Hot Rolled Alloy Structural Steel Round Bar SCM440

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Alloy Structural Steel Round Bar SCM440

Technical Paramenters

| Standard | Grade | C | Cr | Mo | Si | Mn | P | S | Ni | Cu |

| GB | 42CrMo | 0.38-0.45 | 0.90-1.20 | 0.15-0.25 | 0.17-0.37 | 0.50-0.80 | 0.035 | 0.035 | 0.3 | 0.3 |

| JIS | SCM440 | 0.38-0.43 | 0.90-1.20 | 0.15-0.30 | 0.15-0.35 | 0.60-0.90 | 0.03 | 0.03 | 0.25 | 0.3 |

| ASTM | 4140 | 0.38-0.43 | 0.80-1.10 | 0.15-0.25 | 0.15-0.35 | 0.75-1.00 | 0.035 | 0.04 | — | — |

| ENISO | 42CrMo4 | 0.38-0.45 | 0.90-1.20 | 0.15-0.30 | ≤0.40 | 0.60-0.90 | 0.035 | 0.035 | — | |

| Grade | aisi4140 astm4140 sae4140 42CrMo,1.7225,scm440,42CrMo4 |

| Processing | EAF+LF+VD |

| Commodity | steel round bar/round steel bar/round bar steel |

| Technique | hot rolled |

| Diameter | 10-310mm |

| Length | canbe required to 3-12m |

| Sizes tolerance | length: +/-100mm,straightless:3mm/m |

| Application | 1) General service industries (petroleum, food, chemical, paper, fertilizer, Fabric, aviation and nuclear) 2) Fluid, gas and oil transport 3) Pressure and heat transmission 4) Construction and ornament 5) Boiler heat exchangers |

| Advantages of this material | 1) High fatigue strength and impact resistance after tempering 2) Good low-temperature impact toughness 3) No obvious temper brittleness |

| Quality Condition | 1): Straightness: 3mm/m (max) 2): Corner Radius: 3(max) 3): The ends will be end cut or gas cut 4): No cracks on the surface |

| Packing | 1): Paint oil on the surface to protect steel bars from rusting. 2): Bundle packing by Iron Strips. 3): Bundle weight is from 2mt to 3 mt. 4): Two or three tags will be attached on each bundle. |

| MOQ | 5 tons for each sizes |

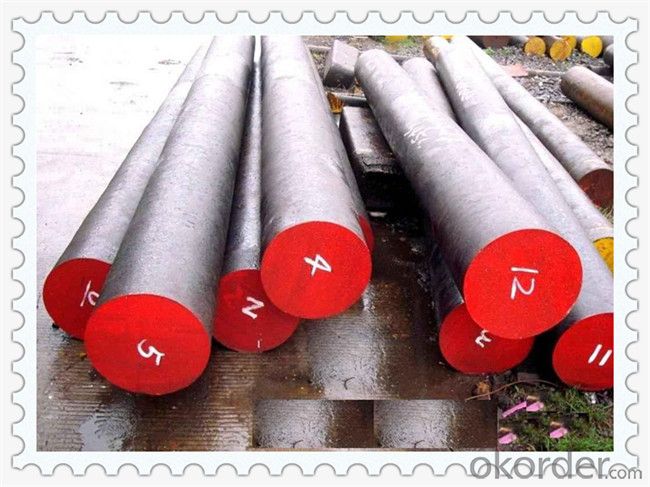

Products Show

Product Overviews

| Product Name | Typical Grades | Diameter(mm) | Standard adopted |

| Carbon Steel | 20 (1020/S20C/C22) | Ø16-Ø300 |

GB/SAE/JIS/DIN

|

| 40 (1040/S40C/C40) | |||

| 45 (1045/S45C/C45) | |||

| Bearing Steel | GCr9 (51100/SUJ1) | Ø12-Ø250 | |

| GCr15 (52100/SUJ2/100Gr6) | |||

| GCr9SiMn (A485-Gr.1/SUJ3) | |||

Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) | Ø12-Ø250 | |

| 40Cr (5140/SCr440/41Cr4) | |||

| 42CrMo(4140/SCM440/42CrMo4) | |||

| Gear Steel | 20CrNiMo | Ø16-Ø600 | |

| 20CrMn(5115/SMnC420/20MnCr5) | |||

| 20CrNiMo(8620/SNCM220/20CrMiMo2) |

Application

| Carbon Steel | Mold bottom, Plastic mold, Construction machinery parts Automobile parts, Security grills, Screens, Construction |

| Bearing Steel | Aerospace, Navigation, Nuclear energy, Chemical industry Electronic information, Petrochemical, Instrument and meter Transportation |

| Cr-Mo Steel | Mechanism & Fasteners gear, Stressed components for vehicles Engines and machines, Parts of larger cross-section |

| Gear Steel | All kinds of gears, Statically and dynamically stressed component for vehicles Engines and machine, Larger cross-section parts, Crankshafts |

Work Shop

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

- Q: What are the quality control measures for steel round bars?

- The quality control measures for steel round bars typically include visual inspection, dimensional checks, chemical composition analysis, mechanical testing, and surface finish evaluation. These measures help ensure that the round bars meet the required specifications and standards, guaranteeing their strength, durability, and overall quality.

- Q: How are steel round bars used in the manufacturing of heat exchangers?

- Steel round bars are commonly used in the manufacturing of heat exchangers due to their unique properties that make them suitable for this application. Heat exchangers are devices that transfer heat between two or more fluids, and steel round bars play a crucial role in their construction. One major use of steel round bars in heat exchangers is for the fabrication of the heat exchanger tubes. These tubes are responsible for carrying the fluids that need to be heated or cooled. Steel round bars are often used as the base material for these tubes due to their high strength and excellent heat transfer properties. The round shape of the bars allows for easy fabrication of the tubes, ensuring a tight and secure fit. Additionally, steel round bars are used to construct the headers and tube sheets of heat exchangers. The headers are the component that allows the fluid to enter and exit the heat exchanger, while the tube sheets hold the tubes in place. These components require high strength and durability to withstand the pressure and temperature differentials that occur during heat exchange. Steel round bars provide the necessary strength and stability to ensure the proper functioning of the heat exchanger. Furthermore, steel round bars are also used in the manufacturing of the support structures or frames of heat exchangers. These structures provide stability and support to the heat exchanger components and ensure proper alignment and positioning. Steel round bars offer excellent structural integrity and can withstand heavy loads, making them ideal for this purpose. In conclusion, steel round bars are an integral component in the manufacturing of heat exchangers. Their high strength, excellent heat transfer properties, and durability make them suitable for fabricating the tubes, headers, tube sheets, and support structures of heat exchangers. By utilizing steel round bars, manufacturers can ensure the efficiency, effectiveness, and longevity of heat exchangers in various industries, such as power generation, chemical processing, and HVAC systems.

- Q: What is the maximum temperature that steel round bars can withstand?

- The maximum temperature a steel round bar can tolerate depends on the grade or type of steel used. In general, carbon steel can endure temperatures of up to approximately 1,482 degrees Celsius (2,700 degrees Fahrenheit) before its structural integrity starts to deteriorate. However, it is worth noting that the maximum temperature tolerance of steel can be altered by different alloying elements and manufacturing processes. For instance, stainless steel can withstand higher temperatures compared to carbon steel because of its increased resistance to oxidation and corrosion. Additionally, the duration of exposure to high temperatures must be taken into account, as prolonged heat exposure can cause the steel to soften and eventually fail. Therefore, it is crucial to refer to the manufacturer's specifications or seek professional advice to determine the maximum temperature a specific steel round bar can endure in a given application.

- Q: How do you prevent steel round bars from rusting during storage?

- To prevent steel round bars from rusting during storage, it is important to keep them in a dry environment with low humidity. Applying a coating of protective oil or wax can also help create a barrier against moisture and prevent rust formation. Additionally, storing the bars off the ground and away from direct contact with concrete or other materials that may cause corrosion can further prevent rusting. Regular inspections and maintenance are crucial to ensure the bars remain rust-free.

- Q: Cold drawn steel wire is a round bar or thread steel in Construction Engineering?

- Cold drawn steel wire should be the same as round steel and thread steel! Their forming process and the meaning of the place used are different, and the quota is also different, cold drawn steel wire is cold drawn steel wire, strictly speaking, there is no mix together.

- Q: Can steel round bars be used for making railway tracks?

- Making railway tracks is possible using steel round bars. They are commonly chosen as the main material for railway tracks due to their strength, durability, and capacity to handle heavy loads. These bars offer a stable and solid base for train travel and can endure the continuous wear and tear caused by train wheels. The circular shape of the bars also aids in reducing friction and enabling smooth train movement. Moreover, steel is resistant to rust, which makes it appropriate for long-lasting outdoor applications like railway tracks. In conclusion, steel round bars are a favored option for creating railway tracks because of their strength, durability, and dependability.

- Q: Can steel round bars be used for making oil and gas industry components?

- Yes, steel round bars can be used for making oil and gas industry components. Steel round bars possess high strength and durability, making them suitable for various applications in the oil and gas industry, such as drilling equipment, pipelines, valves, and connectors. Additionally, steel's resistance to corrosion and extreme temperatures further enhances its suitability for these components.

- Q: What are the different surface treatments available for alloy steel round bars?

- Some of the different surface treatments available for alloy steel round bars include black oxide coating, galvanization, chrome plating, nitriding, and powder coating. Each treatment offers unique benefits such as enhanced corrosion resistance, improved wear resistance, increased hardness, and aesthetic appeal. The choice of surface treatment depends on the specific requirements and desired performance characteristics of the alloy steel round bars.

- Q: How do steel round bars perform under impact or shock loading?

- Steel round bars are known for their exceptional performance under impact or shock loading. Due to their high strength and toughness, steel round bars can withstand sudden forces and resist deformation or failure. The inherent properties of steel, such as its hardness and ductility, contribute to its ability to absorb energy and distribute it throughout the material, minimizing the impact on the structure. When subjected to impact or shock loading, steel round bars undergo plastic deformation, which allows them to absorb the applied energy without breaking. The ability to absorb energy is crucial in various applications, such as construction, automotive, and machinery industries, where components are often subjected to dynamic loads. Additionally, steel's excellent fatigue resistance further enhances its performance under impact or shock loading. Even when subjected to repeated impacts, steel round bars can withstand the cyclic loading without undergoing significant degradation in their mechanical properties. Moreover, steel round bars can be further enhanced through various heat treatment processes, such as quenching and tempering, to improve their resistance to impact or shock loading. These processes help to refine the microstructure of the steel, resulting in increased strength, toughness, and hardness. In conclusion, steel round bars have a remarkable performance under impact or shock loading. Their high strength, toughness, and ability to absorb energy make them reliable and widely used in applications where sudden forces or dynamic loads are expected.

Send your message to us

Hot Rolled Alloy Structural Steel Round Bar SCM440

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords