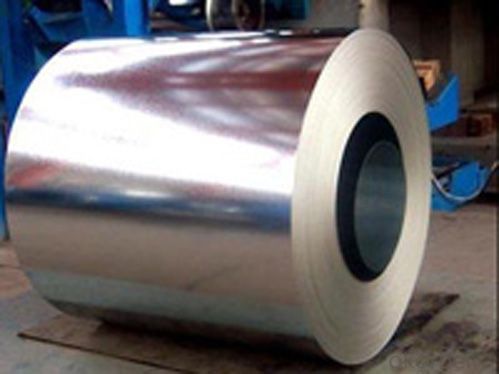

Hot dip galvanzied steel sheet in coils

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000Mt m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

SPECIFICATION:

Thickness:0.18-1.2mm

Width:680-1250mm

Zinc:40-140g

Spangle:zero spangle

Surface:chromate,skin pass, oiled/unoiled

Inner diameter:508 or 610mm

Coil weight:3-20Mt

If you have any need of GI or PPGI coil, please tell me the specification, then the best price will be sent to you immediately!

Alena

- Q: hello friends, I have some old 7.62x54r on stripper clips its nasty gunk on it can i use steel wool to glean it and still have it fire safely?

- * Yes, but I use both fine steel wool and Liquid Brasso Metal Polish on mine.* You can buy it at any Hardware and I believe Walmart carries it.* Great stuff.*

- Q: A friends of mine says he has balls of steel and i told him i would melt em off with lava. He said it wouldnt work. i disagree

- some lava is hot enough to melt steel. Mostly, though, the metal would react with the lava and get eaten up that way rather than directly melting. Most lava can contain an awful lot of iron and other metals without any difficulty and are rarely saturated with those metals.

- Q: What are the different types of steel coil coatings?

- There are several different types of steel coil coatings that are used for various purposes. Some of the most common types include: 1. Galvanized Coating: This is a zinc-based coating that provides excellent corrosion resistance to steel coils. It is often used in outdoor applications where the coils are exposed to harsh weather conditions. 2. Galvannealed Coating: Similar to galvanized coating, galvannealed coating also contains zinc, but it is heat-treated to form an alloy with the steel surface. This type of coating provides better paint adhesion and is often used in applications where the coated coils will be painted or further processed. 3. Pre-painted Coating: As the name suggests, pre-painted coatings are applied to steel coils before they are delivered to customers. These coatings can be made of various materials, including polyester, polyurethane, epoxy, or fluoropolymer. Pre-painted coils are commonly used in construction, automotive, and appliance industries. 4. Electro-galvanized Coating: This coating is applied to steel coils through an electroplating process, where a thin layer of zinc is deposited on the surface of the steel. Electro-galvanized coatings provide good corrosion resistance and are often used in indoor applications or where a thinner coating is desired. 5. Aluminized Coating: Aluminized coatings are made by applying a thin layer of aluminum to the surface of steel coils. This type of coating provides excellent heat resistance and is commonly used in exhaust systems, ovens, and other high-temperature applications. 6. Organic Coatings: Organic coatings are typically applied to steel coils to provide additional protection against corrosion and improve aesthetics. These coatings can be in the form of paints, lacquers, or powder coatings, and they can be customized to meet specific requirements in terms of color, gloss, and durability. Overall, the choice of steel coil coating depends on the specific application, environmental conditions, desired aesthetics, and performance requirements.

- Q: Why?Which one should i get? I am just starting to learn Guitar. Which one would be better for me? What is the difference? I already got the acoustic nylon but i might return it... if the steel is better.

- Depends on what kind of music you want to play. Nylon string guitars are used for classical music, and sometimes for jazz, occasionally for folk music. Steel string acoustic guitars are used for almost everything else -- rock, pop, country, bluegrass, folk, blues, jazz, you-name-it. Some people will tell you that beginners should start on nylon strings because they're supposed to be softer on your fingertips but unless you plan to continue playing classical or jazz or folk on your nylon string guitar for some time to come, you're wasting your money. If you want to play rock, pop, country or almost anything else, get a steel string guitar, put light-gauge steel strings on it. Your fingertips are going to be sore for the first few weeks no matter what kind of strings you have on your guitar -- you might as well start off on a guitar that will have the sound you want for the kind of music you actually want to play. Nylon string guitars also have wider necks and fingerboards than steel string guitars, so if you have smaller hands, a steel string guitar will probably be more comfortable for you to play. Hope this helps.

- Q: I feel really stupid asking this question but i feel like a put metal/steel strings on my classical guitar how do you tell the difference?

- Nylon strings are made of nylon; steel strings are made of .... if you put steel strings on your nylon string (classical style) guitar, you will destroy it. The instrument cannot stand up under the tension required for the strings, they will not fit in the saddle properly, they will cut the nut, and your machine heads may break. ... now if you're asking about the three lowest strings, those are metal wound around nylon on a nylon string guitar.

- Q: What are the dimensions of steel coils used in the oil and gas industry?

- The dimensions of steel coils in the oil and gas industry can differ based on the specific application and needs. Nevertheless, there are commonly used dimensions. Steel coils in the oil and gas industry typically possess a width that ranges from 600mm to 2000mm. The coil's outer diameter can vary from 800mm to 2200mm, while the inner diameter can range from 508mm to 610mm. The coil's weight can also vary, ranging from a few tons to several tens of tons. These dimensions are tailored to fulfill the requirements of diverse processes in the oil and gas industry, including pipe manufacturing, storage tank fabrication, and offshore platform construction. It is important to emphasize that these dimensions are not fixed and can be customized to meet the specific demands of each project.

- Q: What are the safety regulations for steel coil production facilities?

- The safety regulations for steel coil production facilities differ depending on the specific country or region. However, these facilities typically implement some common safety measures. One primary safety regulation is the proper training and education of employees. All workers in steel coil production facilities must undergo training on potential hazards and the correct safety procedures to follow. This includes training on handling heavy machinery, operating cranes or forklifts, and understanding the risks associated with working in a high-temperature environment. Maintenance and inspection of equipment are also important safety regulations. Regular inspections should be carried out to ensure that machinery and equipment are in good working condition and do not pose any safety risks. Moreover, maintenance procedures should be implemented to promptly address any issues or malfunctions. Fire safety is a crucial aspect of safety regulations in steel coil production facilities. Fire prevention measures like fire alarms, sprinkler systems, and fire extinguishers should be installed. Regular fire drills should also be conducted to ensure that all employees are familiar with evacuation procedures and can respond swiftly and effectively in case of a fire emergency. The use of personal protective equipment (PPE) is another vital safety requirement in steel coil production facilities. Employees must be provided with appropriate PPE such as safety glasses, helmets, gloves, and steel-toed boots to protect them from potential hazards like falling objects, sharp edges, and high temperatures. Additionally, safety regulations often necessitate the implementation of safety barriers and guards around machinery and equipment to prevent accidents and injuries. This includes safety gates, railings, and protective covers that restrict access to hazardous areas and prevent unauthorized entry. Regular safety audits and inspections should be conducted by relevant authorities or safety professionals to ensure compliance with safety regulations. Companies should also foster a culture of safety by encouraging open communication about safety concerns, providing safety training and refresher courses, and rewarding employees for adhering to safety protocols. It is important to note that safety regulations may vary across jurisdictions, and it is advisable to consult the specific regulations applicable in the country or region where the steel coil production facility is located.

- Q: I've heard different things bout them, though I do not know this. Oh, and if you know where you can buy some raw or get custom made stuff out of black steel please let me know it would be greatly appreciated. Oh and my friend told me there is a black steel that can be sharpened and silver will be underneath, is this also true? Thank you very much for answering ^^

- black steel and black tron are not same.

- Q: i want a good modern carbon steel (not stainless) knife. trying to keep it under 50$ also nothing to gruesome just a small pocket knife. thank you

- Well, okorder /... They did make other folders in M2 steel, but the thing is those are out of production and the cost is very high. Spyderco made M4 steel folder knives, and so did Benchmade. Although,both are outside of 50$ budget. I guess Opinels are best option.

- Q: I know copper pots are supposed to be really good for cooking with, and I have been looking around online. One thing I don't want to do, however, is send them in to be re-lined with tin. So I was wondering if stainless steel lined copper pots work as well as the traditional tin lined ones, or if those make the copper just for looks.

- Stainless steel is durable and does not disolve and make things taste funny. Stainless steel is not a good conductor of heat, so it has hot and cold spots. Copper is very good conductor. They noe bond copper to stainless steel to get the best features of each. Some pots just have a very thin copper plating to fool you. A good pot will be heavier, It is really hard to tell from looking.if it is plating or a bonded layer of copper. the thicker the better

Send your message to us

Hot dip galvanzied steel sheet in coils

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000Mt m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords