a scissor-like cutting mechanism specifically designed for cutting metal. Position the steel sheet between the shears' blades, aligning the cutting line with them, and apply consistent pressure to cut through the sheet. 3. Plasma cutting: This technique is most suitable for thicker steel sheets. Plasma cutting involves the utilization of a high-velocity jet of ionized gas (plasma) to melt and sever the metal. Specialized equipment, such as a plasma cutter utilizing an electric arc to generate the plasma jet, is necessary for this method. 4. Waterjet cutting: Another effective method for cutting steel sheets is waterjet cutting. This method employs a high-pressure jet of water mixed with an abrasive substance, such as garnet, to cut through the metal. Although this technique is ideal for intricate shapes and precise cuts, it requires specialized machinery. Prioritizing safety is of utmost importance before attempting to cut a steel sheet. It is crucial to wear suitable protective gear, like safety glasses, gloves, and, if necessary, a face shield. Additionally, ensure that the work area is well-ventilated to prevent inhaling any fumes or particles produced during the cutting process.

- Q: What is the average fire rating for steel sheets?

- The average fire rating for steel sheets can vary depending on various factors, such as the thickness of the sheet, the type of steel used, and the specific fire testing standards that are being followed. Typically, steel sheets have a fire rating ranging from 30 minutes to 2 hours. However, it is important to note that fire ratings can be enhanced by incorporating additional fire-resistant materials or by using fire-resistant coatings on the steel sheets. It is always recommended to consult with fire safety experts or refer to the specific fire testing standards to determine the exact fire rating for a particular type of steel sheet.

- Q: Are the steel sheets resistant to chemical spills?

- Yes, steel sheets are generally resistant to chemical spills due to their inherent corrosion resistance properties.

- Q: Can steel sheets be used in architectural applications?

- Yes, steel sheets can be used in architectural applications. Steel sheets are versatile, durable, and offer structural integrity, making them suitable for various architectural uses such as roofing, cladding, and facades. Additionally, steel sheets can be easily shaped, allowing for creative and unique designs in architectural projects.

- Q: What are the different surface finishes for galvalume steel sheets?

- Some of the different surface finishes for galvalume steel sheets include regular spangle, minimized spangle, and zero spangle.

- Q: What is the difference between a perforated and non-perforated steel sheet?

- The designs and functionalities of perforated and non-perforated steel sheets distinguish them from each other. Perforated steel sheets are characterized by evenly distributed small holes or perforations on their surfaces, which can vary in shape and size depending on specific application requirements. The main purpose of a perforated steel sheet is to enable the flow of air, light, sound, and liquids through the sheet while maintaining its structural integrity. This makes it highly suitable for applications where ventilation, filtration, or visibility is crucial. Industries such as architecture, automotive, manufacturing, and construction commonly utilize perforated steel sheets for purposes like acoustic panels, protective barriers, decorative elements, and filter screens. On the contrary, non-perforated steel sheets lack any holes or perforations on their surfaces. They are solid sheets of steel primarily used for applications where strength, durability, and resistance to impact or abrasion are significant factors. Structural engineering, machinery, shipbuilding, and heavy-duty equipment manufacturing often rely on non-perforated steel sheets as they provide a sturdy and dependable surface for load-bearing and other demanding applications. To summarize, the distinction between perforated and non-perforated steel sheets lies in their design and functionality. Perforated steel sheets possess small holes throughout their surfaces, allowing the passage of air, light, sound, and liquids. Non-perforated steel sheets, on the other hand, are solid sheets without any holes, providing strength and durability for heavy-duty applications.

- Q: What are the different fastening options for steel sheets?

- Some common fastening options for steel sheets include screws, nails, rivets, and welding. Screws are often used for attaching steel sheets to metal or wood frames, while nails are commonly used for temporary or lighter applications. Rivets provide a secure and permanent fastening method, often used in industrial or structural settings. Welding is another option, involving the fusion of steel sheets together using heat. Each fastening option has its advantages and is chosen based on the specific requirements of the application.

- Q: What does steel plate "A3" mean?

- It can be used in all kinds of grinding tools, handles and other unimportant Abrasives parts

- Q: Are steel sheets resistant to radiation?

- No, steel sheets are not inherently resistant to radiation.

- Q: What is the hardness of the steel sheets?

- The specific grade and treatment of steel can cause variations in the hardness of steel sheets. The Rockwell hardness scale is commonly used to measure the resistance of steel sheets to indentation. The hardness of steel sheets can vary greatly, ranging from soft to extremely hard, and is influenced by factors like carbon content, alloying elements, and heat treatment methods employed in manufacturing. When choosing steel sheets, it is crucial to consider the intended application and desired properties, as the hardness can impact wear resistance, strength, and machinability.

Send your message to us

Hot Rolled Plate Steel 2016 New Desigh With Cheap Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords