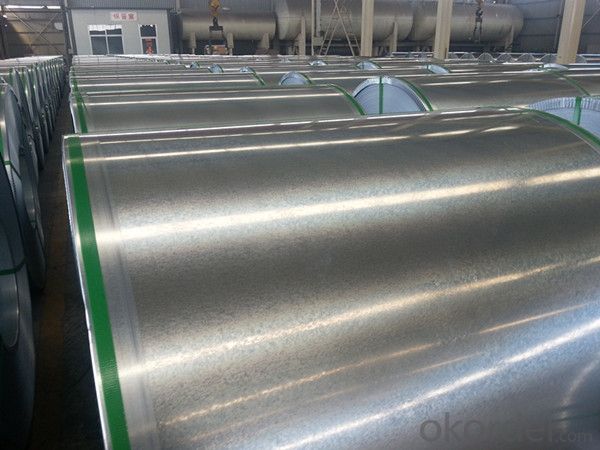

Hot Dipped Galvanized Steel Strips from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Commodity | Hot dip galvanized steel coil and sheet |

Technical Standard: | JIS 3302 / ASTM A653 / EN10143 |

Grade | DX51D / DX52D/ DX53D/ S250,280,320GD |

Types: | Commercial / Drawing / Deep Drawing / Structural quality |

Width | 500/650/726/820/914/1000/1200/1219/1220/1250mm |

Thickness | 0.12-2.8mm |

Type of coating: | Galvanized |

Zinc coating | Z30-275g/m2 |

Surface Treatment | Chromed / Skin-pass/ Oiled/Slightly Oiled/ Dry/ Anti-fingerprint |

Surface structure: | Zero spangle / minimized spangle / regular spangle/ big spangle |

ID coil | 508mm or 610mm |

Coil weight | 3-8 MT per coil |

Package: | Properly packed for ocean freight exportation in 20''containers |

Application: | Industrial panels, roofing and siding for painting |

Price terms | FOB,CFR,CIF |

Payment terms | T/T or L/C |

Delivery time | Within 30 days |

Remarks | Insurance is all risks |

MTC will be handed on with shipping documents | |

We accept the third party certification test,such as SGS/BV |

Application:Floor board, factory stair boards, deck board, car boards ,staircases, lorry beds, elevator floors, general fabrication.

Material:Q195 Q225 Q235 Q345 A36 S235jr St37-2 SS400 and so on

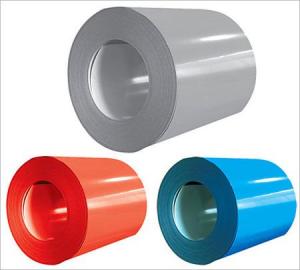

Uses: fridge ,air conditioner, washing machine and household appliances, automobile,steel furniture, drum, motorcycles, fitting apparatuses, furniturem,builings electronic telecoms and gas- conveyance projects.

- Q: What are the different methods of cutting steel coils?

- There are several methods of cutting steel coils, including shearing, slitting, laser cutting, and saw cutting.

- Q: On a free standing carport with an 8 inch, 22 foot long aluminum i-beam, would a steel 8-inch i-beam be just as strong? I am looking into it since they are cheaper.

- Yes-- just make sure that your connection to the beam is secure. Since you call it an I beam -- I assume that it is steel. Don't do any drilling -- use two heavy duty c-clamps to hang your bar from.

- Q: I need a machine which can produce steel pipes, but I don't know where to look...If you want me to state dimensions etc. just say...Thanks :)

- I'll answer both those questions. Your first question is: Who can I buy a Steel Pipe Making Machine? To which I reply: anyone. I'd put great consideration on the age of the person you are giving this machine to, and perhaps their physical ability. Cripples don't work well with steel pipes. Unless you are...beating them with one. Second question is: Where can I buy a Steel Pipe Making Machine? My reply: OKorder, or Steel Pipe Makers Incorporated. You could probably just steal one out of their factories. They have billions, and the actual machines are no bigger than...a bus or two. Just pop one in your backpack on the way out. But honestly, I don't know where to get a steel pipe making machine. BUT! I do know where to get a steel pipe making machine making machine. Ask santa. (BTW: Why do you need the steel pipes? I smell conspiracy!)

- Q: How do steel coils contribute to thermal insulation in buildings?

- Steel coils do not directly contribute to thermal insulation in buildings. Steel coils are used in the construction of various building components, such as walls, roofs, and floors. However, these components need to be insulated separately using materials like foam, fiberglass, or mineral wool to provide thermal insulation.

- Q: How are steel coils processed and shaped into various products?

- Steel coils are processed and shaped into various products through a series of manufacturing processes. First, the steel coil is uncoiled and cleaned to remove any impurities. Then, it goes through a process called leveling, where the coil is flattened and straightened. Next, the steel is cut into the desired length or shape, using techniques like shearing or slitting. After that, it may undergo additional processes such as forming, bending, or rolling to give it the desired shape. Finally, the steel is often treated with coatings or finishes to enhance its durability and appearance.

- Q: Can steel coils be coated with phosphorescent materials?

- Yes, steel coils can be coated with phosphorescent materials.

- Q: I saw this really pretty ring online and it was made of steel. Is this a good ring? If I were to wash my hands with it on, would it rust and turn my finger green?

- Steel rust is brown not green! Very much expected to be of one type of stainless steel, and you should have no problem.

- Q: How are steel coils used in the manufacturing of industrial valves?

- Steel coils are used in the manufacturing of industrial valves as they provide the necessary material for constructing the valve bodies and other components. The steel coils are processed and shaped into the desired form, ensuring the valves are durable and can withstand high pressure and temperature conditions.

- Q: Can steel coils be coated with electrically conductive materials?

- Yes, steel coils can be coated with electrically conductive materials. This coating process enhances the electrical conductivity of the steel coils and allows them to conduct electricity efficiently.

- Q: What are the different types of steel grades used for coil production?

- There are various types of steel grades used for coil production, including carbon steel, stainless steel, and high-strength low-alloy (HSLA) steel. These grades are selected based on the specific requirements and application of the coils, such as strength, corrosion resistance, and formability.

Send your message to us

Hot Dipped Galvanized Steel Strips from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords